Again and again, Bruno Pescheux made one point to his colleagues: no one must know what their company was up to. Secrecy was paramount. In 2013 and 2014, Pescheux ran the Syrian subsidiary of Lafarge SA, the French company that was then the world’s biggest cement conglomerate. As a civil war caught and spread, the company struck a grim deal: to pay millions of dollars to Islamic State (IS), the world’s most notorious terrorist group, treating it as a strategic ally.

These payments bought IS’s blessing so that Lafarge’s factory in Syria could keep making and selling cement – even as its European executives left the country, its local employees got kidnapped, and bombs and gunfire tore up the region. Lafarge bought raw materials from IS-approved vendors, supplied IS with cement, and paid them to squeeze the competition – in this case, cement imports coming over the border from Turkey. In mob jargon, this was more than protection money; in MBA jargon, the company optimised for IS.

The managers in Lafarge’s Syrian subsidiary knew all too well what they were doing, and they tried hard to hide it. Once, while referring to vehicle passes that IS issued Lafarge’s trucks, Pescheux emailed a go-between to say that “the name of Lafarge should never appear for obvious reasons in any document of this nature. Please use the words Cement Plant if you need but never the one of Lafarge.”

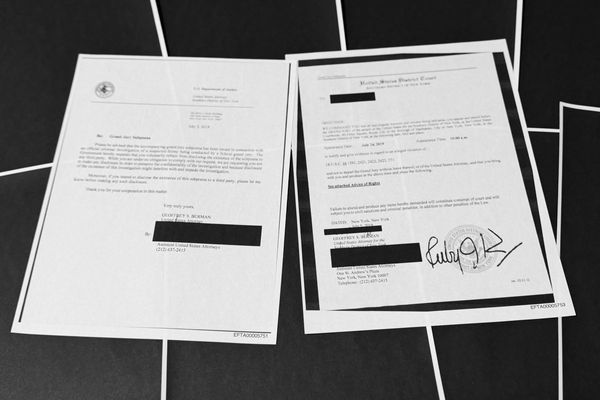

At the time, the factory, in the town of Jalabiya, was one of more than 1,600 that Lafarge ran in 61 countries. But this was no distant outpost going rogue, unnoticed by headquarters. Executives in Lafarge’s offices in Paris were complicit in the relationship with IS, as dozens of internal emails and documents show. On such evidence of wilful collaboration with IS, the US Justice Department filed criminal charges against Lafarge. (The company merged with the Swiss cement giant Holcim in the summer of 2015, not long after IS finally annexed the Jalabiya factory for itself.) Lafarge pleaded guilty to conspiring to provide material support to terrorist groups – the first successful criminal prosecution of any company on this charge in the US. In the autumn of 2022, the Justice Department fined Lafarge $778m. One prosecutor described Lafarge’s acts as a “staggering crime”.

The penalty threw open the doors to still more legal trouble. A group of more than 800 Yazidis, represented by Amal Clooney and other lawyers in the US, is suing Lafarge for its aid to IS, which murdered, kidnapped and raped thousands of members of this religious minority group in northern Iraq. Others who have suffered IS’s violence have filed separate lawsuits, including US journalists, aid workers, military service members and their families. “None of the $778m fine imposed by the Justice Department went to any of the victims,” a lawyer in one of these suits told me. “And this is a deep-pocketed defendant – not a random front company for al-Qaida.” These are civil cases, though, so even if Lafarge loses them, the consequences will be all too familiar. A corporation pays an affordable sum in damages. The court issues a stern scolding. Onward to business as usual.

But on home turf in France, Lafarge faces a criminal case that might yield a reckoning without precedent. Dozens of former Lafarge employees in Syria, along with two non-profits, Sherpa and the European Center for Constitutional and Human Rights, have accused Lafarge of complicity in crimes against humanity. The history of treating companies as actors stoking conflict for profit dates back to the Nuremberg trials, says Mark Taylor, the author of a book titled War Economies and International Law. But criminal prosecutions usually target executives, rather than the companies they run – and even then, accountability is rare. “I can only think of three businessmen who’ve been convicted over the last 20 years, for complicity in war crimes or crimes against humanity – and none before that,” Taylor told me. “And I can’t think of a single company that has ever been convicted on either of these charges.”

