YouTuber and digital fabrication enthusiast Ivan Miranda has published a new video in his Giant 3D Printer series. After the final steps in fabricating and assembling this extraordinary device, we got to see some of the first samples of output. With a potential build volume of 1110 x 1110 x 2005 mm, the new 3D printer was ready for some gargantuan projects. So, what was Miranda's first idea? He couldn't resist making a life-size 3D printed copy of himself.

The above video starts by showing viewers the assembly of the 2.5 m³ build volume, using a frame made from sturdy 40 x 40 aluminum extrusion. Early in the new video, Miranda seems to apologize for using V-wheels to facilitate printing head the Z-axis movement, explaining that the choice was made due to budgetary concerns. While linear rails would be the best option, we appreciate that costs need to be kept in check. Moving the axes required Nema 23 stepper motors and a lot of 3D printed housings, screws and threads.

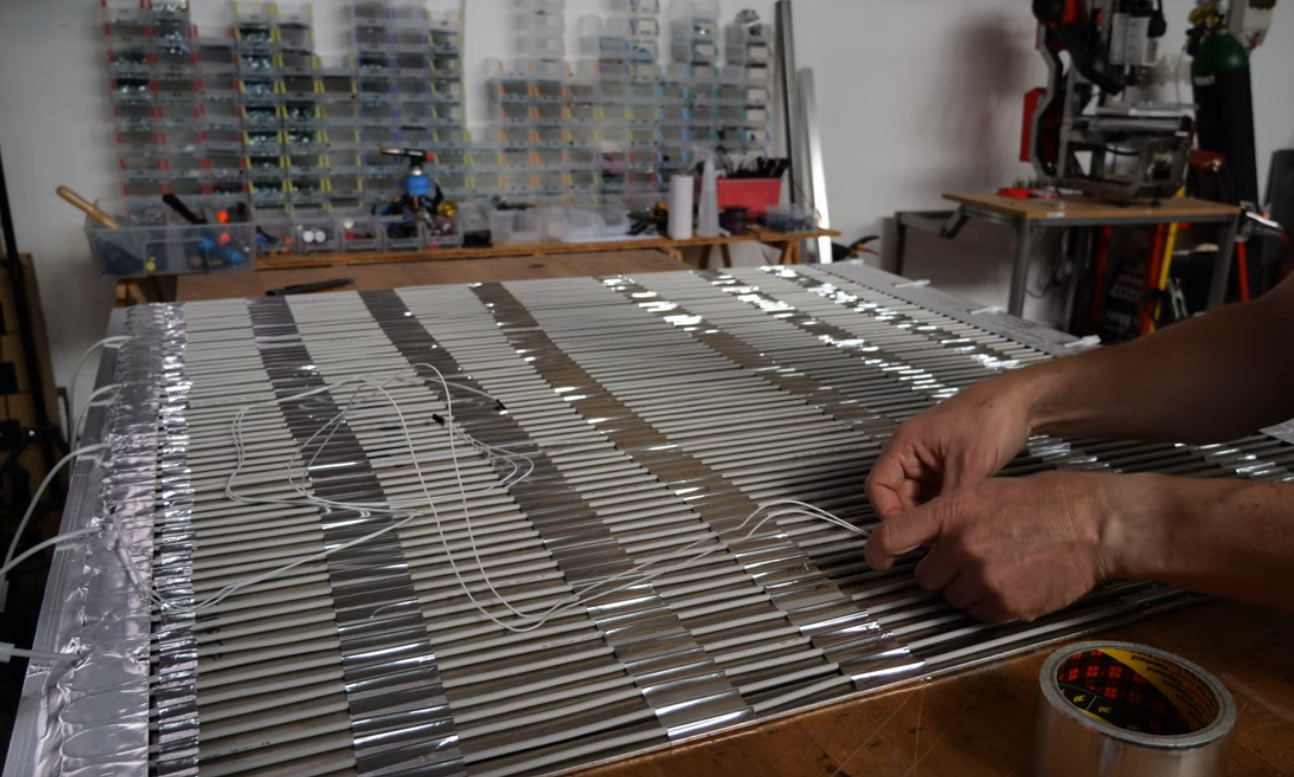

Another massive 3D printer challenge the YouTuber highlights in his video is the task of preparing a heated printing bed for this device. Heated beds help the many print materials to stick while the printer completes the job. He found the best solution was again unusual, deciding to use domestic underfloor heating cables for the bed. These would warm up the irregular sized metal bed enough to ensure that the output from his FDM printer adhered to the print bed and resisted curling at the edges.

