This interview was originally published in the February 2009 issue of Guitar World.

The production line where Eddie Van Halen’s new EVH Wolfgang guitars are built delivers surprises and awe-inspiring sights around every corner. From the point where workers transform raw blocks of wood into the Wolfgang’s distinctive archtop body shape to the final setup section, where a few dozen white-, black-, and sunburst-finished models rest in quiet grandeur before shipment to their new homes, the factory buzzes with spirited activity.

But today’s most impressive sight is a collection of about 30 EVH Wolfgang guitars hanging in a corner of a workshop tucked away upstairs. One glance at these guitars provides an instantaneous visual history of this model’s development, from the early raw prototypes and numbered examples that were used to evaluate finish options, to an autographed version displaying Ed Van Halen’s final seal of approval, to finished production models.

Piles of pickups, necks, and miscellaneous guitar parts scattered on a table suggest hints of the painstaking effort that went into making this guitar.

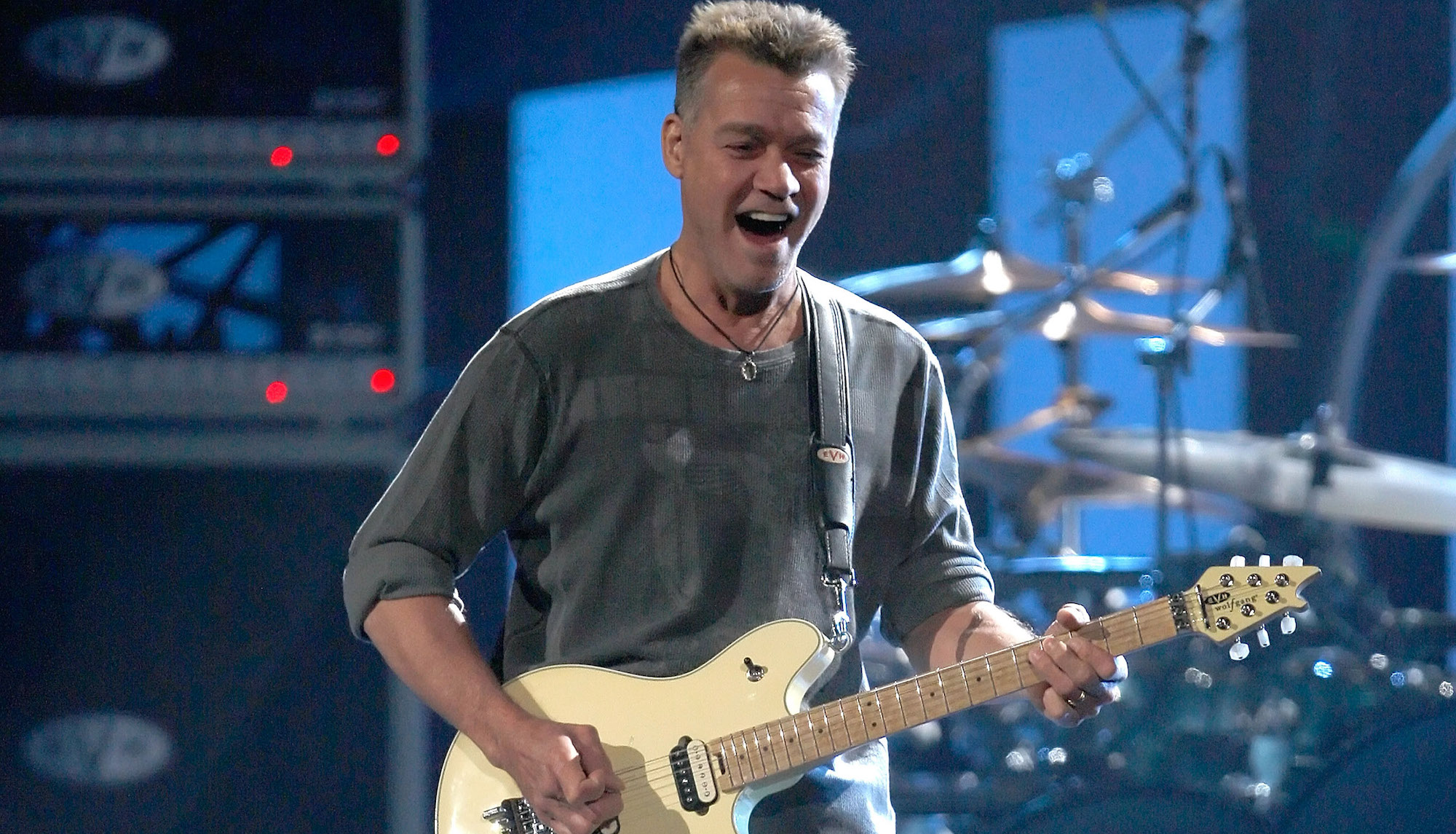

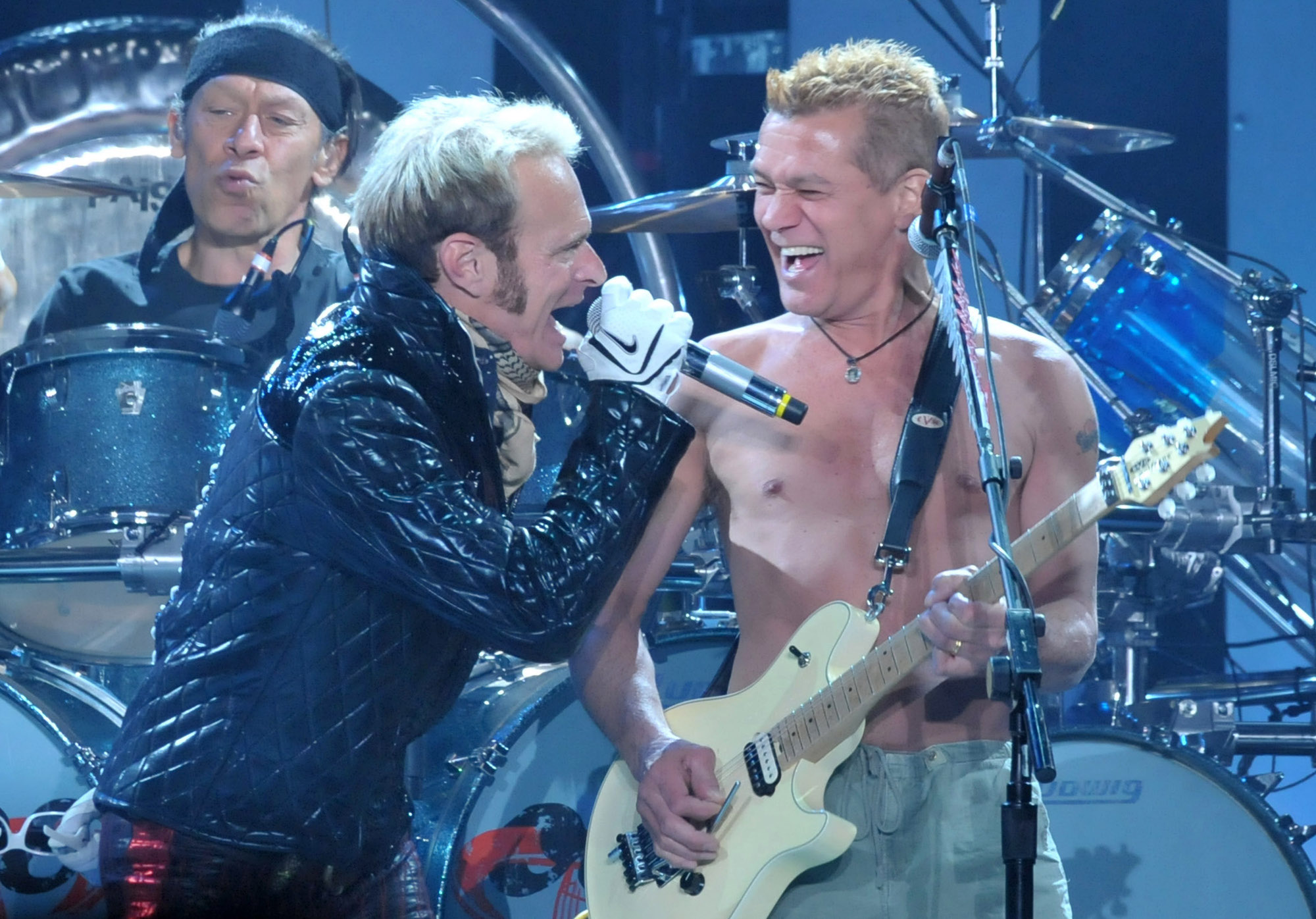

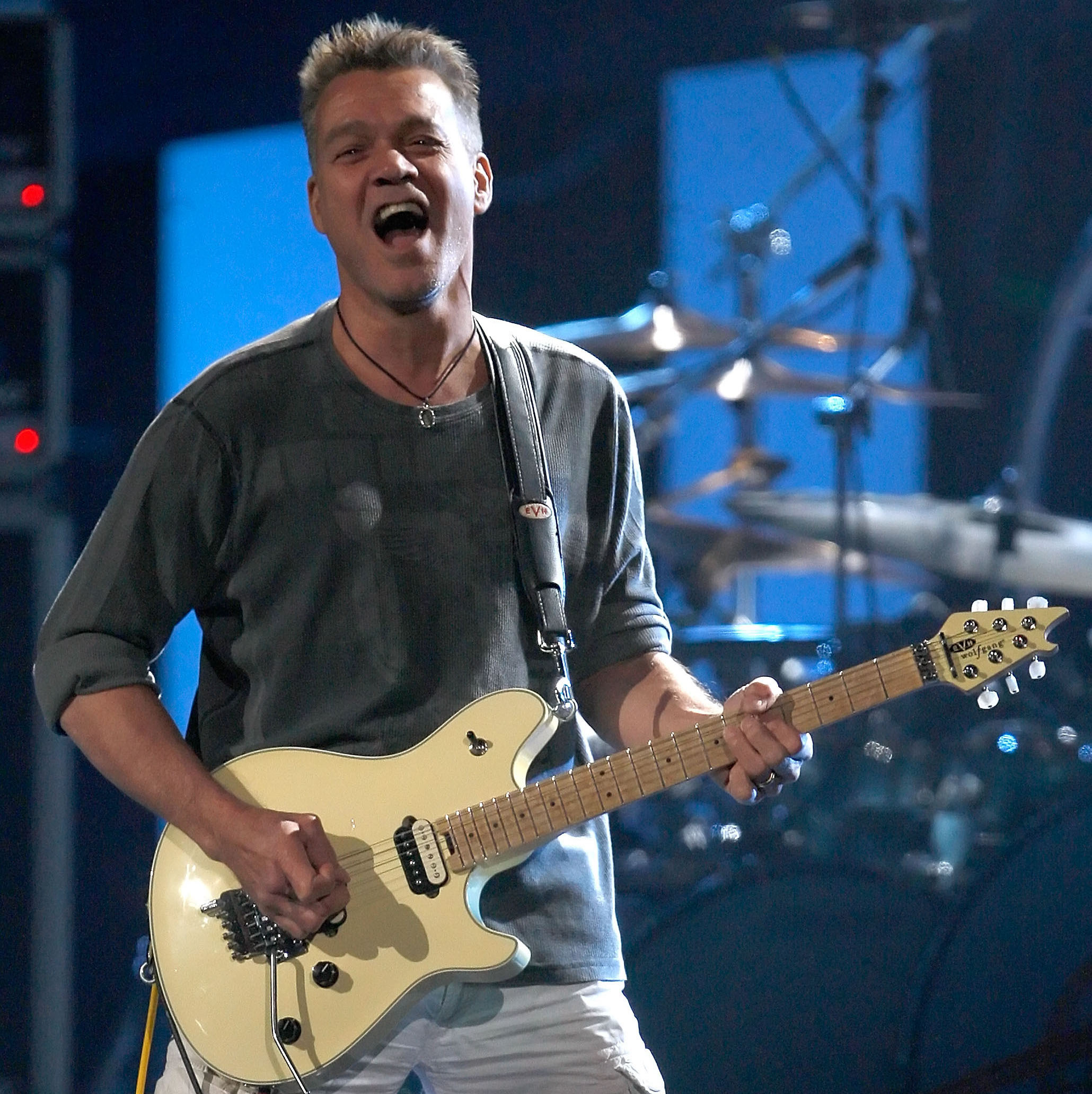

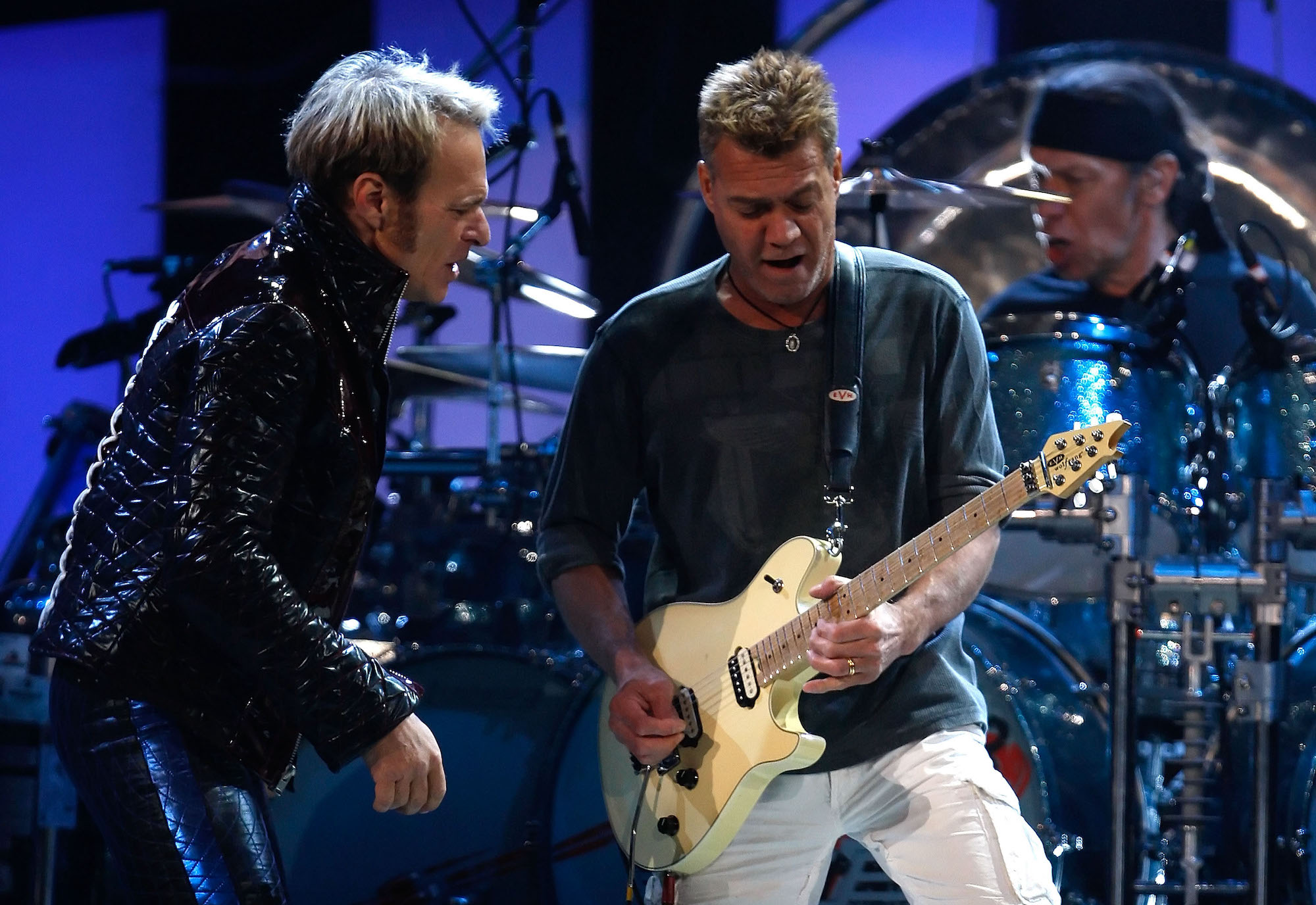

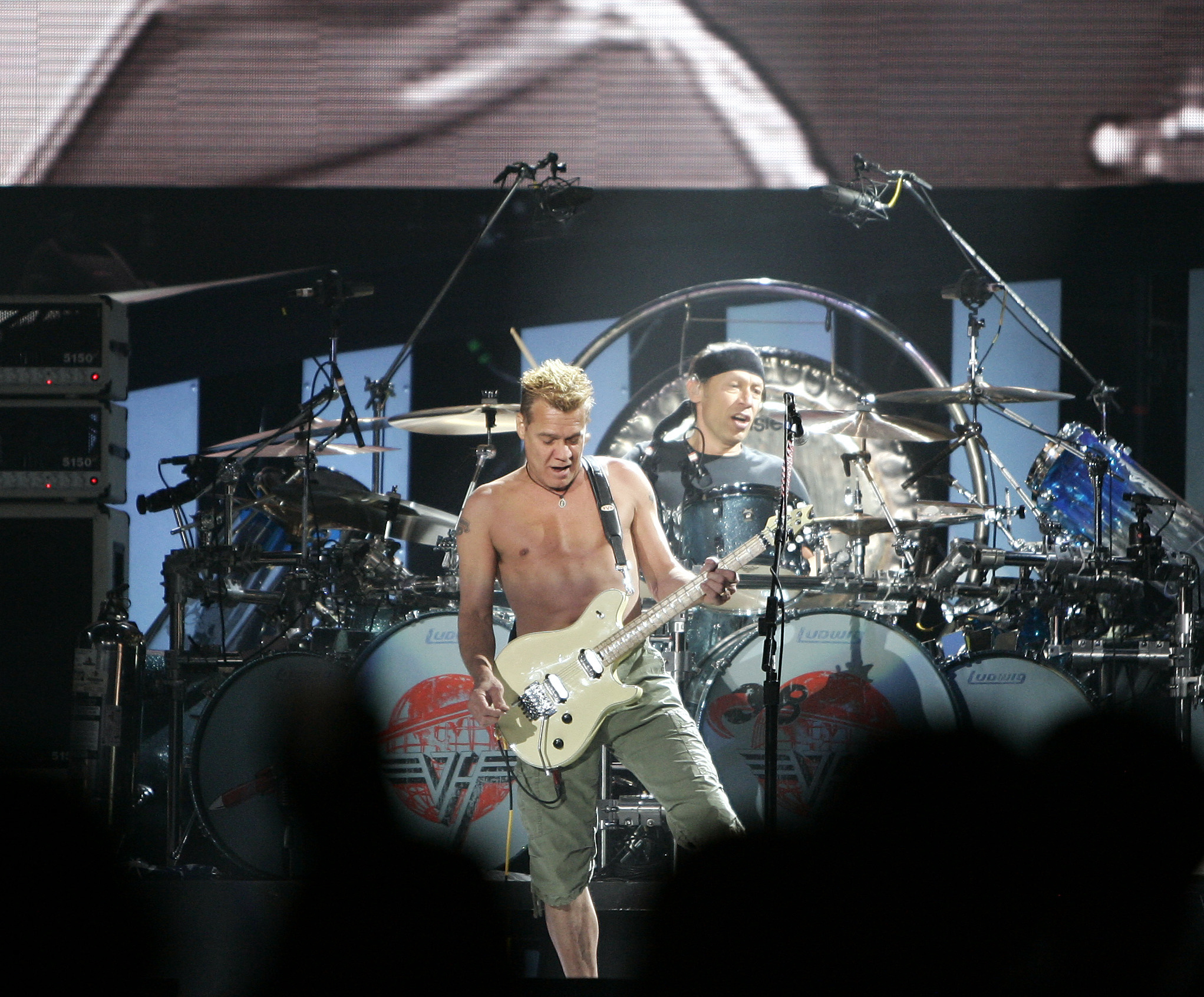