Multinational corporations are slippery targets in the field of war crimes. “Their conduct often takes place in the shadows, so evidence is difficult to obtain,” Clooney told me. “Sometimes it is not clear what the company knew. Or there’s no court where victims can claim their rights.” Also, as the 18th-century lawyer Edward Thurlow remarked, companies “have neither bodies to be punished, nor souls to be condemned”. What’s the corporate equivalent of putting a war criminal behind bars for life? As yet, the question has no answer.

Over the past quarter-century, though, the number of attempts to prosecute companies for war crimes or crimes against humanity has been rising, Taylor says. That’s partially a result of countries signing and ratifying the Rome Statute of the International Criminal Court (ICC), which entered into force in 2002. The statute knitted the ICC’s frameworks for these two grave crimes into countries’ criminal codes, allowing prosecutions to be launched at the national level, rather than in the rarefied halls of The Hague. But the rising number of prosecutions is also a symptom of our heavily corporatised times. Two-thirds of the wealthiest entities on the planet are not nations but companies. Their influence is everywhere – even where we don’t see it, as in the actions of governments or the machinations of terrorists.

The French case against Lafarge has been bouncing between appeals and counter-appeals since 2016, not long after its conduct was first exposed by the Syrian news outlet Zaman Al Wasl and the French newspaper Le Monde. (A Lafarge spokesperson told me: “These allegations relate to a legacy issue from a decade ago that Lafarge SA is addressing through the legal process in France and the United States.”) If a court eventually rules against Lafarge, it will be a watershed moment – a recognition of the fact that companies should be punished when they fund or support large-scale atrocities to protect their bottom lines. This happens more often than we’d think. The culprits aren’t just the obvious ones, like arms manufacturers, mercenaries for hire, or fossil fuel and mining giants. They may sell far more innocuous products – bananas, or beer, or indeed cement out of a factory in a barren corner of northern Syria.

* * *

In the scrubland of Jalabiya, the factory was the only large building for miles around. Four kilometres of boundary walls wrapped around its premises. The cement silos and the 130-metre preheating tower rose high into the sky. The pipework caught the sun and winked. At night, when all its lights were on, the factory resembled a cruise liner adrift on a flat, dark sea. In 2013 and 2014, as the civil war escalated, cement-laden trucks kept rolling out of the factory’s gates, as many as 160 a day. A war zone was a fine market for a cement company. When shelled homes need to be rebuilt, or when a terrorist group needs to construct an underground warren of tunnels, cement is the first item on the shopping list.

What would the world even be without cement – this undistinguished, death-grey powder made from crushed, superheated minerals, and pulverised so fine that a pound of it contains 150bn grains. By itself, it is dusty nothingness, but combined just so with water and sand, it becomes concrete – so strong that a concrete launch pad can bear the weight of a 2,200-tonne space shuttle. If we had no cement to turn into concrete, we’d live in a parallel, stunted version of our world. We’d still have bridges, dams and buildings, but they’d be shorter and narrower – nothing like the monumentality of the Brooklyn Bridge or the Three Gorges Dam or the Shard. We’d have no nuclear reactor stacks or multi-tiered stadiums, no dry docks or office blocks or Fort Knox. Our subways would be more rudimentary, our motorways less robust. Concrete is the foundation of almost all construction – quite literally, because building work rarely begins before tankers full of the stuff have been poured into a vast pit. After water, concrete is the second-most consumed material in the world, more than wood or steel or coal – and it is cement that makes concrete possible.

Cement is invaluable, in part, because it’s so cheap, and for cement to be cheap, it has to be what Ian Riley, the CEO of the World Cement Association, calls “a local business”. Factories have to be situated close to quarries of limestone, the main raw material, so that the mineral can be gouged out of the earth and ferried in at little cost. “But you also can’t transport the manufactured cement very far, because trucks are expensive,” Riley told me. “If you’re competing with another cement company, and the customer is closer to that other plant, you’re in trouble.” In China, where Riley once worked for Holcim, a cement plant’s potential market falls within a 60-mile radius. In Europe, he said, that extends to perhaps 120 or 190 miles. Almost no one exports cement across or between continents. It’s more efficient to open a multitude of factories instead – which is why Lafarge already owned hundreds of plants around the world by the time it bought the one in Jalabiya.

