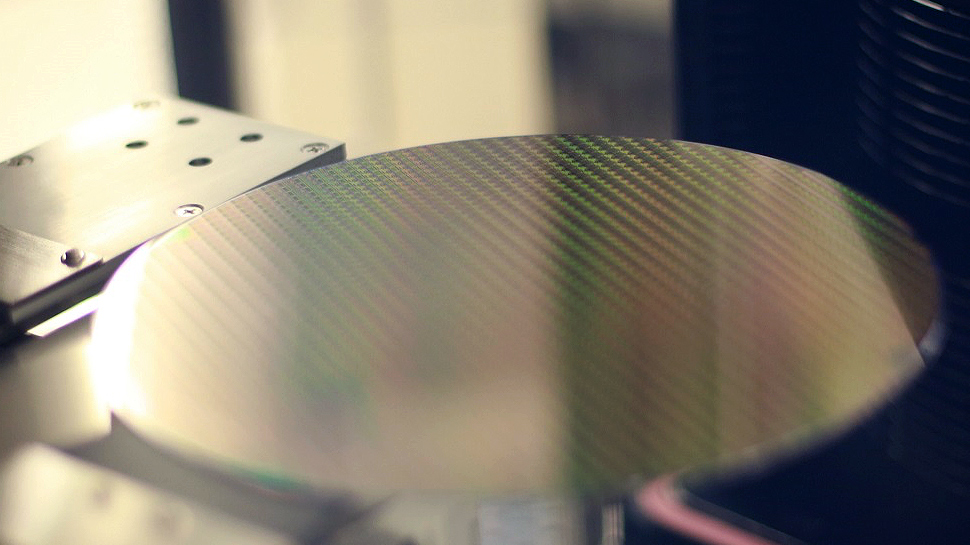

High-purity photoresists are essential for making chips on advanced production nodes. As China strides to build a self-sufficient semiconductor industry, it has to develop not only sophisticated chipmaking tools but also high-purity resists. In 2024, China made notable strides in photoresist development, supported by government initiatives and rising demand from local chipmakers, reports TrendForce.

Semiconductor photoresists are classified by exposure wavelengths, including broadband UV (300–450nm), g-line (436nm), i-line (365nm), KrF (248nm), ArF (193nm), EUV (13.5nm), and electron beam types. KrF, ArF, and EUV photoresists are the purest and the most advanced of all. The global market is dominated by major players from Japan and the U.S., such as JSR, Tokyo Ohka Kogyo, Shin-Etsu Chemical, Sumitomo Chemical, Fujifilm, and DuPont, who control most of the advanced photoresist technologies.

Chinese companies, including Shanghai Sinyang, Rachem, and Bcpharma, have made progress in entry-level photoresists but struggle to compete in the high-end market due to technical challenges and a late start. Currently, China's domestic penetration rates remain low: approximately 20% for g-line and i-line photoresists, under 5% for KrF, and below 1% for ArF. However, there are Chinese companies making strides in the direction of advanced photoresists.

Hubei Dinglong recently announced that its ArF and KrF photoresists passed customer evaluations and received orders from two domestic wafer manufacturers, totaling over ¥1 million ($137 thousand). According to the report, the company achieved this by customizing monomer and resin structures and enhancing processes like purification and mixing, which enabled a fully localized production process covering both materials and final products.

Rongda Company secured approval for a ¥244 million ($33.493 million) private placement to fund high-end photoresist projects, IC substrate solder masks, and dry films. These funds will support R&D costs and operational needs. Rongda's dry film products are aimed at the PCB and semiconductor industries, which are experiencing strong growth due to increased production capacity in China.

China's rapidly expanding microelectronics manufacturing base increases demand for localized photoresist solutions as new fabs come online. China's government actively supports the semiconductor and raw materials industries with policies to encourage domestic innovation and reduce reliance on foreign suppliers.

While challenges persist due to high technical barriers set by global competition, the Chinese photoresist industry is gradually closing the gap, which promises to eventually expand the market share of these companies in high-end applications.