The paddock-to-plate business model and short supply chains have allowed small-town retailers to sidestep most of the shortage problems faced by the large supermarkets.

Despite being an abattoir town, Tamworth has suffered meat shortages the same as everywhere else in Australia, something not lost on consumers – or employees of the supermarkets.

Tamworth local butcher Paul Avery, of Ford’s Butchery, hasn’t just survived during the shortages, but thrived over the past two years, picking up new customers as the shortages hit, many of whom have stuck around.

Avery’s small shop saw an increase of customers as meat cabinets in supermarkets started running bare.

“That happened when the pandemic started,” Avery said.

He estimates that maybe 20% of the customers who were refugees from the supermarkets during the shortages have stayed.

In fact, the demand is such that he has had to cut back on supply to some of his restaurant customers just to maintain stocks for his shop.

Avery raises “every piece of beef” sold under his Mountain View brand that passes over his counter at his acreage just 15 minutes away from the shop, a move that was originally done to ensure quality, as well as a bit of a nod to the traditional country butcher.

“Every small-town butcher used to have his own farm, his own chiller, and kill his own,” Avery said.

His lamb comes from a farm 32km north, in Bendemeer, from a farmer he knows and deals with personally.

Tamworth is a major centre for meat processing. Teys Australia, Thomas Foods International and Baiada Poultry all have major processing facilities in the town.

Paradoxically, Avery’s animals are slaughtered in Binnaway, two hours away, because the bigger processors based in Tamworth do not process small numbers of stock. Avery prefers heifers over steers, as he believes swapping carcass yield for tenderness is a worthy trade-off.

While larger supermarkets have had to grapple with the shortages of meat and other staples, smaller retailers with close contact with their suppliers have gained an advantage during Covid-induced shortages.

‘Very active in sourcing’

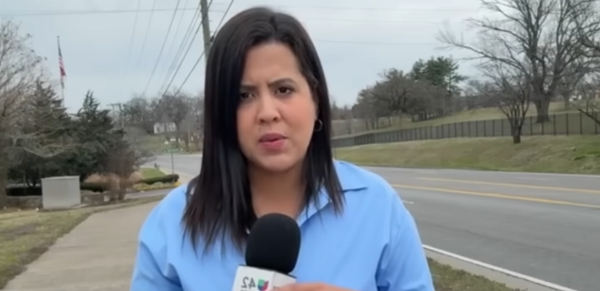

Amber Brown, the manager of Calala’s IGA supermarket, has been surprised at the amount of shortages the major supermarket chains have been experiencing, citing the store-level control she has over sourcing that Coles, Woolworths and Aldi supermarkets do not have.

“We’ve got a lot of people out there on the ground sourcing products,” Brown said.

Calala IGA is part of a small network of about 14 IGA stores run by Carlo Cavallaro, which Brown believes is small enough to still be flexible to rapidly adapt to changes.

Calala IGA has its own employees at a store level sourcing products, something larger supermarkets deal with at a higher level at the corporate headquarters, allowing Brown to adapt immediately to shortages that are specific to her store.

“We’ve got a produce specialist, we’ve got a meat specialist, we’ve got a deli specialist.

“They’re very active in sourcing: ‘If we can’t get something from this supplier this week, we suggest you go through this other supplier.’

“I don’t believe the majors have that flexibility. I think your majors are very structured.”

The Cavallaro IGA group operates a wholesale warehouse out of Avro Street in Tamworth, which it uses to service its surrounding stores. This facility includes a butchery and meat packing facility that has allowed it to keep meat on shelves – something that was an issue during the busy Christmas barbecue season for the major retailers.

Statements issued by Coles and Woolworths both cited the challenges of Covid and the staff shortages brought on by the pandemic.

A spokesperson for Woolworths stated the company worked with partners in Tamworth to complete the first steps of meat processing for beef and lamb cuts, before they were sent to a specialised facility to be cut and packaged.

“Over the last month, grocery supply chains have been severely impacted by Covid-related absenteeism, reducing the capacity of meat processors, distribution centres and transport networks,” the spokesperson said.

In a statement, Coles said recent increases in Covid case numbers in the community had required more people to isolate, which had impacted the availability of labour throughout the food supply chain in New South Wales.

“At a time when inventory levels were already reduced in the post-Christmas period, our distribution centres are receiving fewer inbound deliveries and we have fewer team members available to process and dispatch stock to our stores,” the statement said.