As a company, Lafarge is nearly as old as modern cement. In 1833, just nine years after an industrial cement-production technique was developed, Auguste Pavin de Lafarge started his company, mining limestone from his family’s quarry in south-east France. Its first major international project was to deliver 110,000 tonnes of cement for the construction of the Suez Canal in the 1860s. During the second world war, Lafarge sold cement to the Nazis to build a series of fortifications and bunkers called the Atlantic wall, hemming the coast of France. A couple of years after its 2015 merger with Holcim, Lafarge’s CEO said in an interview that he’d be happy to supply cement to help build Donald Trump’s wall on the US-Mexico border. “There are other clients who will be stunned by this,” Jean-Marc Ayrault, France’s foreign minister at the time, said in March 2017. “Lafarge says it doesn’t do politics … Very well, but I would say companies … also have social and environmental responsibilities.”

A casual visitor from the 1960s to a cement factory today would find much of it familiar. “It’s loud everywhere, for starters,” Riley told me. In many plants, noisy mills use steel balls to crush limestone, clay and other minerals. There’s also the din from banks of fans throughout the plant, especially connected to the kiln, a coal-fed oven that can heat up to 1,450C – a quarter of the temperature on the surface of the sun – and transform the pounded mix into lumps called clinker. A few chemical additives and a lap in a long kiln later, clinker is re-pulverised into the final product. “If you’re close to the kiln – oof! – it’s hot,” Riley said. “For some jobs, you have to wear a heat suit.” Cement and concrete account for around 8% of global carbon emissions. Between that, and its consumption of a tenth of all industrial water use, and its despoiling of the natural world, the industry is emblematic not only of the 20th century’s progress, but of its degradations as well.

The cement action is all in China these days. In western Europe and North America, Riley told me, cement consumption has been flat for years – their cities and bridges largely built out, their urbanisation close to complete. A couple of decades ago, the old cement titans of the west sought new customers by looking to China, India, Latin America and the Middle East. Usually, Riley said, these strategic moves happened through takeovers and acquisitions. Which was why Lafarge, wanting to sell cement into the oil-fuelled construction boom across the Middle East, came to buy Egypt’s Orascom Cement for $12.8bn in 2008, inheriting not just its clients and factories in Turkey, Pakistan, North Korea and Algeria, but also its plan to build a new cement plant in Jalabiya, Syria.

* * *

When Lafarge finished building its factory, in 2010, at a cost of about $680m, it became the biggest cement producer in Syria overnight. Roughly 350 full-time employees and another 350 contract staff worked on site – either in the factory, or in the adjoining power plant staffed mostly by a Chinese firm. Every day, the plant pounded out 8,000 tonnes of cement, to be sealed into 50kg bags or hauled away in tankers.

In the dispatch office, a shaven-headed man named Samee Hassan helped control the entry and exit of trucks, weighing them as they came in and out. Distributors bought the cement and sold it on to their customers across northern Syria. At $60 a tonne, Lafarge made half a million dollars a day in sales. The pace was lively from the minute the plant started operations. Once Hassan worked for 36 hours straight. “The market needed cement urgently, so the company put a lot of pressure,” he said.

By the summer of 2012, the incipient revolution against Bashar al-Assad’s ruthless regime had mutated into a complex set of armed insurgencies. Kurdish factions as well as the Free Syrian Army, started by officers who had defected from Assad’s military, took loose control of the area around Jalabiya. In June 2012, Lafarge evacuated its foreign employees – most of them French – from Jalabiya and Damascus; Pescheux moved to Cairo, to dispense orders from afar. That summer, Lafarge began making monthly payments to militant groups, so that the trucks carrying in limestone and coal or carrying out cement could pass unimpeded. As additional insurance, the company installed crash barriers – made of concrete, of course – outside the entrance. The factory’s risk manager, Jacob Waerness, a former paratrooper in the Norwegian air force, drove his Toyota Fortuner to Beirut so he could have it plated in armour.

