There’s a big push to have iPhones built in America. And on paper it could create lots of jobs, from the final assembly of the phones to building the factories that will be needed to get those iPhones put together.

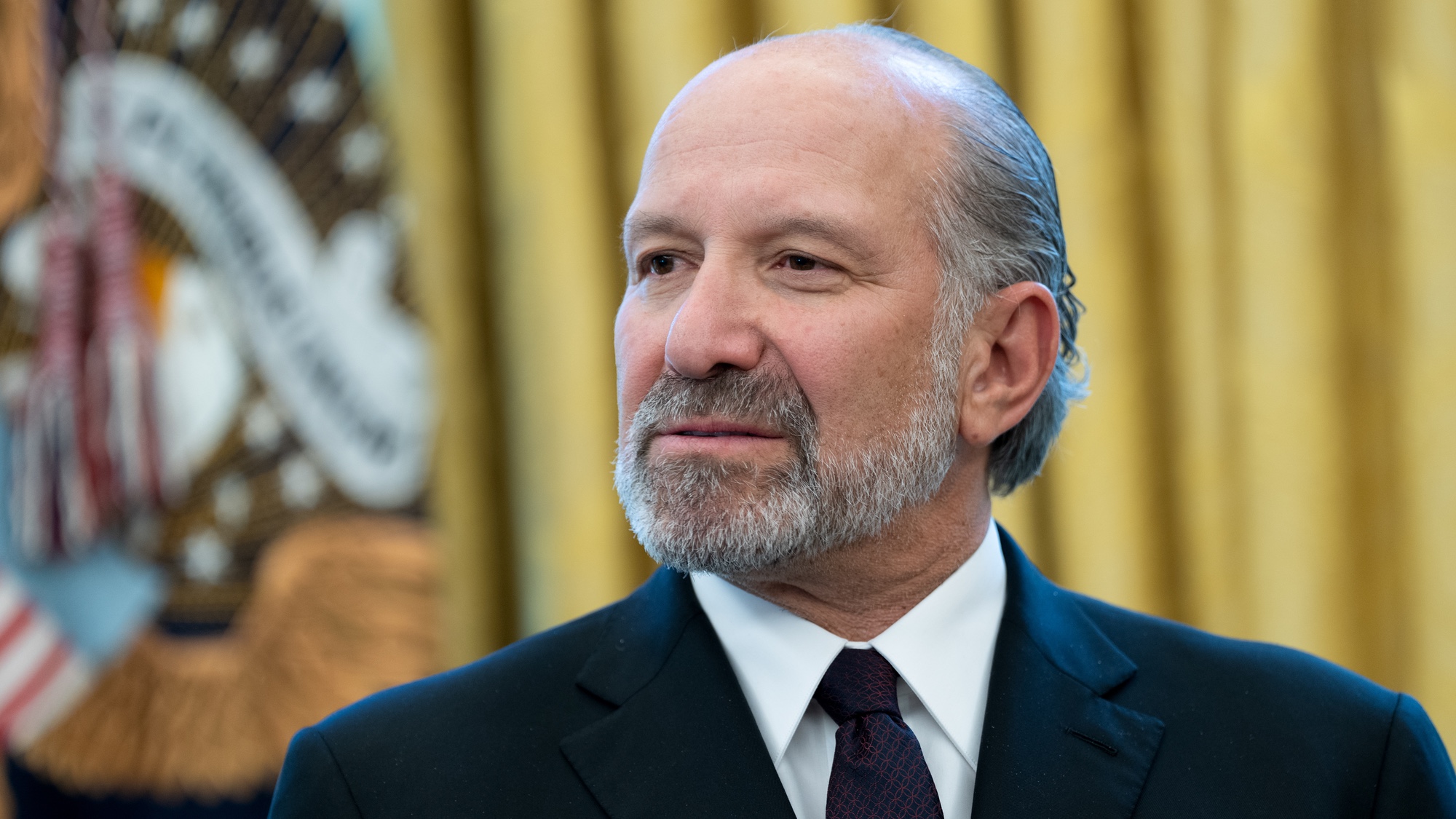

Howard Lutnick, the U.S. Secretary of Commerce, appeared on the "Face the Nation" program on CBS News earlier this month to defend the Trump tariffs that have been reverberating through the global economy.

During that interview, the commerce secretary spelled out a vision that included creating jobs for U.S. workers by taking the electronics manufacturing handled in other parts of the world — by and large, we're talking about China — and bringing that back to the U.S.

As Lutnick explained on the April 6 broadcast, the key will be automated factories. "Who's going to build the factories? Who's going to operate the factories? Who's going to make them work? Great American workers," he said.

"You know, we are going to replace ... the armies of millions of people screwing in little screws to make iPhones, that kind of thing is going to come to America," he added.

