It's a rejuvenating peak of sunshine on a cloudy day or the bright beam of a lighthouse cutting through dense fog — the movement of light is pretty badass.

Light is also a powerful scientific phenomenon. Scientists now have a plan for how to use it to revolutionize biomedical robotics.

Stretchy robots designed to rummage through your veins or seek out emerging tumors could be the future of personalized medicine, but tracking the complex movements of these tiny bots is easier said than done. Existing sensors are better equipped to measure individual movements of static materials than they are the complex twisting and bending of a soft robot.

Using stretchy fiber optics with light embedded inside, researchers in a new study more accurately detected and measured complex movements in real-time, including the movement of individual finger joints when worn like a glove.

This innovation could change how mechanical tools interact with the human body, including a prosthetic limb upgrade to incorporate a more life-like sense of touch.

Measuring changes in light has long been a secret weapon of scientists trying to measure less tangible changes in materials.

In robotics, one way this has previously been done was using silica-based distributed fiber optic sensors (DFOSs.) By measuring how light passing through these fibers react to stimuli like pressure, heat, or vibration, these materials provide feedback about the movement of an object.

But there's a catch, Hedan Bai, the study's first author and Ph.D. candidate at Cornell University tells Inverse. DFOSs work best when incorporated with static materials, meaning that these benefits barely translate to the kind of dynamic materials used in biomedicine.

"Many previous stretchable sensors are not able to differentiate the many deformation types with one output ... and therefore need extended system integration or machine learning algorithms," explains Bai. "The question this project tries to answer is if we can fundamentally improve the functions of a single stretchable sensor."

Due to this complication, Bai continued to explain that medical robots have largely relied on vision alone to make these measurements.

"Right now, sensing is done mostly by vision," explains Bai. "This skin is a way to allow ourselves and machines to measure tactile interactions in a way that we now use the cameras in our phones."

But using vision to make tactile measurements is like using hearing to see a new city — it can only get you so far. To close this research gap, Bai and colleagues instead decided to see if they could incorporate light-sensing from DFOSs into a stretchy material compatible with biomedicine applications.

The findings from this study were published Thursday in the journal Science.

Building a super sensing glove — In their study, the researchers embedded two polyurethane optic fiber cores inside a stretchy silicone coating. To help measure dynamic movement, one core was made clear while the other was interspersed with different colored dyes.

The benefit of incorporating light, as opposed to another tactile form of measurement, into these fibers is that light can provide rich information about physical interactions thanks to how its wavelength, polarization, or direction might change, Bai explains to Inverse. By measuring the intensity and color of light in these stretchable fibers, the researchers can make detailed measurements without needing to boot up a machine learning algorithm.