Ed Van Halen flashes his familiar smile as he pulls into the factory parking lot, but today it sparkles with distinct brilliance. Ed has plenty to be happy about these days, including the extremely successful Van Halen 2007-08 tour, which wrapped up in June. As Ed greets various staff members, he reveals that his girlfriend, Janie, who is accompanying him today, accepted his marriage proposal during their recent vacation in Hawaii.

Ed’s smile becomes blindingly radiant when he walks into the workshop and sees all of the various incarnations of the EVH Wolfgang guitar gathered in one place.

He began working on a new Wolfgang model in 2005 after he joined forces with FMIC (Fender Musical Instrument Corporation) to establish the EVH brand, but the project stagnated until Ed brought in Chip Ellis to collaborate with him in May 2006. (Chip had previously impressed Ed with his immaculate attention to detail on the EVH Frankenstein replica guitar.)

Ed, Chip, and Matt Bruck, Ed’s partner at EVH, spent more than two years on the project. Nearly nine of those months were spent refining pickup designs, and prototypes were road tested on the Van Halen tour for several months more.

Ellis maintained a diary that captured every excruciating detail that went into the EVH Wolfgang’s design, and it provides a fascinating glimpse at the passion of a master musician, his personal standards of quality and performance, and his unwillingness to compromise. Although Ed shared a few minor specifics about the new Wolfgang guitar in our three previous interviews, today he reveals how nearly every feature and detail of the guitar was changed, redesigned, or improved.

“The only thing that’s the same with the new Wolfgang is the body shape, and even that’s changed a little bit,” he says, comparing the EVH version with the previous Peavey model. “Everything else is different: the way the neck bolts on, the stainless-steel frets, tuning pegs, binding, pickups, tailpiece, pots, and more. The finish is extremely thin, and the cavity is left unfinished to let the wood breathe and age better. Even the output jack is different.”

Ed will formally introduce the EVH Wolfgang guitar to the public in January at the Winter NAMM convention, but today he’s invited Guitar World to an exclusive sneak preview.

Following a tour of the production line, Ed, Matt, Chip, and I return to the upstairs shop where we gather around a worktable and spend the next few hours discussing the project. But even as they express relief at reaching a milestone with the EVH Wolfgang guitar, it’s evident that this is just the start for this creative brain trust.

This guitar represents the evolution of everything you’ve learned about guitars from modifying, building, and designing your own instruments. Tell us about your quest to find your own sound and voice on the guitar.

Eddie Van Halen: “Ever since the beginning, everything that I picked up off the rack at a music store – even the custom-made stuff – did not do what I wanted it to. Either it didn’t have enough of something, or it had a bunch of Bozo bells and whistles that I didn’t need. A lot of it had to do with the fact that I never took lessons, so I didn’t know right from wrong. I didn’t know there were rules; I just knew what I liked and wanted to feel and hear. This also had a major impact on the way I play, doing things on the guitar that weren’t written in any books.

“I bought one of my first guitars from Lafayette Electronics, which was like a Radio Shack. They had a 12-string guitar that I really liked, but I didn’t want 12 strings; I wanted six. I asked the sales guy if I could take six strings off and try it out, and he said, ‘No.’ I said, ‘Why not?’ He said, ‘If you buy it, you can do whatever you want.’ So I bought it, took six strings off, and loved it! And that was my very, very first successful attempt at changing something that was considered standard to my liking.

