For several years now, micro-LED has been touted as the next big thing in TV tech (and screen tech in general). Micro-LED tech works like the best OLED TVs in that each pixel emits its own light, meaning you get pixel-precise contrast with infinitely deep black tones – however, the pixels can be far brighter than may ever be possible with OLED, and they should be more durable and longer-lasting.

But despite being first introduced for TVs several years ago, there hasn't been a ton of movement in micro-LED TVs. They're extremely expensive, and they're generally only available in very large sizes, mostly breaking way past the 100-inch battery (though Samsung managed to get the tech into a 75-inch set). And these huge sets are still 4K, when you might expect the likes of Samsung to make them 8K.

So why hasn't more progress been made, and will this change soon? I've already heard from one big manufacturer of the tech that it's between five and 10 years away from being remotely mainstream, so at a recent Hisense event to highlight the company's also huge (but much less expensive than micro-LED) laser TVs (which combine ultra short throw projection tech with a specially matched light-rejection screen), I spoke to Dr. Liu Xianrong, Chief Scientist and General Manager of Hisense Laser Display, about the future of giant screens.

He explained that the problem with micro-LED, similar to OLED TVs, is that they have some fixed costs and complexity in their production process that aren't really reduced by making the sets smaller, and there isn't an obvious way to change the cost and complexity on the horizon – so the economics of building micro-LED screens may not be able to bring it to the mainstream any time soon.

