Micro OLED suddenly became a major tech buzzword as soon as Apple announced the Vision Pro at WWDC. The mixed reality and VR headset features two Micro OLED displays — giving each eye a display with greater resolution than a 4K TV in a surface area the size of a postage stamp.

But what actually is Micro OLED technology? And how does it differ from microLED? Is one better than the other? What are the advantages and disadvantages of Micro OLED? Can you only use it with certain display sizes?

Well, let’s answer all those questions and more below. Here’s everything you need to know about Micro OLED displays.

What is Micro OLED?

Before getting into what Micro OLED is, let’s do a quick refresher on OLED technology.

OLED stands for organic light-emitting diode. It uses organic compounds, typically carbon-based, to create colors that light up when the compound gets an electrical charge. The benefit of this is that OLED pixels can turn completely off, allowing for the truest blacks and best color representation of any display technology.

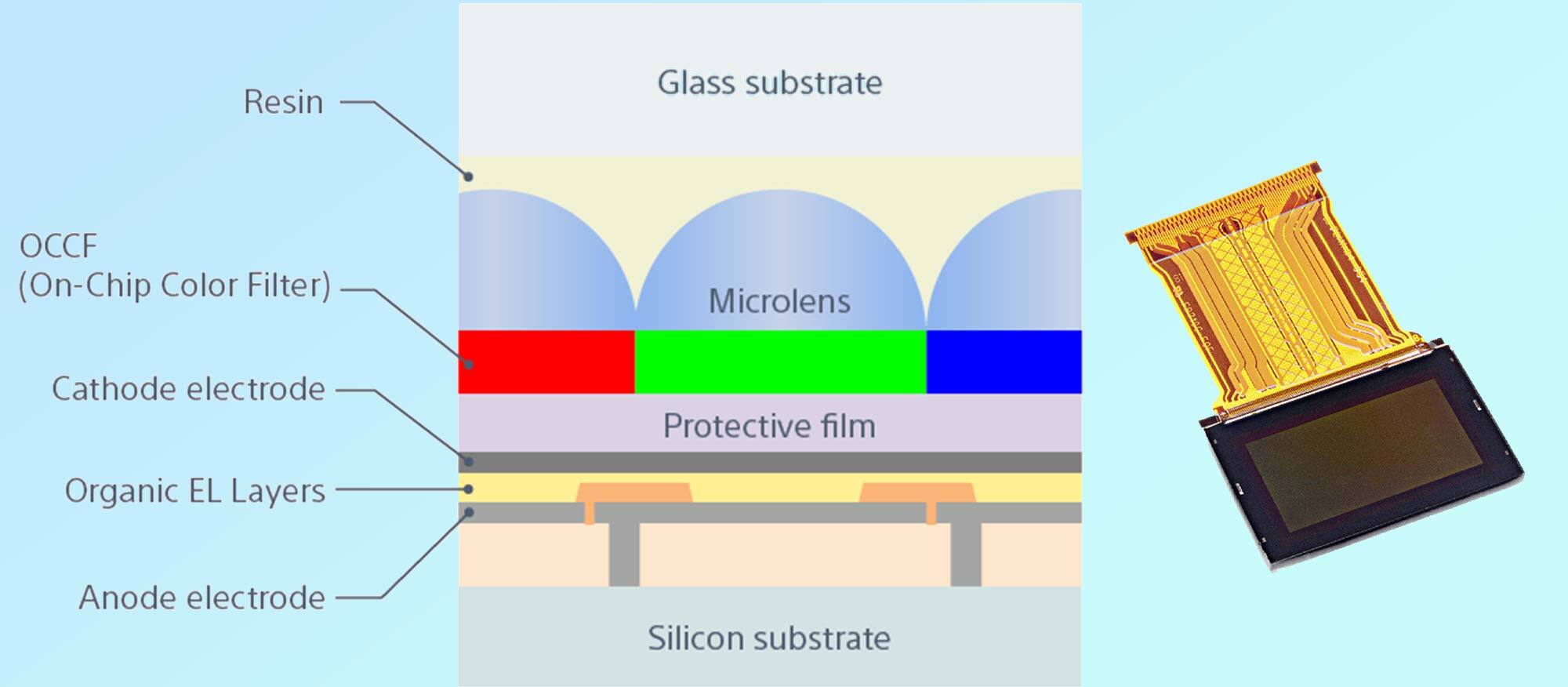

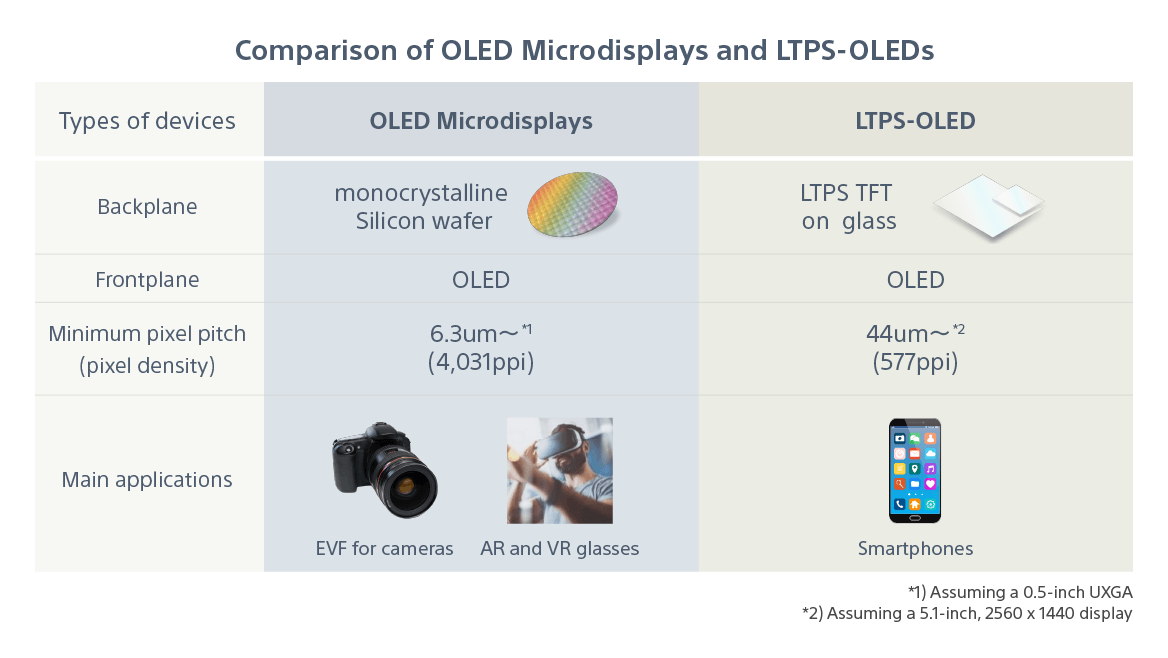

Micro OLED takes this technology and supercharges it. The tech is also sometimes referred to as OLED on Silicon (OLEDoS) and that’s because instead of placing these OLED pixels on low-temperature polycrystalline silicon glass, instead they are placed onto silicon wafers.

Advantages of Micro OLED technology

The biggest advantage of Micro OLED is that it allows manufacturers to fit exponentially more pixels into a smaller space. According to Sony, the primary manufacturer of Micro OLED displays, the minimum pixel pitch — a.k.a. the minimum distance between pixels on a display — is just 6.3 micrometers. That allows Micro OLED displays to manage a pixel density of 4,031 pixels per inch (ppi) on a 0.5-inch display.

Micro OLED displays can achieve a pixel density over seven times what traditional OLED can manage.