I destroyed a lot of guitars trying to get them to do what I wanted, but I learned something from every guitar I tore apart

Eddie Van Halen

“Later I bought a Goldtop Les Paul with soapbar pickups, but I didn’t quite like the way they sounded. I wanted a humbucker. I got an old PAF from somewhere, took a chisel to make the pickup cavity bigger and crammed the pickup in the guitar. I only replaced the bridge pickup, not the neck one.

“Everyone who saw me play wondered how I got that sound from a soapbar pickup. They didn’t realize I put a humbucker in there because my right hand would cover the pickup when I would play; all they could see was the neck pickup. I wasn’t trying to fool anyone, but that was the sound I wanted. I also didn’t like the way the gold finish looked, so I painted it black.

“These were some of the first modifications I ever did to a guitar. Having the combination of two different pickups – which wasn’t available then – gave me more of what I wanted and was a hint of things to come, including the striped paint job.

“Then I bought a Gibson ES-335 that had one of those Maestro Vibrola wiggle sticks with the bent metal tailpiece, like you find on an SG. I liked it but it wouldn’t stay in tune. I figured that maybe I could make the E, A, and D string solid and just have the high three strings affected by the wiggle stick, so I sawed the Vibrola in half.

“My thought was that if the high three strings went out of tune, I would always be able to make it through a song playing chords that were on the low three strings that were in a fixed position – kinda like two guitars in one, a stop tailpiece and a wiggle stick on one guitar.

“I figured out how to hard-mount the low three strings, but I couldn’t figure out how to bolt the wiggle stick part into the wood. I drilled a hole and put a huge screw in it, and it worked a little bit, but after a while the wood gave out, amongst other problems.

“I destroyed a lot of guitars trying to get them to do what I wanted, but I learned something from every guitar I tore apart, and discovered even more things. Things like if the string is not straight from the bridge saddle to the nut, you’re going to have friction.

“On most guitars the headstock is angled back, which compounds the problem. When you press the vibrato bar down, the strings loosen from the bridge to the nut to the tuning peg. When you let up on the bar, the tuning does not return to the same point. So I got a brass nut, made the slots really big, and put 3-in-One oil in the cuts where the string travels through the nut. Then I wound the strings up the tuning peg instead of down so the line from the bridge saddle to the nut to the tuning peg was straight as an arrow.

“Also, from the back of the guitar where you put the string through the block on a Fender tremolo tailpiece, every time I turned the tuning peg I would grab the ball end and turn it with every turn of the tuning peg, alleviating twist tension within the string itself. It worked really well. These are some of the discoveries I made that allowed me to use a standard vibrato and do the crazy shit I do and keep the guitar in tune.

“I learned so many things along the way and incorporated all of them into building the Frankenstein guitar, which was originally painted black-and-white. On the first three or four Van Halen records, and especially live on tour, people were floored by how I could do all this crazy shit with a standard Fender tremolo and stay in tune.

“I continued to putz with every aspect of a guitar. I even tried winding my own pickups. One thing I never liked about most other guitars is that the front and rear pickups were the same. When I would get the rear pickup sounding great, the front one would sound like mud. I didn’t like that, so I tried winding the pickup less and more, using a heavier magnet, and a lot of different things.

“For years I used just one pickup because I couldn’t get the neck pickup to sound the way I wanted it to unless I changed the amp settings that were already dialed for the bridge pickup. I got different sounds through playing techniques. Then I hooked up with some pickup companies and asked them to make me a different neck pickup. That helped.

“When I designed my Music Man guitar, that was the first time that the neck pickup was totally different from the bridge pickup. Then I started experimenting with the distance where the pickup was placed and the way it reacts with the string. I use my finger as a gauge. It’s like this. [Ed plays harmonics on the low E string, working his way up the neck from the nut to the saddle.] There’s harmonic in the root. That’s where you want the pole piece centered.

“I’ve checked other guitars and they just stick the pickups anywhere. That can cause all these dissonant overtones that make you go, ‘Shit! Where the hell did that come from?’ Not many people know that. The pickup obviously picks up the sound from the strings. If it’s underneath a dissonant harmonic, it’s going to sound dissonant.

“I also couldn’t stand the high annoying feedback squeal that occurs playing at very high volumes. I thought maybe it was the actual coil windings vibrating that caused the feedback. I thought if I dipped a pickup in molten wax, when the wax cooled it would prevent the coil windings from vibrating. I took a coffee can, melted paraffin wax into it, dipped the pickup in the wax, and pulled it out right before the bobbins would melt.

“I didn’t always catch it in time. I ruined a lot of pickups that way. When I got it right… voila! It got rid of the squeal. This process I stumbled onto is now known as ‘potting,’ and it also became a standard process for manufacturing in the industry.”

A guitar is a very personal extension of the person playing it. You have to be emotionally and spiritually connected to your instrument

Eddie Van Halen

Although you’ve developed two previous signature models, you spent almost two years working with Chip to develop the new EVH Wolfgang guitar. Why did the process take so long?

“I’m constantly searching. We tore apart and analyzed every little thing on the new Wolfgang. If someone didn’t make something that was good enough for us, we found someone to make it.

“The new Wolfgang is a culmination of my 35 years of experimenting with guitars. Everything that I’ve destroyed, stumbled onto, learned, and experienced in my journey to get to where we are now is in this guitar. And there is a lot more to come.

“A guitar is a very personal extension of the person playing it. You have to be emotionally and spiritually connected to your instrument. I’m very brutal on my instruments, but not all the time. I’m not to the point where I’m like Pete Townshend and smashing the shit out of it after a gig. I wouldn’t do that to an instrument that is a part of me.

“I don’t need to do this for financial reasons. I could have just stayed at home and built this guitar for myself. I do this because a lot of people ask if they can get what I use. Well, yes you can, and what you get is identical to what I use.

