Announcing the $368 billion AUKUS deal in San Diego last week, Prime Minister Anthony Albanese framed it as an industry policy.

“Just as the vision of my predecessors, Curtin and Chifley, in creating our automotive industry, lifted up our entire manufacturing sector, this investment will be a catalyst for innovation and research breakthroughs that will reverberate right throughout the Australian economy.”

That’s no doubt true, just as it’s also true that Australia’s manufacturing sector was built on a foundation of making cars, specifically Holdens and Falcons, and later, Camrys.

Now, thanks to AUKUS, Australia’s manufacturing will be built on a foundation of defence, specifically buying and making nuclear submarines.

But there is likely to be an opportunity cost in that. Given the amount of money involved there won’t be much, if any, left for anything else, such as the global energy transition, health care and agriculture –

the subjects of our special series on Australian innovators that begins today.

The opportunity cost of AUKUS was highlighted within just two days last week when the European Commission released its Net-Zero Industry Act and the Critical Raw Materials Act, a direct climate and investment strategy response to the massive US Inflation Reduction Act signed by President Biden last year and which includes $560 billion to be spent on clean energy industries.

Also, India has what it calls the Production-Linked Incentives scheme, and Japan has announced the Green Transformation (GX) Implementation Council, which has two pillars – more nuclear power and a carbon price.

Australia’s $3 billion over six years to support renewable manufacturing always looked small and tentative, and now it has been trumped. The $368 billion earmarked for AUKUS, along with the other pressures on the budget, will mean there will be no more money after that for this country’s intrepid renewable energy entrepreneurs.

So it’s just as well there are some good ones who are doing it anyway, without much government support. Some are even taking Australian technology to the world.

Our multicultural advantage

X2M Connect is one of them. The Melbourne-based company has invented a device that helps electricity and gas companies run their networks more efficiently and safely and has become the market leader in Korea.

Interestingly, CEO Mohan Jesudason says being Australian is an advantage in Asia because we’re such a multicultural society.

He told me: “We understand those countries very well because we’re so multicultural. In Korea, for example, there was one US competitor, and they sent the customers a gift wishing them happy Chinese New Year and wondered why the Koreans got so offended. They hadn’t worked out that they’re not Chinese!”

He says that breaking into Asian markets is not easy.

“Look, you have to do the work. You’ve got to understand your local environment. You’ve got to build the right relationships.”

Another company trying to take Australian technology to the world is Perth-based Hazer Group, which patented a process for making hydrogen from methane with a byproduct of graphite (carbon).

The company has had some problems with a demonstration plant in Perth, delaying it for about 12 months, but it’s also working on a joint venture project in Vancouver, Canada.

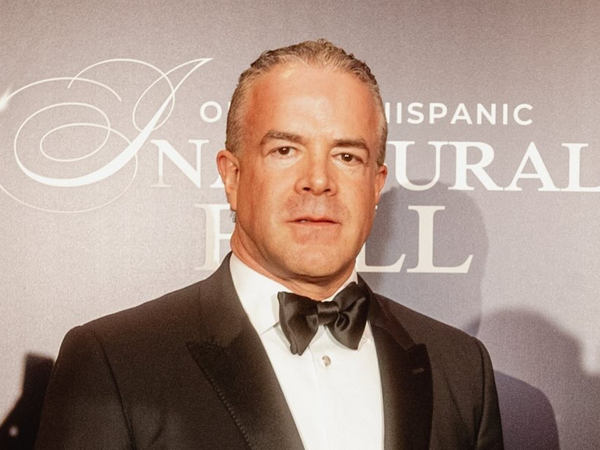

CEO Geoff Ward told me that the Hazer process produces cheaper hydrogen in places where there’s no cheap renewable electricity.

“Electrolysis works well where electricity is really cheap and low emissions, because it takes about six to seven times as much power to produce a kilogram of hydrogen by electrolysis as it does for us to produce a kilo of hydrogen from a gas feedstock,” he said.

“So, electrolysis will work in Spain, in Algeria, Mexico, maybe in bits of Texas, in the north-west of Australia, in Queensland.

“But if you’re somewhere where you have limited access to renewables … like France, Germany, the Scandinavian countries, the Netherlands, the north-east of the US, large parts of Canada, but you have access to gas, then you can make hydrogen at low emissions using pyrolysis where it’s needed and at a much lower overall energy burden because you’ve already got the gas there.”

A concrete solution

Sydney-based Calix has achieved the holy grail of a low-emissions kiln to produce cement, among other things.

The technology was originally developed in the Victorian town of Bacchus Marsh and is now being applied to “direct air capture” – that is, taking carbon dioxide out of the atmosphere, which is now seen as an essential next step in dealing with climate change.

The problem with cement manufacture is that half the weight of the limestone it is made from is made up of carbon dioxide trapped in the rock, which is released when it is roasted into cement.

Essentially, the Calix technology captures the CO2 because the heat is applied externally. CEO Phil Hodgson told me: “If you’re only heating the tube externally, then what comes out of the tube at the top, (is) pure CO2.

“That makes the capture of it much, much easier and cheaper to do than conventional methods. That’s the technology that we’re developing in Belgium with Heidelberg Cement and Cemex and these sorts of industrial players.”

And then there’s the Melbourne firm called RayGen, which is developing a remarkable technology for capturing and storing solar energy – by using mirrors to concentrate the sun’s energy, and heat differential turbines.

Energy in the air

Or the Mount Isa business called Vast Solar that is using molten salt to store energy, or the Sydney consultancy Energy Estate that’s working with a Canadian firm called Hydrostor to fill an old mine in Broken Hill with compressed air for storing energy.

In Adelaide, there’s a firm called 1414 Degrees that is melting silicon by heating it to that four-digit temperature, also as an energy storage system.

The company has been struggling with a sinking share price for a year or two, and is still burning cash, but executive chairman Kevin Moriarty told me that molten silicon will have a place in the range of storage solutions.

“The batteries have a place. If you want a quick burst of power, great, and they’re probably the most cost-effective solution. If you want seasonal storage and so on, pumped hydro works.

“… we’re not trying to compete with batteries and pumped hydro, we just think that we will be able to reduce the need for those and the market for those by dealing with the heat needs of society at the same time.”

There are quite a few more that we don’t have the space to mention today, but let’s just hope none of them needs too much money from the government … unless they can make something that goes into a submarine, of course.

Alan Kohler is founder of Eureka Report and finance presenter on ABC news. He writes twice a week for The New Daily