Compared to traditional OLED on glass, which on a typical smartphone requires a minimum pixel pitch of 44 micrometers, the difference in pixel density is massive. Those OLED displays top out at just 577ppi. That means these Micro OLED displays can achieve a pixel density over seven times what traditional OLED can manage.

Disadvantages of Micro OLED technology

So if the difference in pixel density is so massive, why wouldn’t everything transition to Micro OLED displays?

In short, production limits. Each Micro OLED silicon wafer needs to be produced and this is currently a massive supply chain bottleneck. In a previous article we did on Micro OLED in TV displays, we highlighted that the company SK Hynix produces only 100,000 12-inch wafers a month and allows 30,000 to be used for Micro OLED displays. Your average TV now is anywhere from 55-inch to 85-inch in size, so TV manufacturers would quickly burn through these wafers.

Additionally, there is an opportunity cost involved as well. Pixel density has diminishing returns the further away from the display you are. That’s why if you’re shopping for an 8K TV, you need to have a space in your home where you can get close enough to the TV to enjoy your improved resolution. So for larger displays like TVs, it’s not worth prioritizing the Micro OLED wafers for use in these displays compared to smaller displays that are closer to your eye — like the electronic viewfinder in a camera or a VR headset.

What tech currently uses Micro OLED displays?

Based on the advantages and disadvantages we just covered, it probably won’t shock you that Micro OLED is being reserved for the smallest displays. In the case of Sony’s Micro OLED displays, it says that its displays are currently being used in electronic viewfinders for cameras and scopes, as well as various headsets, including AR and VR headsets.

The Vision Pro's Micro OLED displays deliver 23 million pixels, which is 64 times the pixel density of the iPhone’s display.

But at this point, the Apple Vision Pro is probably the most talked about piece of technology using a Micro OLED display — no offense to the Xiaomi Wireless AR Glass Discovery Edition.

And the Vision Pro features not one of these Micro OLED displays, but two of them. Each one features a display resolution “greater than a 4K TV” in a display the size of a postage stamp. Combined, the displays manage 23 million pixels, which Apple says is 64 times the pixel density of the iPhone’s display. While future Micro OLED devices are surely in the works — the long-rumored Apple Glasses are currently tipped to use Micro OLED displays — the Vision Pro really puts in perspective why it's so effective for smaller displays.

Unfortunately, it also further highlights the supply chain constraints caused by the silicon wafers. Some reports suggest that Sony can only produce 100,000 to 200,000 Micro OLED displays per quarter. So while the results of Micro OLED are certainly impressive, we still have a long way to go before it becomes the standard display technology, if that ever happens.

Micro OLED vs MicroLED

Note that Micro OLED and MicroLED are not the same thing. While they have incredibly similar names and are relatively new, the technology behind the two types of displays is notably different.

The biggest difference? MicroLED ditches the organic compounds found in Micro OLED displays. This could allow them to be cheaper to produce than Micro OLED displays and possibly with a brighter, more power-efficient picture. This makes them ideal for smartphones and smartwatches, though like with Micro OLED trying to eventually put MicroLED into a TV isn’t off the table if the shortcomings of the production process are worked out.

And there are shortcomings. The MicroLED process is not easy according to Ray Soneira, president of DisplayMate Technologies. "MicroLEDs are literally tiny LEDs that are made one at a time, and then packed and assembled into a display using robots that pick and place them one at a time, first into smaller substrates, and then the substrates are assembled onto the final display." If even just one of those LEDs misses the mark, the entire display is compromised.

Still, many are working on making MicroLED more prevalent, including Apple. Apple is reportedly working on MicroLED for use in both the iPhone and the Apple Watch, with a MicroLED Apple Watch Ultra rumored to arrive in 2025.

So if you need to remember the differences between these “Micro” display technologies, if it's in a mixed reality or VR headset, it’s probably using Micro OLED, which are organic light emitting diodes on a silicon wafer. If the device is a smartphone or smartwatch, it’s probably MicroLED, which places individual pixels onto tiny sheets that are then assembled into a larger display.