One day, not long after Lafarge had moved its expats out of Syria, an electrical maintenance engineer, whom I’ll call Mohammed, told me that he ran into Waerness in the factory. Mohammed asked what he was doing to evacuate the local team.

Nothing, Waerness allegedly said. Lafarge classified employees according to risk, he told Mohammed. For expats, the risk level was red. For Syrians, it was a mere yellow.

What was the difference between expats and locals, Mohammed asked.

If he didn’t like it, Waerness said to Mohammed, he could resign. (Waerness told me he couldn’t respond to questions. He wrote a book in Norwegian recounting his time in Jalabiya, titled Risk Manager in Syria, but it doesn’t mention this incident. He does recount how strict Lafarge had to be with its local employees as the dangers around Jalabiya grew: “Military methods had to be used, otherwise they would not have come to work.”)

Shortly afterwards, when Assad’s regime began bombing Manbij, the small city where Hassan lived with his wife and two children, he decided to send his family to a safer location in western Syria. Hassan took unpaid leave for a month and stayed with them until his manager called to reassure him that the factory was taking precautions to keep its staff safe. In a chartered minibus, along with eight other employees, Hassan set out for Jalabiya. When they were just a couple of miles away from the factory, five rebels from the Free Syrian Army, all carrying Kalashnikovs, stopped the minibus and diverted it. The passengers were told to keep their heads down, so that they couldn’t see where they were going. One of the rebels made a phone call and said: “The bird is in the cage.” Hassan and his colleagues had been kidnapped.

Hassan found it difficult to talk to me about the three weeks during which they were held in the basement of an old building in Manbij. To a Spanish documentary crew a few years ago, however, he offered some details: “I prayed for my death to be quick. Then they stripped us. One of them burned me with a cigarette in my face.” The rebels wanted a ransom. “They asked us to call the company, and they gave us a phone with Jacob Waerness’s number,” Hassan told me. “I swear by God! That means they’d already had dealings with him!” (In his book, Waerness wrote that he wasn’t surprised the kidnappers had his number, because “information and people were circulating between the different groups in Manbij”.)

It was an absurd situation: a militia that had already been earning protection money from Lafarge was now squeezing the company for even more money by holding its staff for ransom. The company agreed to shell out roughly $200,000 in ransom. Waerness bundled the cash into black rubbish bags and drove his Toyota to a spot near the Turkish border for a midnight exchange. Once released, Hassan spent two days back at the factory. Then he returned home, where he learned that his wife, pregnant with their third child, had suffered a miscarriage.

Hassan’s abduction, as well as those of other Syrian employees, led Sherpa to accuse Lafarge of endangering its employees’ lives – a charge it included in its original complaint, alongside complicity in crimes against humanity. (Lafarge is also being investigated on two other charges: financing a terrorist group, and violating an embargo.) This past January, France’s supreme court threw out the charge that Lafarge put its employees in danger, arguing that French labour laws do not apply to the Syrian operations of a company headquartered in France. “We found that part of the decision appalling,” one of the lawyers involved in the complaint told me.

The metaphor of the frog in water brought slowly to a boil, and thus being cooked without knowing it, is scientifically inaccurate, Waerness wrote in his book – but it was true to Lafarge’s situation in Syria. By the end of autumn in 2012, Lafarge’s managers in Cairo, Jalabiya and Paris were dialling into a crisis unit meeting every week. But what an ordinary western company would have “considered a real crisis became, for us, as the weeks went by, something banal, and our tolerance threshold for negative incidents became much higher”. Just a few days after the kidnapped employees had returned, Waerness began hearing of a newly brewing crisis. IS had moved into the neighbourhood.

