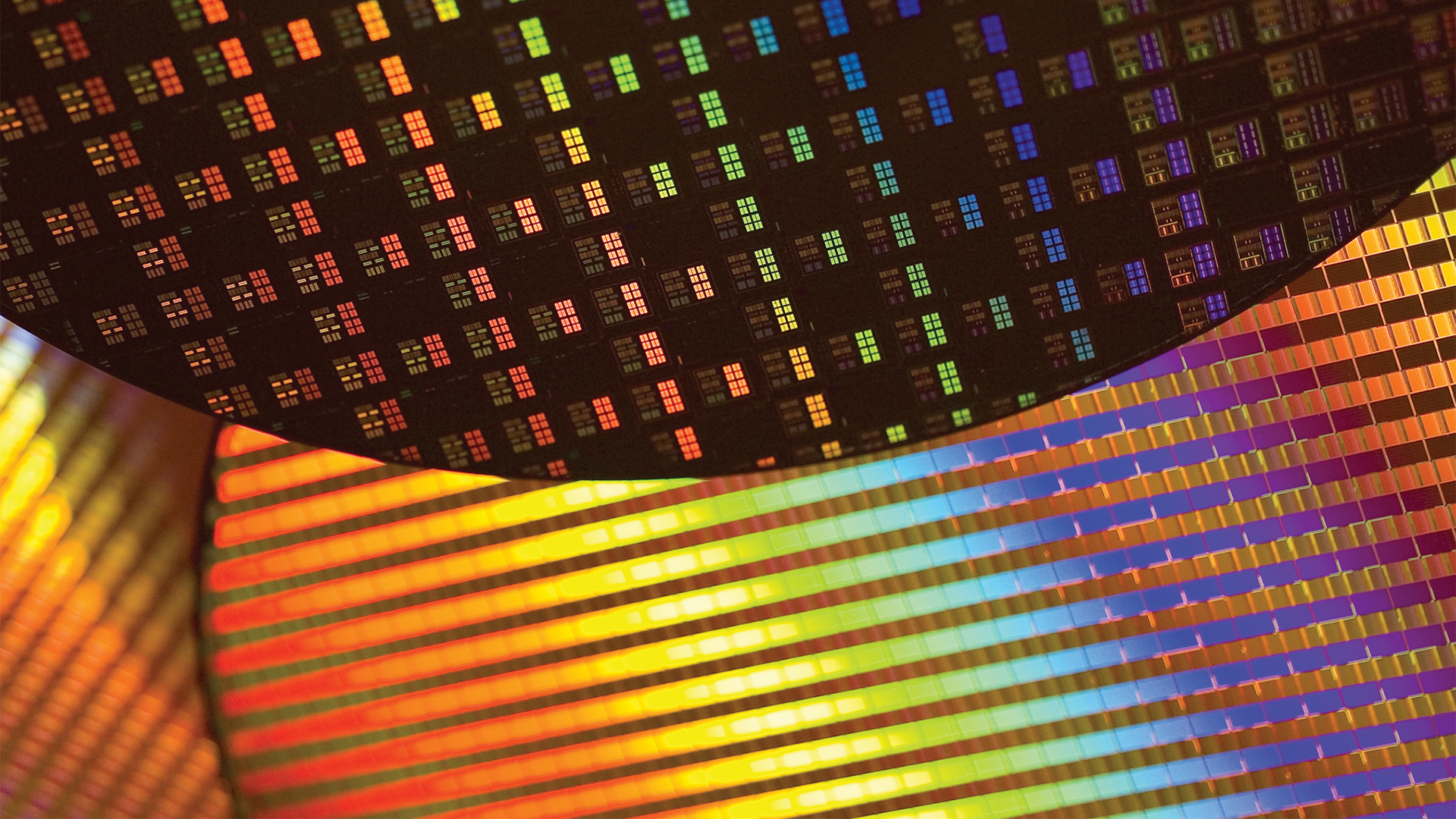

According to United Daily News, Wu Cheng-wen, the head of Taiwan’s National Science Council, believes mainland China’s semiconductor industry is more than ten years behind Taiwan’s. While some believe that Taiwan’s chip sector is only three years ahead of that in mainland China, Wu Cheng-wen says that as TSMC advances to 2nm, its China-based peer can barely produce 7nm chips. But there is a significant catch.

Wu Cheng-wen expressed skepticism during a session at the Legislative Yuan’s Education and Culture Committee, where he was invited to discuss Taiwan’s research sustainability and policy communication. He responded to questions about a Japanese media report — based on an examination of the application processor in Huawei’s latest smartphone — suggesting that China’s semiconductor capabilities were rapidly closing in on TSMC’s, only lagging by three years. However, Wu believes the gap is still significant, possibly exceeding ten years, especially with TSMC’s continued development of advanced manufacturing processes.

Huawei’s latest Mate XT Ultimate smartphone is based on Huawei’s Kirin 9010-series processor, presumably made by China’s contract chipmaking champion Semiconductor Manufacturing International Corp. (SMIC) using its 2nd Generation 7nm-class process technology that offers performance and transistor density comparable to TSMC’s N7 (1st Generation 7nm-class process) in terms.

TSMC began using its N7 in 2018, and SMIC’s 2nd Generation 7nm-class node entered mass production in 2023, so SMIC was five years and two process nodes behind last year. However, this ‘math’ is not without caveats.

TSMC began to use EUV lithography in 2019 – 2020 with its N7+ and N5 process technologies, enabling advantages across power, performance, and area metrics. Without EUV, achieving comparable PPA will be tricky and perhaps economically unfeasible. Will SMIC (and its partners like Huawei) be able to develop one or two manufacturing nodes — say 5nm and 3nm-class — over the next five years without EUV? Industry experts say that it is possible, but TSMC will remain ahead with 2nm-class, 1.6nm-class, and then 1.4nm-class process technologies that it will have by 2030, so it will still be ahead.

But there is a significant catch about leading-edge nodes in general. In China and Taiwan, only TSMC and SMIC are working on these sophisticated production technologies. Others—UMC, Vanguard, Hua Hong, just to name a few—continue to build chips on mature fabrication processes, such as 28nm, 45nm, and even thicker. UMC does not seem to be advancing beyond 14nm/16nm-class nodes, and from this point of view, the Chinese and Taiwanese semiconductor industries seem to be getting closer together.