“From the basics of the guitar to painstaking aspects like the binding and everything else, we redid everything on this guitar. That’s why it took so long. Thank God that Chip stuck it out, because I was driving everybody nuts.”

What was the most painstaking process about making this guitar?

Chip Ellis: “Developing the pickups.”

Van Halen: “Chip would show up with a new batch of pickups, and all I had to do was plug into the new 5150-III amp and hit one note. Chip would look at me confused, but I can really tell by one note. Explaining sound is like trying to explain what something looks like to a blind person. It’s very difficult. Over and over I would say, ‘It ain’t hitting me in the gut!’ It was either too shrill in the high end or too muddy. All it took was one note.”

Van Halen: “Eventually, anybody will hear it. But the feel is what’s really important. The harmonic overtones and the overall tone of a guitar all contribute to sustain and the feel, which has so much to do with how easy it is to play. A lot of factors come into play when it comes to making pickups, including placement, coil windings, and magnets, et cetera.”

Matt Bruck: “We went through about 80 sets of pickups.”

Van Halen: “The pickups were all great, but they weren’t what we were looking for. Ultimately, we decided to try making our own pickups.”

Ellis: “It was a matter of being able to sit down with an engineer, plug in and say, ‘You hear that? That’s what we’re trying to get rid of.’ We came really close with the first version we made in-house.”

Van Halen: “That’s because we had a lot more control. We weren’t on the phone trying to tell a guy, ‘Hey, warm it up. I want more sustain.’ I’m not saying the other companies couldn’t have done it. It just happened a lot quicker when we started making the pickups ourselves.

“Before we made that decision, I said, ‘Let’s try moving the pickup around.’ It was one of our last attempts to make things work. Chip wanted to take the guitar back to the shop to rout out a bigger pickup cavity. I said, ‘Let’s just do it now with a screwdriver and a chisel and make it bigger.’ I didn’t want to wait until the next day.”

Ellis: “That was a very important step. We ended up moving the pickup forward just a little bit.”

Van Halen: “It was only 1/32nd of an inch. The tolerance of things on this guitar is like NASA standards. It had to be tight, and it had to be quality.”

It would blow your mind how many variables are involved, and not just with the pickup but also with the reaction between the pickup and the wood and how it's wired

Eddie Van Halen

Ellis: “These pickups turned out to be very versatile. They can soothe your soul and caress you a little bit, but also slap you in the face.”

Bruck: “They cover the whole dynamic range – every nuance and articulation of playing.”

Van Halen: “It’s easy to play, and it has the sustain, harmonics, and feedback that you want. That’s how I can tell just by hitting one note. If it takes too long to feed back, it’s not picking up the right frequencies from the string.”

Ellis: “A lot of times when Ed would hit a note, there would be a long pause until feedback, and there would be a funny tone in between.”

Van Halen: “There was this nasty, ugly overtone.”

Ellis: “It had to be seamless.”

The neck on the new Wolfgang has a slim profile. The necks on your earlier models were more bulky.

Van Halen: “It was a matter of closing my eyes and feeling it. We went back to some of my earlier guitars, like the striped guitar I had back in 1984. That’s the way I like it to feel. It’s nice. It’s like a sexy woman.”

How did you choose the tuners?

Ellis: “Ed was rehearsing for the Van Halen tour, and I brought a bunch of different samples to him. The first thing he tried to do was break them. He’d go, ‘Why is this loose?’ So I handed him another batch. We ended up going with these tuners because they’re heavy duty. There was no ‘give’ anywhere. When you get a lot of tuners to pitch there’s a little bit of play. These are just as smooth and precise as can be.”

Bruck: “We looked at samples that were cut in half and examined the gearing. We made sure that the ratio was tight. The tuners and the switch were both made by Gotoh. They uphold quality and consistency.”

Van Halen: “A lot of times you’ll go to a vendor and they’ll give you something good, but when you need more the quality takes a nosedive. We’re very hard on vendors. There are so many Floyd Rose trems out there. A lot of people don’t realize that there is a difference. We concocted one that is the best there is. We went through all kinds of details like using a brass sustain block. It’s bulletproof, and it sounds better.”

The five-ply binding on the body and headstock really completes the guitar.

Van Halen: “That was Matt’s idea. When we were sitting down in the lounge narrowing down finish options, Matt started drawing on one of the bodies with a marking pen. Chip and I were going, ‘What the hell are you doing?’”

Bruck: “The previous Wolfgang had solid, one-piece binding. Ed talks about how the guitar is like a woman… I wanted something fancy. I thought that five-ply binding would be bitchin’. We want this guitar to stand alongside a Les Paul but to also be a modern day instrument. We want this guitar to be held at the same level of esteem.”

Van Halen: “I don’t want to sound arrogant, pompous or egotistical, but aesthetically I think this guitar is right up there with a Les Paul. And that’s besides all of the work and the quality of the actual instrument and the components. It’s simple, balanced, and it feels right. It looks great, too.

“If you have a great-sounding guitar that’s a quality instrument and a good amp, and you know how to make the guitar talk, that’s the key. It starts with the guitar and knowing what it should sound and feel like. Yesterday, I picked up the first two Wolfgang production models, and they felt even better than the main Wolfgang prototype that I used on the whole tour.”