* * *

Even for a lifer in the cement business, a job at Lafarge can feel like an education. “The company is wealthy with knowledge,” Amr Nader, a former Lafarge executive, told me. The son of an Egyptian cement consultant, Nader got his first cement job at the age of 16, as a trainee kiln operator in Cairo. Today, as a Dubai-based consultant, Nader wears natty suits and his hair is pulled tightly back into a bun, but he told me with some pride that he’d worked plenty of sweaty, blue-collar cement jobs before scurrying up the ladder. He spent years with Orascom, and then joined Lafarge after the acquisition, working in Lyon and Cairo. “You get exposed to a huge variety of technologies and societies,” he said. “And it was the highest-paying cement company: business-class travel, five-star hotels. For a guy like me, being given an Amex card with a $50,000 limit, and being told that I can use it for whatever I wish, as long as it’s not personal expenses – well, it was a very good life.”

But Nader also found Lafarge a rigidly hierarchical place. “Technically, people on the ground have autonomy to make decisions, but the decisions have to travel back to Paris to be confirmed,” he said. Usually, employees obeyed Paris rather than speaking their minds. Nader left Lafarge in April 2013, upset that he’d been passed over for a promotion. “The role was given to a Frenchman,” he told me. It was that kind of company, he said, perhaps soured by his experience: “If a position was open, I felt like it would go to a non-French person only if no French employee wanted it.”

In a trilogy of case studies, Ashok Som, a professor at France’s ESSEC business school, quoted some Lafarge managers who described their company as “short-term oriented”, with even regional decisions being taken by top executives in Paris. The “use of common sense is rare”, one said. Another remarked that Lafarge has “rules for everything, accurately and methodically documented, but no one follows the rules”.

The resultant corporate culture has, over the course of the company’s history, borne distinctly neocolonial overtones. In Morocco, in a housing complex called Cité Lafarge that the company built in 1932 for factory workers, electricity was rationed and running water absent altogether well into the 1970s. Just over a decade ago, Lafarge won the right to quarry limestone from an Indian forest and transport it by a 10-mile conveyor belt over the border to a factory in Bangladesh, despite the protests of Indigenous communities worried about the project’s ecological cost. In Jordan and Egypt, Lafarge has been accused of using low-paid subcontractors to do the most hazardous tasks. (Lafarge claims that its businesses in Jordan and Egypt operate in line with local and international labour standards.) It is hardly unusual for multinationals to be exploitative and extractive. But unlike oil companies or mining giants, cement manufacturers rarely attract attention. Cement itself is as invisible as it is ubiquitous.

Nader visited Jalabiya often in 2010 and 2011, when northern Syria was still safe. In Aleppo, 90 miles west of the factory, he could have breakfast in a pavement cafe and dinner in a shisha bar. Even in 2012, when Lafarge began paying off militant groups, it was possible to keep rationalising the situation, Nader said. “For any heavy industry company in any place that isn’t western Europe or the US – say in Asia, or sub-Saharan Africa, or even some parts of eastern Europe – this was a normal situation, where you pay bribes to some groups on the ground to ensure the passage of your trucks,” he told me.

Lafarge was also reluctant to give up so quickly on its new $680m asset. The only way for the factory to make its investment back, the company decided, was to have it keep grinding out cement – in whatever way possible. “They didn’t tell us in so many words,” an employee at the factory told me, “but it was obvious what was happening. Lafarge had made a deal with the devil.”

* * *

The emails that flew between Lafarge Syria’s executives in 2013 and 2014 are an ample chronicle of self-interest and subterfuge. Among the chief correspondents was Firas Tlass, the son of a former defence minister who had since withdrawn his loyalty to Assad. Tlass hadn’t lived in the country since 2011, but he remained Lafarge’s chief fixer. To make its monthly payments to armed groups in northern Syria, Lafarge used Tlass as an intermediary.

Tlass sent Pescheux, Lafarge Syria’s CEO, regular updates on the groups he was paying off, and Lafarge reimbursed him. (Neither Pescheux nor Tlass responded to requests for interviews.) Pescheux had to hassle Tlass to send invoices that were sufficiently evasive. In December 2012, Pescheux recommended that all invoices be on the letterhead of a new company located outside Syria: “This will avoid problems with Syrian authorities and our auditors.” The following April, he sent Tlass detailed invoicing instructions that would “make things more ‘presentable’ and help us a lot”. Pescheux added: “Please do not mention my name on this invoice.”

