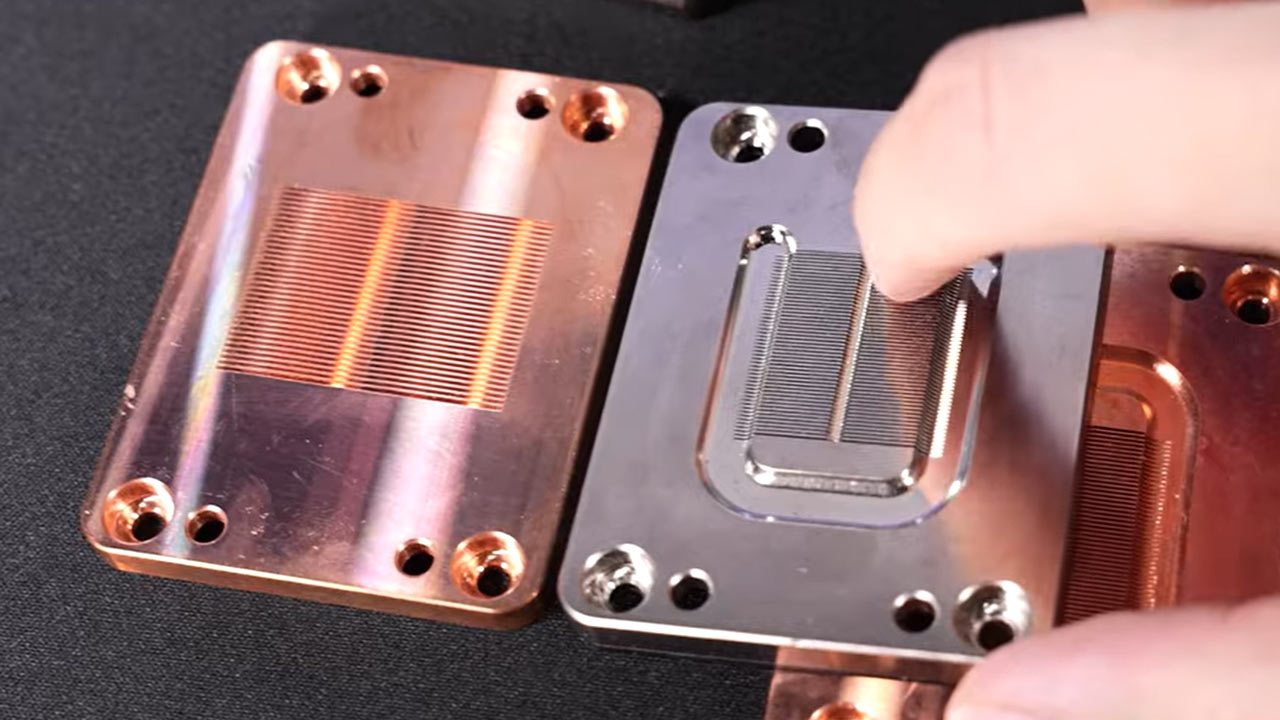

A new video discusses changes made to the Thermal Grizzly Mycro Direct Die water block so that it could be marketed to enthusiasts once again. Necessary changes have now been implemented alongside several design enhancements to precipitate the launch of the new Mycro Direct Die RGB Pro, which we highlighted earlier in the week. In brief, the design has seen improvements in machining, increased surface area, and better nickel plating to get it to where it is now – boasting six degrees Celsius better temperatures than its issue-prone predecessor could achieve (when it worked), and it now comes with added RGB LEDs…

Back in May, we reported on the seriously underperforming Intel LGA1700 compatible High Performance Heatspreader (HPHS) V1 and Intel Mycro Direct Die V1 units from Thermal Grizzly (TG). Expert overclocker Der8auer, who is also the TG CEO, published a new video explaining that the aforementioned specialist direct-die cooling products had been withdrawn from sale after the firm “messed up.” Selling a device that sometimes delivered even worse results than a stock processor wasn't to be tolerated by the company.

The direct die cooling product should have delivered temperatures that were about 15 degrees Celsius cooler, but feedback from early adopters showed some experienced serious problems with the product. To its credit, TG took the products off the market immediately, with apologies (and accompanying video). We were told the product would be back, pending investigations, and that's what happened today

In the new video we hear that despite TG’s precise machining and attention to the finest details, some error(s) slipped through into the original devices. The investigative journey taken means that not only were the error(s) corrected, the new Mycro Direct Die RGB Pro can also deliver worthwhile improvements.