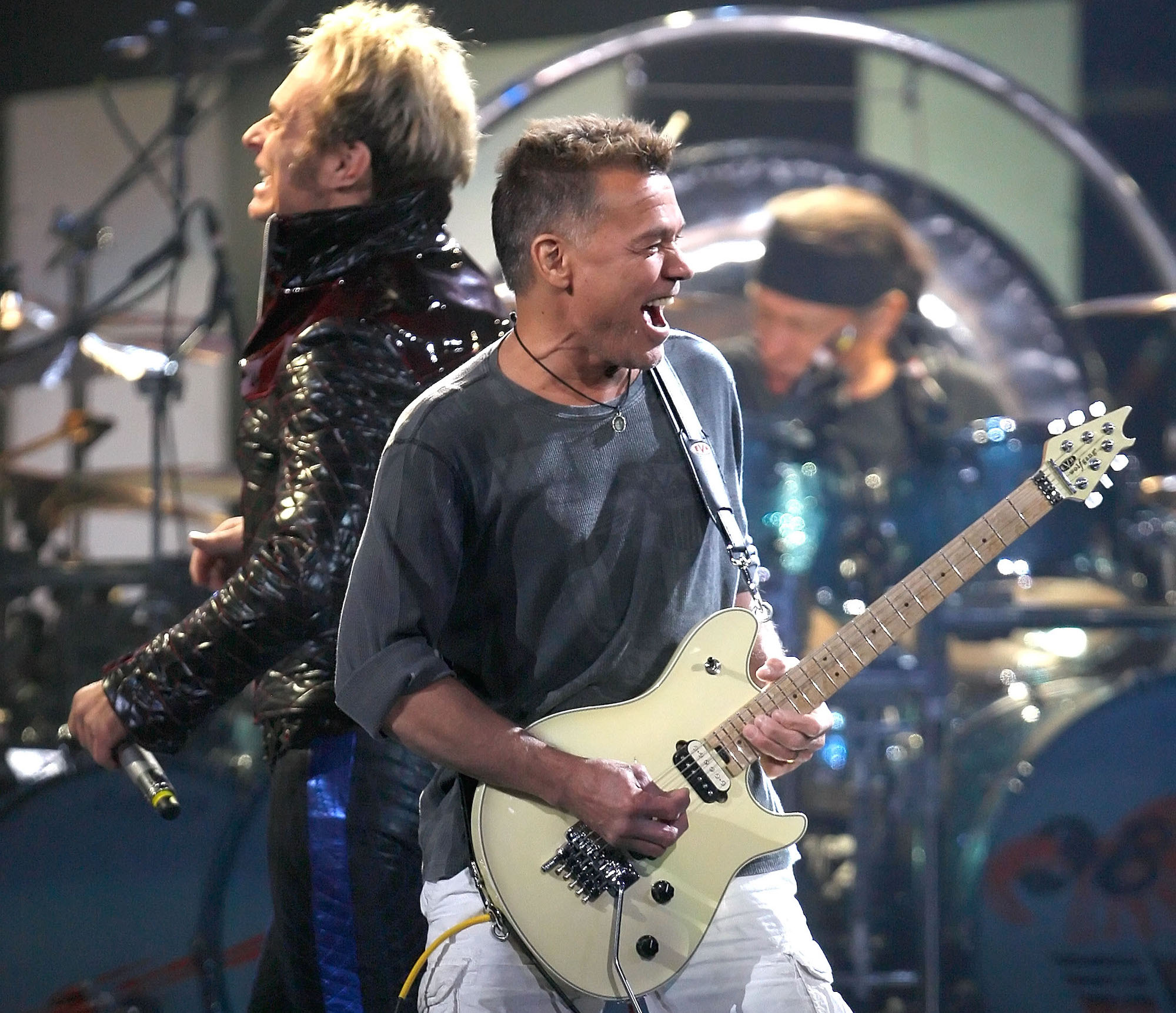

Taking this guitar on the biggest tour of the last two years to road test it was a very bold move.

Van Halen: “It had to be done. I don’t let anything out unless I’ve dragged it around the block, taken it out on tour, and beaten the living shit out of it. Playing on the road is an entirely different animal than playing in the studio. The guitar will get bounced around in the truck. You’ve got union guys slamming the cases around, and somebody might drop the guitar. The painstaking effort that we took starting from scratch alleviated a lot of problems, which gave me the confidence to take it on tour. The tweaks that we did on the road were very minor because of all the preparation that we did.”

The volume control is like my steering wheel. If it doesn’t turn light, smooth, and easy, and if it isn’t quality, I’m fucked

Eddie Van Halen

What developments came about from taking the guitar on the road?

Van Halen: “The stainless-steel frets were a major breakthrough because of the amount of playing and bending that I do. I have to get my guitars refretted every couple of months. On the whole tour, the frets were great. They didn’t wear out. Anyone who thinks they take away from the tone is crazy. It has nothing to do with tone.”

Ellis: “Before we tried using stainless-steel frets, Ed had the guitar only three weeks in rehearsal before the frets were gone. [Picks up Ed’s #4 prototype] You played this guitar for half of the tour, and the fret job looks brand new [due to the stainless-steel frets]. We fixed the jack plate first, because the one on this guitar almost fell out during the first show. We changed it to a square, four-screw jack plate.”

Van Halen: “Another big development was the pickup potting. After a while the windings started vibrating and creating that high squeal again. I asked Chip, ‘What are we going to do?’”

Ellis: “We decided to try double-dipping them. There was a little foam pad in the tremolo cavity, which I thought would be a good idea [to prevent feedback], but out the blue Ed asked me what was the deal with this black thing in the cavity. The guitar sounded a little muffled, and we thought it might be the pickup. When I went into the guitar pit Ed was in there ripping out the foam pad, going, ‘What the hell is this?’”

Van Halen: “We modified the volume pot, because when I’m playing Cathedral most pots freeze up when I’m doing the volume swells. I’m constantly turning down the volume between all the breaks and pauses within the songs.

“The volume control is like my steering wheel. If it doesn’t turn light, smooth, and easy, and if it isn’t quality, I’m fucked. I have to turn that thing up and down in an instant. I’m probably harder on it and use it more than anyone else, so it has to be durable.”

Bruck: “It’s a low-friction pot.”

Ellis: “We spent a couple of months going back and forth getting that right. Some of the first potentiometer samples we got from [electronic parts manufacturer] Bourns felt loose, so we made a few revisions.