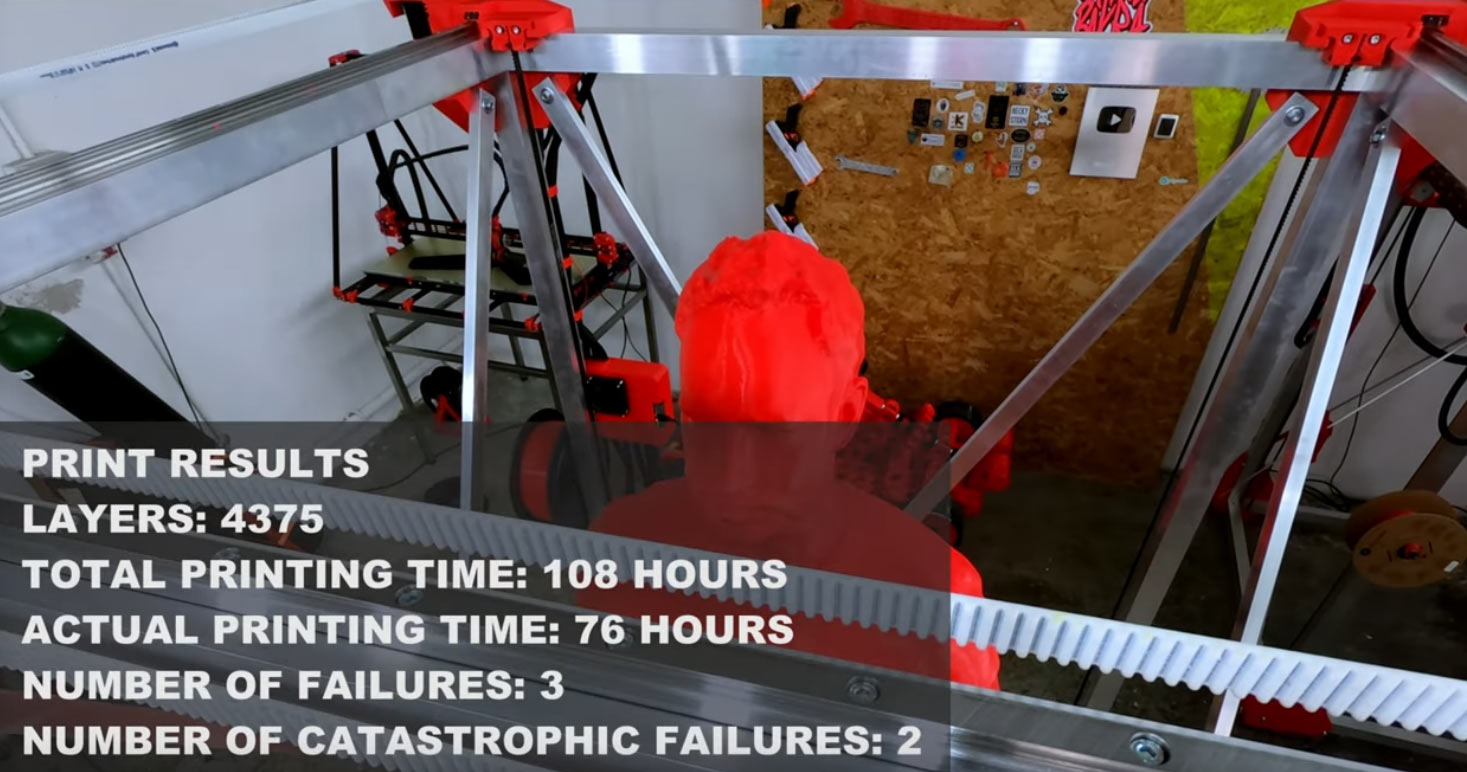

On its maiden print run, Miranda used a 4mm layer height, a 1mm nozzle, zero infill, three walls, and variable speed. The printer filament chosen was red PLA.

The next segment of the video (from about 14m and 15s) allows you to watch the red plastic Ivan Miranda clone being formed, from the feet up. Naturally this part of the video was sped up, as the actual 3D printing process for the human-scale individual in this demo took 108 hours. That time includes a number of interruptions and failures, with the successful full print taking 76 in actual printing hours. It also turns out that the finished red plastic Ivan is made up of 4,375 layers.

If you are inspired by Miranda's project, you might like to know that he sells the design files for $30. Before all the extraordinary building of this human-scale 3D printer began, he started with a relatively modest off-the shelf device.

While it is great to see makers pushing the capabilities and possibilities of 3D printing, we all need to start somewhere. To take a look at our recommended 3D printing starting points over a range of prices and requirements, check out our Best 3D Printers 2023 feature article.