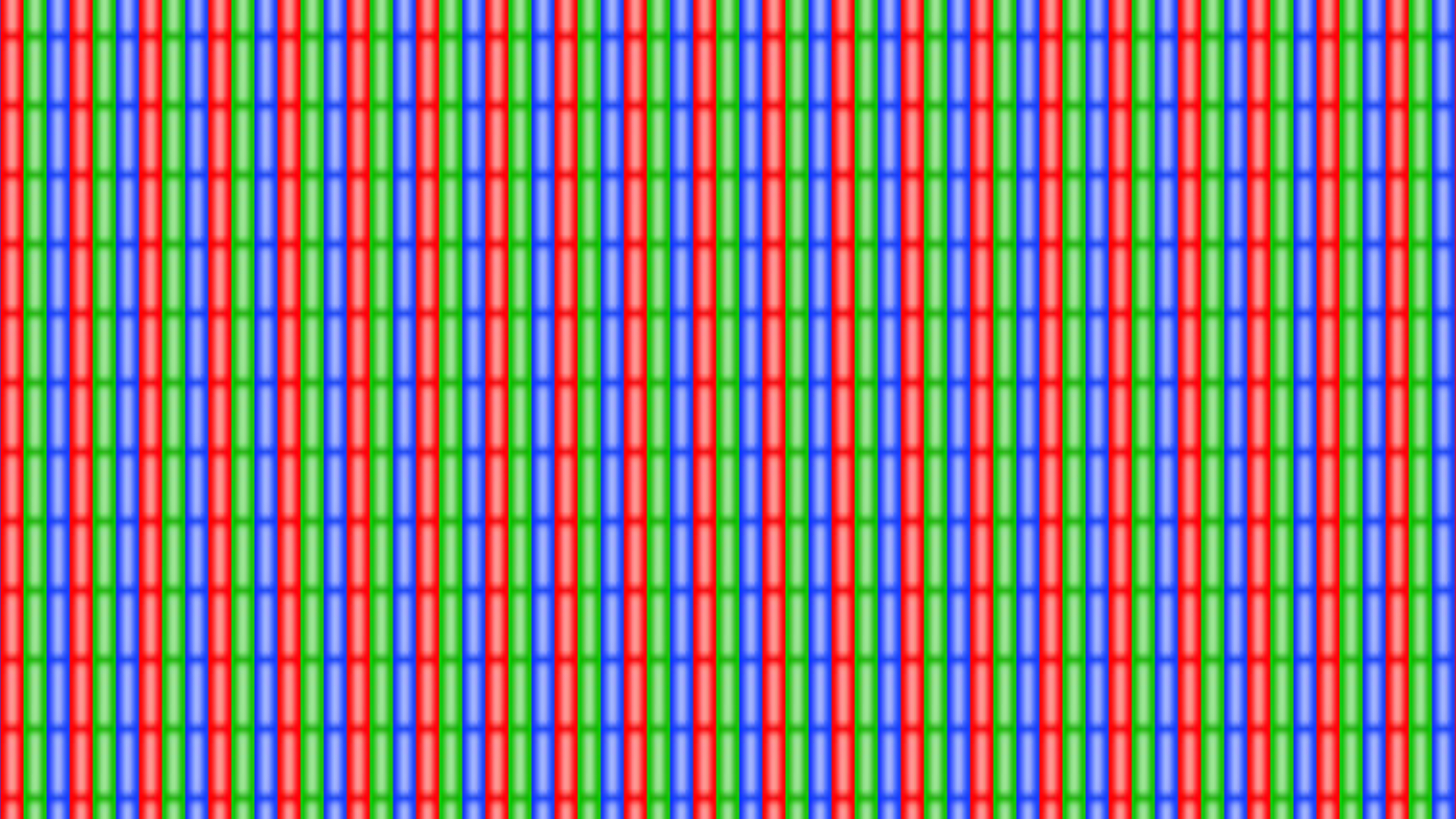

Dr Liu explained that the problem in the case of micro-LED TVs is that each pixel is made of three sub-pixels (red, green and blue) and that these pixels are created by different companies, and have to be brought together and then combined when manufacturing the panel.

The OLED equivalent to this could be considered to be the masking process, which again requires material from different places to be deposited using an elaborate and pricey system, which hasn't changed much since the tech launched, hence why the price has stayed high. Inkjet-printed OLED is supposed to be the solution to this in OLED's case, but we've been promised that tech is just around the corner for a long time (though TCL CSOT, the screen manufacturing and development arm of TCL, says it really is rolling this tech out now for smaller screens).

Amusingly, it's possible to make very small micro-LED screens with extremely high pixel density – think something designed for the best smartwatches – as well as very large micro-LED screens, but getting something made in the middle is where it falls apart, but that's what we really need for most TVs.

Separation of powers

Dr Liu said there's another complication with micro-LED TVs in development, though, that stems from the fact that the pixels do all the work for both the brightness and the color. When you want to make a processing adjustment to the brightness, you can't help but affect the color, and vice versa. It makes the whole panel extremely complicated to keep looking perfect, again affecting how costly the whole system is to develop and produce.

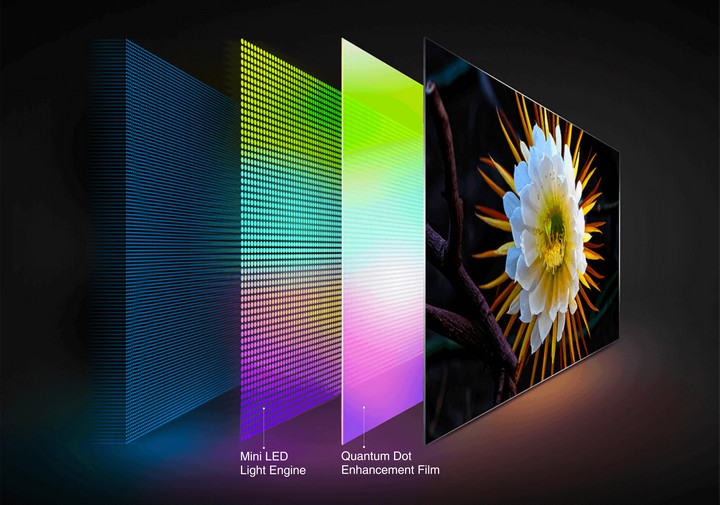

In most TV tech, including mini-LED, laser TV and OLED when used on TVs, there are separate elements that can help mitigate this. Mini-LED uses a web of tiny LED lights to generate the brightness, behind a color-changing array of pixels (generally using quantum dots). You can control these elements individually to compensate for any changes you've made to the other one and keep things consistent. QD-OLED is similar, in that a layer of blue/green OLED pixels sits behind a quantum dot color-filter layer.

And while laser TVs handle color and brightness all in one from the projector, the screen is an element that can be developed separately to help improve brightness, say – Hisense packs an ambient light-rejecting screen with its laser TVs that can roughly double brightness compared to a basic screen – so you can still use the fact that they're separate to help with refining the picture.

Packing everything into a set of RGB sub-pixels for micro-LED adds complexity that definitely can be overcome (OLED phone screens use an RGB sub-pixel structure), but again it just factors into why the TVs are likely to remain expensive, and why it will be slow for that to change.

Micro-LED and mini-LED were actually introduced to the world at the same time – Samsung announced its first mini-LED and micro-LED TVs at the exact same event. But the best mini-LED TVs have dropped rapidly in price so that instead of being in elite TVs only, the tech is now available in really good cheap sets, such as the Hisense U6N and TCL C805 (UK and Europe only).

Micro-LED seems like it's a long way from having that same breakthrough affordable moment, even though giant TVs are becoming more and more popular, which should be ideal for it. It probably is still the next big thing in TVs; just don't expect 'next' to be just around the corner.