“Many players spend a lot of time tweaking their guitars. With this guitar we’ve done all of that for you. There’s nothing left to do on it. Shame on you if you want to swap anything out on this guitar. You’re not going to find anything better.

“I’m surprised how versatile this guitar is. When I first got involved with this project I thought that we were just going to make something that was loud, nasty, and would squeal like a pig when you wanted it to. But we did a lot of testing on the clean channel of the 5150-II. This guitar cleans up so nicely. You can play anything with it.”

Bruck: “It’s Ed’s instrument, but it’s applicable to many different styles of music. I’m really excited to see who picks up on it.”

Van Halen: “It sounds great even when it’s not plugged in. I need a totally resonant body. That just makes sense to me. What makes an acoustic guitar sound better than others? The wood and its resonance. It’s the same with an electric guitar. The pickups are only there to amplify what the wood is doing.

We wanted to be able to visit any EVH dealer in the world on the day of the gig, grab a 5150 and a Wolfgang, and do the gig, and there would be no difference between it and Ed’s gear

Matt Bruck

“If you’re amplifying a body made out of concrete, it’s not going to sound very good no matter how good the pickups are. If the guitar sounds great unplugged, it should sound great when amplified, as long as you’ve paid attention to all the other aspects and details as we have.”

I understand that Chip made eight different guitars and numbered each one so you could test finish options without making biased assumptions.

Ellis: “Guitar number 4 won the battle in the batch of eight guitars that we made. We tried everything from rubbing gunstock oil on the body, to a sealer, to thin-skin lacquer, heavy polyester, and thick urethane. We ended up going with a very thin acrylic finish.”

Van Halen: “And we left parts of the body exposed, so it breathes. A violin isn’t sealed or clear coated on the inside of the body. With age it will only sound better.”

Bruck: “Whatever you put on top of the wood dampens its resonating capability.”

Ellis: “This doesn’t look like the typical production guitar that’s covered in clear finish and everything is smooth as can be. It is more like a violin. The finish is thin enough that it doesn’t negatively affect the sound. The finish is another essential part of the instrument.”

You influenced many of the biggest guitar design advancements over the past 30 years, like the Floyd Rose tremolo and the D-Tuna. What’s next?

Van Halen: “I don’t sit around and think about what other people would like. I think about things that I want and need. That’s where everything starts. I’ve got a patent on the Drop to Hell tailpiece.

“I’ve always been into down tuning, from the first record to Unchained to this day. I’ve replaced the low E string with a bass string. I always wanted to have a guitar where I could drop the low E string’s tuning in an instant. This bridge drops from E to A as quickly as you can flick the lever, and you can go anywhere in between or even lower if you want. And it’s built like a brick shit house. It will not break.”

Bruck: “The engineering precision on that tailpiece is incredible. Nothing is loose. And the concept has room to grow. It works on one string right now, but it could affect all six strings.”

Van Halen: “If you want what I use, we’ve made it available. The stuff that I use onstage isn’t modified. My modifications are built into my guitars and amps when they come off the line.”

Bruck: “One of the primary concepts of Ed having his own brand was that we wanted to be able to visit any EVH dealer in the world on the day of the gig, grab a 5150 and a Wolfgang, and do the gig, and there would be no difference between it and Ed’s gear.”

Ellis: “This guitar is designed around Ed’s setup, which is engineered into every one of these guitars that we make. Everything is precalculated. The neck pocket is set to exactly the right angle. The pickup cavities mount the pickups at the exact height where Ed likes it. We just screw them directly into the wood. The bridge sits flat in the cavity. You can literally take the body out of the paint department, put the neck, parts, and strings on it, and the action is exactly where it needs to be. Thanks to the graphite reinforcements that we put in the neck, it stays stable when we ship a guitar across the country.”

Van Halen: “My guitars get subjected to all kinds of crazy temperatures on tour. It can sit in the back of a cold truck for 16 hours and then be brought into a warm venue. Even during the walk from the dressing room to the stage the temperature can change drastically. I would turn the studio temperature down to about 55 degrees and then take this guitar out in the sun, and it wouldn’t change. And it’s so easy to adjust the truss rod. You just insert the Allen wrench and you’re done.”

Now that you’ve completed a new guitar and amp you must be very inspired. I would think that some new songs lurk in this gear.

Van Halen: “I’m always inspired. It’s things like the new Wolfgang and Drop to Hell tailpiece becoming a reality that keeps me pushing the limits of what’s possible. I’ll be making music ’til the day I die. I’ve done all kinds of stuff, and more is coming. I can’t tell you exactly when right now. Wolfgang is in the 12th grade, and he needs to graduate first. Then I’m getting married in June. We’ll pick it up after that.”

With this guitar it seems like you have come as close to perfection as ever. But it also seems like you haven’t stopped searching.

Van Halen: “I don’t know if there is such a thing as perfection. But this is the best of everything that we could find with these three minds making it happen. I’m always changing, so even ‘the best’ is a tough word for me to define.”

It’s very generous for you to share your knowledge with other guitarists and musicians. After all, you could have just turned this into a one-off custom instrument for yourself.

Van Halen: “That’s the whole point. It’s not just for me, it’s for everyone. We’re not just shipping stuff out for the almighty buck. The Wolfgang had better outlive me and last forever. My name and my son’s name are on it. It’s not a fad. It’s my 35 years of knowledge of what makes a sweet, sexy, toney, quality, indestructible instrument. I’m very proud of it.

“Initially, I was very worried about working with Fender because of all the bullshit you can go through with a huge company. But in a great way they proved me wrong. They rose to every occasion and gave me the freedom to create and bring my vision to fruition. Fender is my home. It took me a long time to get here, but it’s a good marriage, and I’m proud to have this team that has stuck with me through all of this.

“The best thing of all, when you do all the things we did and get and get those things right, you end up with a great instrument that will inspire anybody to make great music and enjoy it. This guitar just makes you want to play. After all you don’t work music, you play it!”

This interview was originally published in the February 2009 issue of Guitar World.