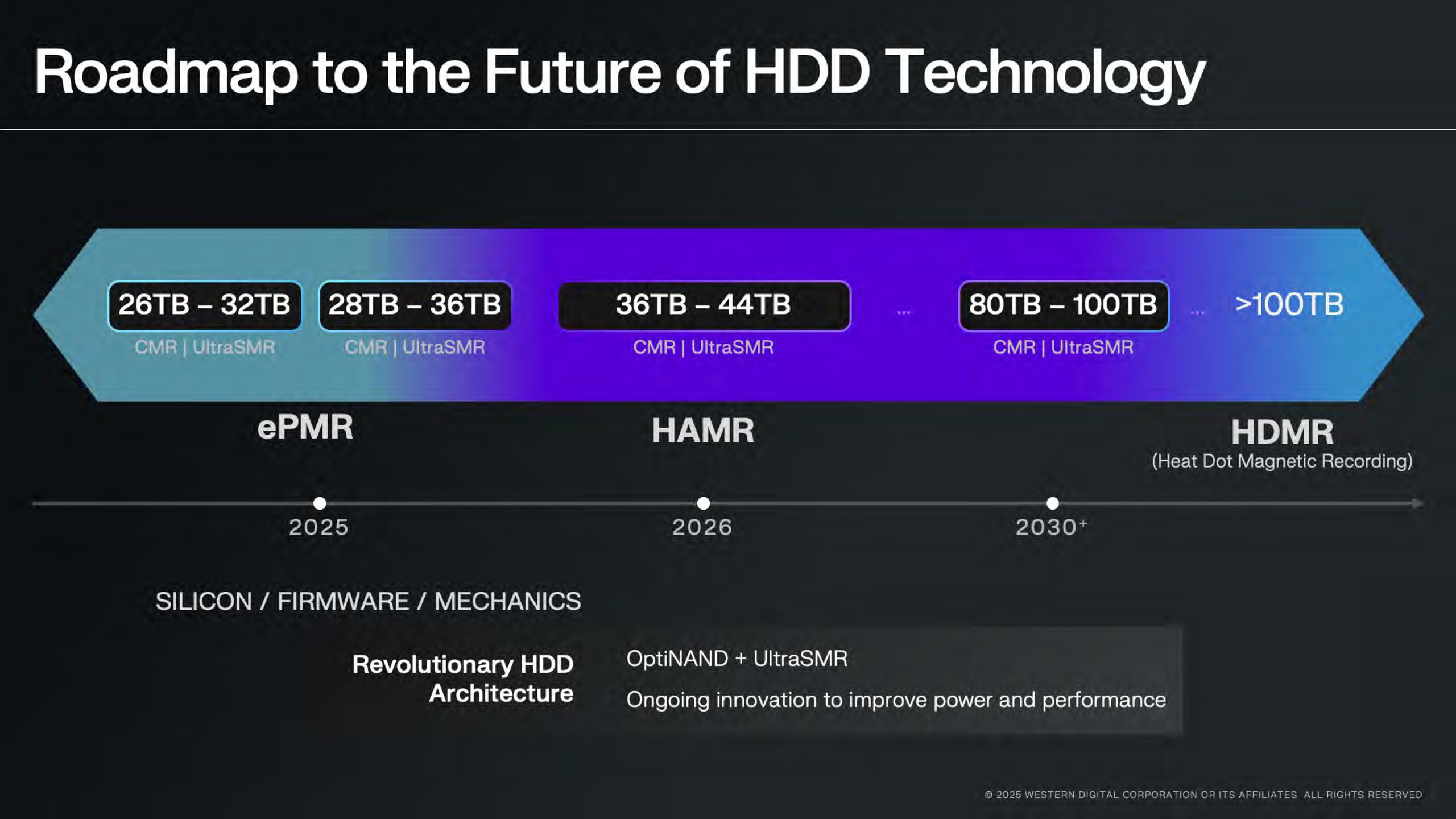

Western Digital is set to introduce its first hard drives featuring heat-assisted magnetic recording (HAMR) technology, and around 2030, this technology will enable the company to build 80TB–100TB HDDs. At that point, FePt-based granular media will start reaching its limits in terms of areal density. But Western Digital is already working on the next step for its hard drives: heat dot magnetic recording (HDMR) technology.

The HDMR is a next-generation recording technology that involves heat-assisted writing and bit-patterned media (BPM) that promises to achieve areal densities of around 8 Tb/inch^2 and beyond (according to Seagate) and to enable 10-platter HDDs with capacities of 120TB or higher. This technology is projected to be quite expensive as bit-patterned disks must be physically patterned using lithography or etching equipment in cleanrooms. Let us talk about this development in more detail.

All modern HDDs use platters featuring a granular magnetic coating. In such media, grains vary slightly in size, shape, and exact positioning, which introduces noise and interference and limits how tightly bits (and tracks) can be packed. To read tracks reliably, HDD makers use specially designed two-dimensional (2D) read heads, which consist of two read heads. Disks used in Western Digital’s 10-platter 24TB HDDs with conventional magnetic recording and ePMR 2 feature an areal density of around 1.2 Tb/inch^2. Seagate’s 10-platter 30TB hard drive, which uses HAMR and FePt media, has an areal density of around 1.5 Tb/inch^2. Seagate believes that granular FePt (or other high-anisotropy media) will enable the industry to achieve areal densities of 4 Tb/inch^2 or possibly even 6 Tb/inch^2.

At around 5 Tb/inch^2, it will become harder not only to read granular media reliably but also to write to it, which will push the industry to move on to ordered-granular (OG) media that incorporates patterning in one dimension (according to Seagate). OG media is expected to feature grains of uniform size, placed at precise, repeatable intervals. This allows the write head to form data bits with tighter boundaries and less noise. OG media will require new magnetic coatings, but its benefits will be significant—with uniform grains, magnetic properties become more predictable, reducing variations in write/read performance.

However, ordered-granular media is expected to support areal densities of up to approximately 7 Tb/inch^2. To reach 8 Tb/inch^2, bit-patterned media—which physically carves the disk into isolated bits using lithography or other processes—will be needed. BPM represents a more radical shift in manufacturing and entails significant production costs.

Combining the physical isolation of bits (from BPM) with energy-assisted writing (from HAMR) in HDMR can push areal densities far beyond what either approach alone can achieve. This may explain why Seagate does not reveal its areal density expectations for this technology. However, BPM requires a complex patterning process (e.g., nanoimprint lithography, e-beam lithography, or highly sophisticated etching), which is expensive. Additionally, local heating must be extremely precise — too much heat affects adjacent dots, while too little results in write failures — so new types of lasers will need to be developed.

Given all the complexities associated with HDMR, this technology will not come to the market anytime soon. Western Digital expects it to arrive sometime in the next decade, at which point it will enable HDDs with capacities well over 100TB. Interestingly, the latest iteration of Western Digital's roadmap no longer mentions ordered-granular media, unlike its 2022 version. It is possible that this time, the company intends to move directly to the technology that delivers the best results.