Early in 2013, Tlass referred to a new group in his updates: the al-Nusra Front, an al-Qaida chapter that had taken Raqqa, and that had already been declared a terrorist organisation by the US. Lafarge started paying them: 200,000 Syrian pounds a month at first, rising to 325,000 soon after. In June, Waerness wrote to Pescheux that IS was gathering strength in the area; soon after, IS set up checkpoints on the roads around Jalabiya. Lafarge agreed to pay Tlass $75,000 a month, so that he could disburse funds to both groups – but the money would only come to him if Lafarge kept selling at least 75,000 tonnes of cement every quarter.

Lafarge routed its payments to IS and other groups through intermediaries, and sometimes wired the money from a subsidiary in Egypt to Tlass’s accounts in Lebanon and the UAE. “This is the way we intend to proceed to severe [sic] any suspicion in connecting [Lafarge and Tlass],” Pescheux wrote in an August 2013 email. Truck drivers received handwritten passes to present at checkpoints, issued in the name of “The Islamic State of Iraq and al-Sham” and stamped with the IS flag. Pescheux’s request to Tlass, that the name “Lafarge” never appear on such passes, went unheeded. Well into 2014, the passes bore the words “Lafarge Cement Company,” instructing IS militants to let vehicles pass because Lafarge had “fulfilled their dues to us”.

After IS captured Raqqa, in January 2014, large swathes of the area around Jalabiya fell under its control. By this time, Lafarge had already begun buying fuel and raw materials from IS-approved vendors and quarries. (One of the emails to Lafarge came, according to its signature, from “The Emir of the Investment Office in the Islamic State in Iraq and Sham”.) To the monthly payments, Lafarge added a “revenue sharing” deal, which included paying IS for every tonne of cement sold – an incentive for the militants to smooth the way of the cement to its customers.

In May 2014, IS proposed stopping the import of Turkish cement entirely, and asked Lafarge what might be in it for them. In an email, Pescheux laid out the business case: a heavy toll on Turkish imports would not only be a new stream of income for IS, but would also increase Lafarge’s sales – and thereby also the fees paid to IS. Lafarge was tempting IS with a split of its profits. In an internal email in July 2014, Christian Herrault, Lafarge’s executive vice-president of operations based out of Paris, wrote: “We have to maintain the principle that we are ready to share the ‘cake,’ if there is a ‘cake.’”

By this time, the violence perpetrated by the world’s most famous terrorist group was daily fodder for the global news media. Early that August, just two days after IS launched its widely publicised attack on Yazidi villages in Iraq, Tlass and Frédéric Jolibois – who’d replaced Pescheux a month or so earlier – discussed a new revenue-sharing deal with IS. What would the margins be for Lafarge, Jolibois wondered in an email, before adding in a post-script: “We should not forget that Isis is a terrorist movement.” Later that month, well after the US authorised airstrikes against IS, and around the time IS released a video showing its beheading of the journalist James Foley, Lafarge’s executive committee was still chewing over the agreement with IS to tax Turkish imports.

Perhaps Lafarge was confident of hiding its tracks. It had been funnelling funds through 54 different bank accounts, including at least one personal account, to make transactions hard to trace, according to one of the ongoing lawsuits in the US. For its go-betweens, Lafarge made out vague contracts for services such as “environmental consultancy”, so it could send them the money intended for IS. Executives used their personal email addresses to discuss their dealings with IS. (Nader told me he couldn’t believe “how stupid they’d been to even put down their names and Daesh [IS] on the same piece of paper”.)

Only on 11 September 2014, the day after President Barack Obama announced his intent to destroy IS, did Lafarge’s lawyer suggest suspending payments. Jolibois rejected any thought of shutting the plant down for a while and returning to it after the pending merger with Holcim was complete. There was no way of knowing “that the area will have been freed from the grip of Isis”, he wrote, “nor that it will be free from it for years”. If he saw no alternative to continue making cement and paying the terrorists, IS provided one when, just a week later, it snatched the factory for itself.

