There’s no doubt about it: electric vehicles are here, and they’re not going anywhere. This is true both in the worlds of automotive and motorcycles, where manufacturers are racing to develop the best, most reliable technology out there. On top of that, massive incentives from governments all around the world look to accelerate this even further.

Indeed, we need not look far when it comes to governments making the push for electrification. In the US, the Biden administration has been aggressively encouraging local production, with the Department of Energy previously announcing funding of up to $3.1 billion towards battery manufacturing. Additionally, the department announced $192 million in funding for battery recycling initiatives, too. Naturally, this has prompted a lot of action in recent times, with companies now working towards ramping up US battery production.

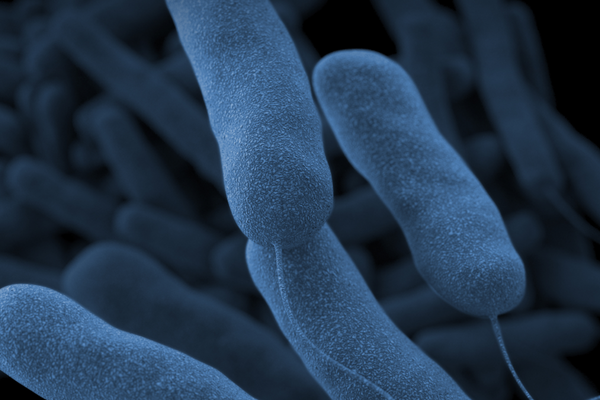

Lithium batteries are nothing new, as they’ve been powering our devices like laptops, smartphones, and tablets ever since they were invented. That said, the demand for lithium batteries has skyrocketed thanks to the growing popularity of electric motorcycles and cars, which make use of batteries several orders of magnitude larger than those found in smartphones.

To keep up with growing demand, BASF, a company specializing in battery materials production, has announced a partnership with Nanotech Energy, a company specializing in graphene-based energy products. The two will be working together to produce lithium-ion batteries with recycled materials, catering to the majority of the North American market.

On the BASF side of the equation, the company will be producing cathode active materials from recycled metals in its Michigan facility. Meanwhile, Nanotech will use these active materials to manufacture lithium-ion battery cells. In total, BASF hopes that the setup will reduce their carbon footprint by up to 25 percent.

To ensure the efficiency of their production, the two companies will also be working in tandem with the American Battery Technology Company (ABTC) and TODA Advanced Materials Inc. of Canada. Here, ABTC will recycle the materials used in Nanotech’s battery production – such as nickel, cobalt, manganese, and lithium. Once recycled, the materials will be turned over to TODA, who will then use them to produce battery precursors BASF needs for their production. The entire setup creates a closed-loop system consisting entirely of North American companies.

Commenting on the partnership, Daniel Schönfelder, the vice president of battery base metals and recycling of BASF, said in an article by The Verge, “Our partnership with Nanotech, ABTC, and TODA marks an important step for BASF’s global battery recycling business. Now, we are establishing the first closed-loop system in North America. This enables BASF and Nanotech to produce lithium-ion batteries with locally recycled content.”

.jpg?w=600)