A promise to bring back electronics manufacturing jobs from overseas — a process known as "reshoring" — has been bandied about by President Donald Trump dating back to his first term, and Lutnick's description is just the latest iteration of that pledge. To some, it's an appealing idea that's one of the cornerstones of the Trump administration's economic goals.

It's also very unlikely to happen, and certainly not any time soon. Here's why.

What's Apple's stance on making iPhones in the U.S.?

If Apple has bought into Lutnick's vision of U.S. based factories using automation to "screw in little screws to make iPhones," the company is keeping that to itself. I reached out to Apple to ask if the company has been in talks with the Trump administration on the prospect of producing iPhones stateside, but haven't heard back with a comment.

To be fair to Apple, though, the company has let its money do some talking when it comes to some manufacturing initiatives.

Back in February, the company announced it would spend more than $500 billion over the next four years to expand its U.S. operations. Included in those plans will be a facility in Houston where Apple will build servers for its Apple Intelligence efforts, along with other efforts aimed at bolstering manufacturing.

That new investment builds on some commitments Apple has previously made, such as an Austin, Texas-based campus where the company makes Mac Pros.

So yes, Apple does build products in the U.S., with plans to build even more. But a keen eye will detect that servers and Mac Pros aren't exactly the same thing as iPhones.

"[Apple] is able to [build some Macs in the U.S.] because these are sold in the thousands or tens of thousands, not millions or tens of millions," said Techsponential lead analyst Avi Greengart, when I asked him to explain why Apple builds some products domestically but not others. "The tooling and tolerances of a desktop computer are also much more forgiving than smartphones."

There's also the matter of cost, with the Mac Pro starting at $6,999. That's a bit steeper than the $599 Apple charges for its least expensive phone, the iPhone 16e.

"The dollar amounts involved are higher [with the Mac Pro], masking the higher labor costs involved in setting up shop in the U.S," Greengart added.

Other iPhone manufacturing roadblocks

So that may explain iPhones aren't currently being built in the U.S. What's standing in the way of that production moving to these shores?

Let's start with labor costs, with a big reason for production moving offshore being that workers earn lower wages in other markets. Even now, as IDC group vice president of worldwide device trackers Ryan Reith pointed out to my colleague Tom Pritchard for an article on the impact of the Trump tariffs on phones, more production is shifting to countries like India and Indonesia to deal with rising labor costs in China.

In other words, forget about phone assembly jobs coming to America, where workers earn even more. That's why Lutnick's comments to CBS centered around automated factories.

“There's no way it would ever make sense, nor could it happen in my opinion, to have the complete end-to-end [manufacturing] solution done in the U.S."

— Ryan Reith, IDC

But phone production also happens to be centered overseas because that's where the parts that make up phones are assembled, too. There's an oft-told story about Apple switching the display on the original iPhone to glass in the six-month period between the phone's unveiling and its June 2007 launch.

A number of lucky breaks made that last-minute change possible, but a big reason was that iPhone supplier Foxconn had the factory space to quickly turn around that order. That likely doesn't happen if production gets reshored.

"Phones have parts from South Korea, Taiwan, China, the U.S., Japan, and more, and are dependent on critical inputs from an even longer list of places," Greengart said.

The most likely scenario for iPhone assembly to be handled stateside would be for final assembly only to be handled in the U.S. “There's no way it would ever make sense, nor could it happen in my opinion, to have the complete end-to-end solution done in the U.S.," IDC's Reith said. " It just doesn't make sense."

But even focusing solely on final assembly would require a ramp-up effort to build factories and equip them with the necessary tools to put the finishing touches on smartphones.

Reith estimates that it would be three years before small-scale production would be ready to go online, with mass production not ready for five years — and he described that timing to Tom's Guide as a best-case scenario.

"It would be enormously expensive to build from scratch, labor costs would be higher, education in engineering and machine tooling would need to be created, immigration would need to be expanded, and the whole process would require massive automation," Greengart said. "At the end of that process, you might still end up with more expensive products, but they’d be mostly sourced and entirely built in the U.S."

iPhone production outlook

How much more would an iPhone made in the U.S. cost? Prior to the Trump administration scaling back some tariffs while temporarily exempting smartphones from the higher rates, Dan Ives, global head of technology research at financial services firm Wedbush Securities, went on CNN and claimed that a U.S.-built iPhone would cost $3,500.

Even if that number seems fanciful, his assessment that a U.S.-built iPhone is a "fictional tale" seems like a reasonable claim, given what we know about all the obstacles standing in the way of that happening.

As Greengart put it when talking tariffs with my colleague Tom Pritchard, there's business and political advantages to reshoring some manufacturing. "However, the current incentives, costs, and shifting regulatory environment do not encourage investing towards this outcome," he added.

That certainly seems to be the case from my research into phone manufacturing.