* * *

At a remove of a decade, Lafarge’s decision to feed a catastrophe just to sell cement is even more mystifying. Lafarge’s top brass was certainly keen to seal the merger with Holcim, which was finalised in July 2015. After the merger, Holcim conducted its own inquiry of this episode, concluding that, “very simply, chaos reigned”, and that the “‘can-do’ approach” of Lafarge’s managers led them to neglect “the legal and reputational implications of their conduct”. The statement said nothing about the human cost of Lafarge’s financing of IS.

One former Lafarge executive, who asked to remain unnamed, offered me another theory for the company’s persistence in Syria. He’d often been asked to evaluate cement plants in Asia or Africa before Lafarge bought them, and on one such trip to the Democratic Republic of the Congo, in the thick of the civil war there, he took a helicopter to the factory from the Ugandan border. On the chopper, he saw a couple of Frenchmen who weren’t, to his knowledge, on any Lafarge team. Once at the plant, he said, “I never saw them until it was time to come back.” In a country beset by a civil war, he reasoned, “they must be collecting intelligence”. When he tried to talk to one of the men, “he was dry and stiff. Later I asked some older Lafarge guys about this, and was told not to ask such questions.” This happened again on trips to inspect possible Lafarge acquisitions in Iran, Pakistan and North Korea – all countries that French officialdom would find it otherwise difficult to penetrate.

The executive thought this must have been the case in Syria as well. “The French government definitely knew Lafarge was paying militants to [let the company] stay in the country,” he claimed. “France just didn’t want Lafarge to get out of Syria at that time.” Between 2012 and 2014, Jean-Claude Veillard, a former special forces marine who was Lafarge’s security director in Paris, met with French secret services at least 33 times, according to the newspaper Libération. Last year, Tlass claimed to a documentary crew that, in 2015, French intelligence officials paid him hundreds of thousands of euros in cash to share information about Assad’s regime. This was before Lafarge’s deals with IS became public, but not long after the deals themselves – and it hints at how thirsty French officials were for on-the-ground intelligence about Assad’s Syria.

In the ongoing French case, Herrault, Lafarge’s operations chief, has stated that the foreign ministry encouraged the company to remain in Syria, ostensibly to keep the “French flag” flying. (The ministry has denied this.) Apart from Herrault and other Lafarge executives, investigators have also questioned the former foreign minister Laurent Fabius and several diplomats. Fabius has said he has “no clear memory” of Lafarge’s operations in Syria, and that he was never informed about its dealings with armed groups – even though he met Bruno Lafont, Lafarge’s former global CEO, a number of times between 2013 and 2015. Lafont himself, having resigned in 2015, claimed to Libération last year that if Lafarge really had been “infiltrated” by French secret services, that was news to him. When the episodes were reported in the French press, Lafont said, “I fell off my chair.” (Lafont also told Libération that he was never aware of payments to terrorist groups, and that in 2013, he had stressed to a colleague that he would, if necessary, willingly close the factory to protect his employees.)

The internal Lafarge emails that I saw, though, held no trace of state-sanctioned espionage; instead, they’re all about the far more banal desire to make more money. No one put it better than Tlass. In March 2014, he sent an email to Lafarge Syria’s executives about the difficulties of the situation – although he didn’t once mention the moral failings of funding the IS treasury. Doing this work was jeopardising his health, he said, and sometimes when he talked to IS men, “carrying their rifles … like they own the world,” he felt “like a clown entertaining children”.

But business was good. They were clearing $2m in profit every month, and paying less than a quarter of that to militants. Cement was, at the time, in such short supply in destroyed Syrian cities that a 50kg bag sold for more than 500 Syrian pounds, double its earlier rate – a classic example of wartime profiteering. (In total, Lafarge sold more than $70m worth of cement during the period when it conspired with IS.) Ending its arrangement with IS would entail writing off not just millions of dollars in income but also the factory itself. The question, Tlass pointed out, was: “Is Lafarge able to bear a loss of about $600m, because we are operating in a difficult situation?”