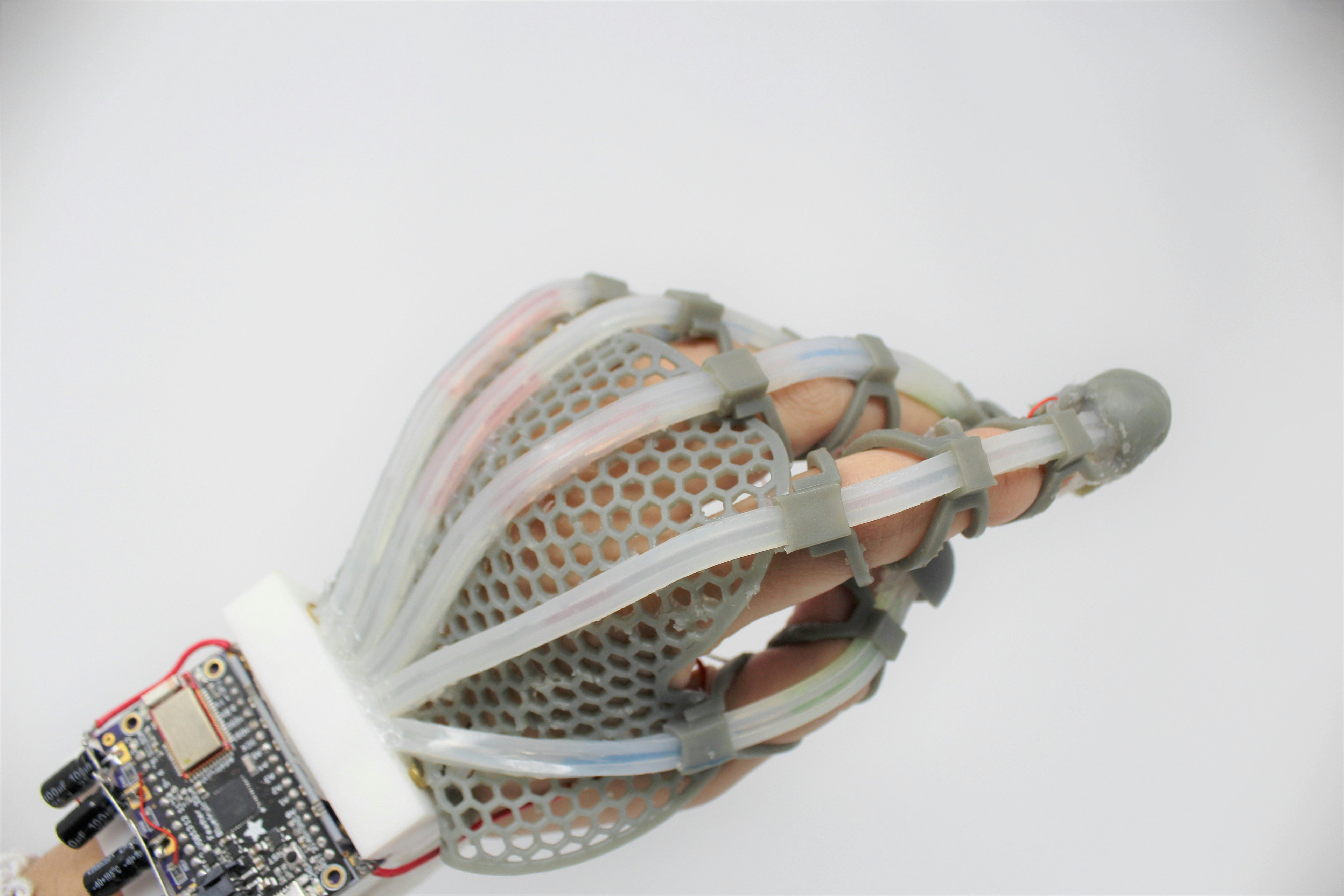

To test this out in practice, the researchers crafted a futuristic glove with one bundle of stretchy fibers laid out on each finger. The wearer slowly bent and moved different fingers to see how well the material could track its movement.

When undeformed, clear light passes through both cores. But when a finger begins to move, different colored lights start to glow. Different strengths and types of movement result in a different light pattern between the two cores, the authors explain, which helps determine the location and type of movement being made.

Bai tells Inverse that this information is passed along to a computer via Bluetooth to create a visual model of the motion in real-time.

The future of sensing — As this research continues to mature, Bai tells Inverse that there will be exciting applications for everything from medical tools, to internal soft robots and even prosthetic limb development.

"In biomedicine, this sensor offers a safe, comfortable and multifunctional way to interact with our organs and measure the mechanical stimuli they are experiencing," says Bai.

And beyond medicine, Bai says that this technology could also be used in VR and AR to enhance immersion and physical sensation in these environments.

In the future, says Bai, an AR assistant may make use of these sensing gloves to teach you how to rotate your tires instead of your father-in-law.

Abstract: Silica-based distributed fiber-optic sensor (DFOS) systems have been a powerful tool for sensing strain, pressure, vibration, acceleration, temperature, and humidity in inextensible structures. DFOS systems, however, are incompatible with the large strains associated with soft robotics and stretchable electronics. We develop a sensor composed of parallel assemblies of elastomeric lightguides that incorporate continuum or discrete chromatic patterns. By exploiting a combination of frustrated total internal reflection and absorption, stretchable DFOSs can distinguish and measure the locations, magnitudes, and modes (stretch, bend, or press) of mechanical deformation. We further demonstrate multilocation decoupling and multimodal deformation decoupling through a stretchable DFOS–integrated wireless glove that can reconfigure all types of finger joint movements and external presses simultaneously, with only a single sensor in real time.