One of the changes in new prototypes was the provision of extra space machined away for the plastic around the socket. This was done to provide more consistent mounting pressure on a variety of delidded Intel processor-based systems, explains Der8auer.

However, during re-designed heatsink block testing Der8auer was alarmed that three of his delidded CPUs died after just 10-20 mount/unmount tests each. “That is not normal,” asserted the seasoned overclocker, who has experience with a wide range of models and brands in the direct die cooling gear business.

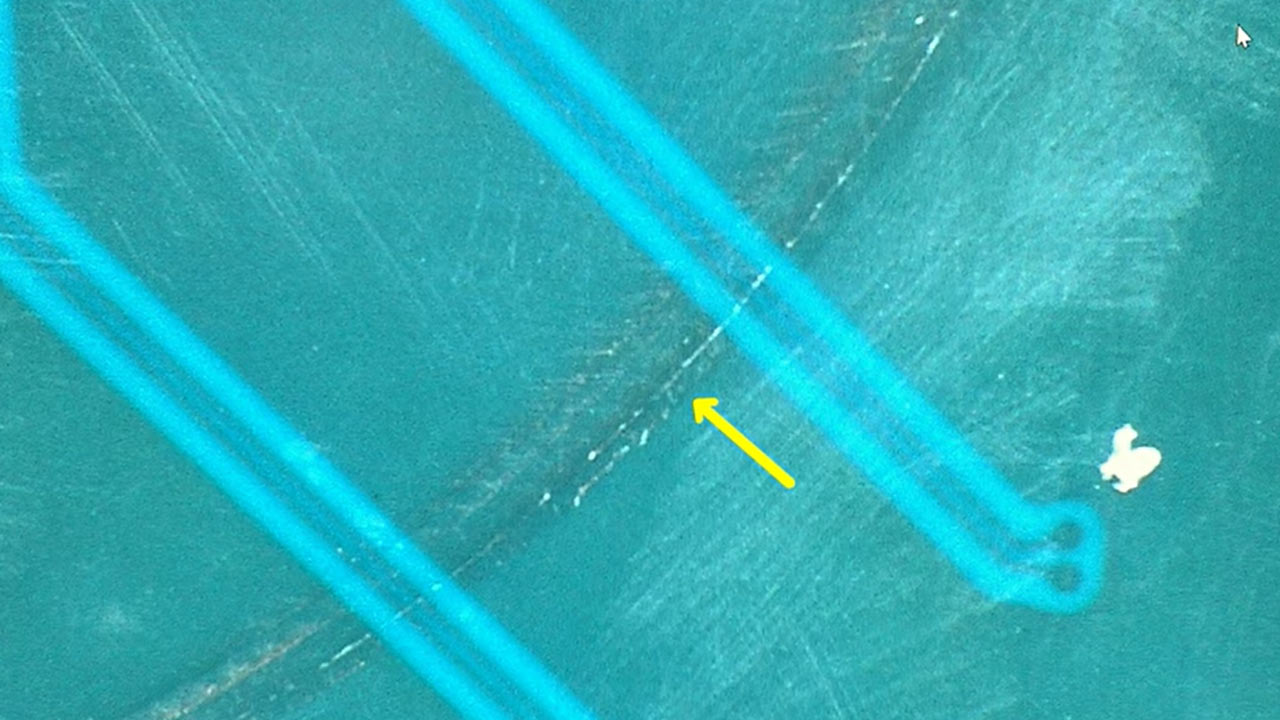

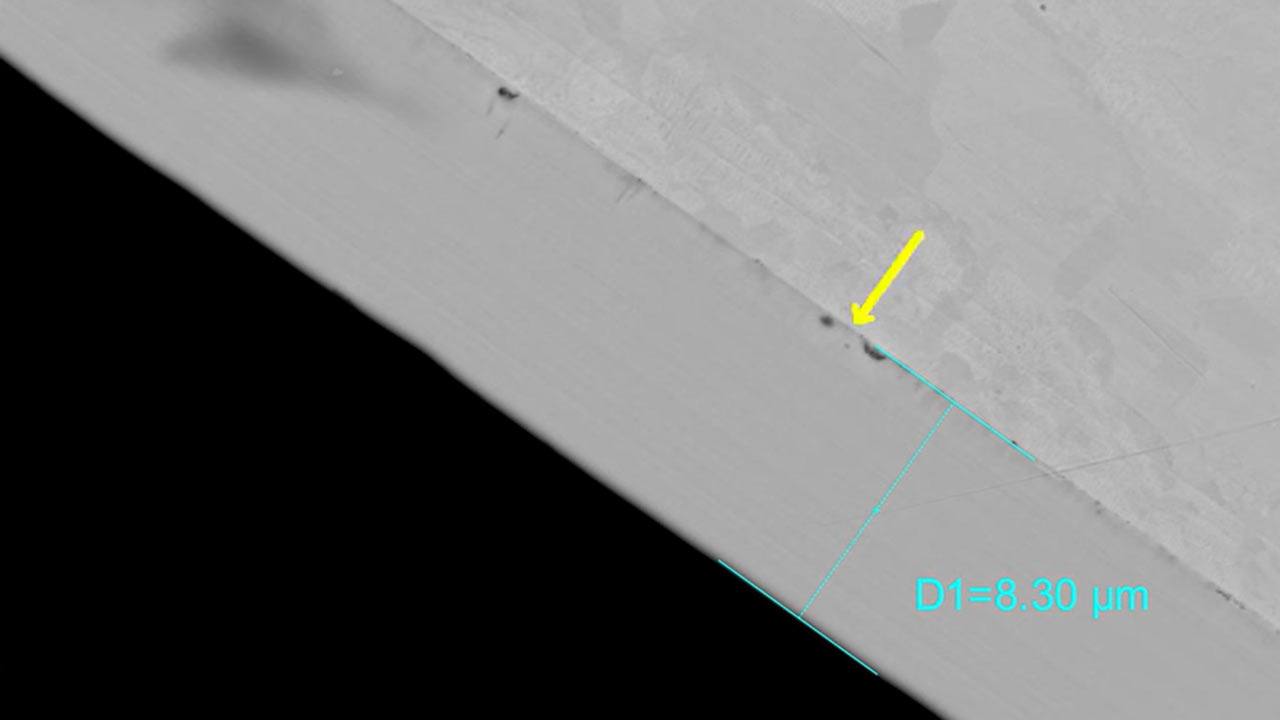

An LMX visual system was used to exaggerate the surface of the failed processor(s), and highlight issues the pressure of the direct die cooler on the processor might have caused. Der8auer saw a problem with the CNC milling-produced defined edge damaging the CPU PCB over time. Though the tool makers had previously used a 45-degree bevel to reduce any sharp edge pressure, this wasn’t enough. It was decided that the move to a rounded profile was necessary, applied where cooling block surfaces touch the processor PCB.

After that excursion, Der8auer refocused on the issue of thermals – the issue that had caused the original Mycro Direct Die to be withdrawn from sale. A new nickel plating contractor was sought, but the initial results were poor. However, the OC expert reasoned that this plating remained necessary due to direct die proponents favoring ‘liquid metal’ thermal interface material (TIM). Galium, present in ‘liquid metal’ TIM can degrade copper, or quickly destroy aluminum structures.

After contacts, conversations, and negotiations with around 20 nickel plating companies, Der8auer whittled the options down to five and ended up with one. Prototypes also varied between using chemically deposited or electroplated nickel on the copper.

The newly finalized Mycro Direct Die RGB Pro design, with nickel plating from the favored supplier, doesn’t look as ‘polished’ as some but it actually performs the best in this direct die cooling application, explained the TG boss. Electroplating nickel coating tech was chosen for better thermals, but admittedly poorer corrosion resistance.

During the last few months, since the withdrawal of the earlier direct-die liquid cooling accessory, the design has also moved from 0.5 to 0.25mm fin slots on the copper block – providing increased cooling surface area. There are more, shorter fins for higher flow rate too, delivering better performance in tests.

Before the general release of the new Mycro Direct Die RGB Pro the product has been double-checked with 10 community enthusiasts for extensive testing and is at last living up to its potential. Der8auer now admits that TG is late to Socket LGA 1700 “but it’s never too late to learn” – wise words. Lastly, the TG CEO confirmed that all the tweaks and improvements devised during the ironing out of the unfortunate direct-die thermal issues will be carried over to next-gen Arrow Lake cooling products.