The answer, everyone seems to have decided, was: no.

* * *

It has never exactly been a secret that corporations sometimes stoke conflict in their pursuit of profit. The foremost exemplar, the East India Company, ran a business model premised on just that method, starting wars in order to sell opium in China and torturing Indians to disclose their treasures. But although companies have been convicted on other charges – such as stock manipulation and insider trading, in the case of the investment firm Drexel Burnham Lambert, in the 1980s – prosecutions for war crimes and crimes against humanity are a much more recent phenomenon. “At least 15 cases have been investigated or litigated over the past quarter-century, in different jurisdictions,” Mark Taylor, the human rights scholar, said. “Most have not reached trial, and all have proceeded very slowly.”

In one way, companies and their executives are easy to indict. As in the case of Lafarge, their emails, financial records, memos and all the rest of their documents that streamline their business also testify to their misconduct. But they can be elusive in other ways. Two former executives at Lundin, a Swedish oil giant, are being tried for war crimes after the company allegedly persuaded the Sudanese military in 1999 to “pacify” an area so that Lundin could extract its oil. Twelve thousand people died. The trial, which began a year ago and will run until the spring of 2026, will be the longest in Sweden’s history, and the executives face possible life sentences if they are convicted. In the interim, Lundin’s owners shut the company down and sold its assets across the border in Norway. By simply ceasing to exist, Lundin can escape any potential liability in Swedish courts.

If a French court ever finds Lafarge guilty, the odds that any former executives will go to prison might still be slim. The worst that is likely to happen has already happened to some of them: they’ve lost their jobs, but have still landed on their feet. Lafont, for instance, received an €8m exit package, of which the French state seized €2.5m. Last year, he grumbled to Libération that he’d been on a break since 2016, even though he had actually served on the prestigious boards of companies such as ArcelorMittal in that period. Pescheux moved to head up a Lafarge subsidiary in Kenya. He did not resign until 2017, just before being charged by a French court, although a company release said that he would be “relocating within the LafargeHolcim Group pending retirement”.

Only in October 2022 did a Lafarge statement finally make clear that Pescheux and other executives involved in collaborating with IS were not on its rolls any longer. Lafarge itself is a vastly shrunken entity today, present only in France and about a dozen other countries.

It’s unlikely that any financial penalties levied by a French court will be distributed as reparations among all the people affected by these crimes. Lafarge’s $778m fine went into the US government’s pocket. The number of Yazidis who became US citizens and are therefore eligible to sue Lafarge in the US is a small fraction of those harmed by IS. Hundreds of Syrian employees who felt trapped in the Lafarge plant, believing their lives to be perpetually at risk while spending their days making cement, are unrepresented in any lawsuit. The same goes for the tens or hundreds of thousands of others targeted by IS – which was financed, in part, by Lafarge’s payments, and later by the sale of the cement remaining in the Jalabiya warehouse, after the plant fell to IS in September 2014. Over the following weeks, IS sold the cement and other materials left behind, earning at least $11.5m in the process – a final round of profit squeezed out of Lafarge. Through one of its intermediaries, Lafarge kept negotiating with IS, hoping to regain the factory and begin selling cement again. It wasn’t to be.

Cement plants can enjoy a lifespan of half a century or more. The Jalabiya factory lasted just 14 years. IS held on to it, but was finally driven out of the area by a US-led military coalition, which used the compound as a base. In 2019, as President Donald Trump pulled out US troops from Syria, two American F-15s bombed part of the factory that had been repurposed into a storage bunker, to prevent munitions from falling into the hands of militant groups. Through the pandemic, the factory was occupied by Kurdish forces. This past January, as part of an air campaign targeting the Kurds, Turkey destroyed the Lafarge factory. In videos shot after the attack, thick smoke pours upwards from the arid land into the bleached-blue sky. The buildings are mangled. The only things that seem to have survived, at least in the videos, are the white, waist-high crash barriers made of concrete.

• Follow the Long Read on X at @gdnlongread, listen to our podcasts here and sign up to the long read weekly email here.