Australia's only silicon manufacturer may be forced to import coal as it struggles to secure a consistent supply of local timber to make its product.

Simcoa, based in Western Australia's south-west, would normally rely on charcoal derived from local jarrah to produce its high-grade silicon.

But due to the flow-on effects from a WA government decision to end the harvesting of native forests by 2024, the company said it only had access to half the amount it usually would.

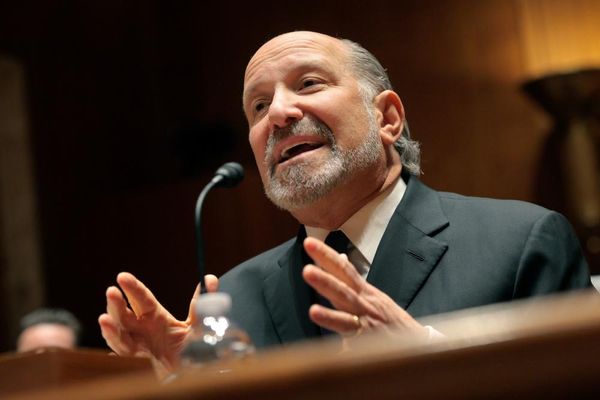

Simcoa's director of operations David Miles said without a suitable alternative, the company might have to triple the amount of coal it imported to keep running at full tilt.

"Normally we require around 140,000 tonnes of hardwood timber in the manufacturing process. This year we've received about half that," he said.

Mr Miles said the company was very concerned that it was having to consider alternatives to jarrah that were not as favourable.

How is timber related to solar panels?

A source of carbon is required in order to manufacture high-grade silicon, a key input used in solar panels.

This carbon source can be derived either directly from coal or through turning wood into charcoal through a heating process.

Not all types of timber are created equally though, as some types are thought to absorb additional minerals from the soil, which can affect the purity of the end product.

Mr Miles said jarrah was the best timber for the job and created a very high grade of silicon.

This high-grade silicon is used to make solar panels and other battery technologies.

Importing Colombian coal a last resort

Mr Miles said if they could not secure a consistent supply of timber, the company would have to import high volumes of coal from Colombia — the only country with a high enough quality product suitable for silicon manufacturing.

"Coal is globally a very adverse thing to do because it increases your carbon footprint," Mr Miles said.

State Forestry Minister Dave Kelly said he was not aware of any timber supply issues and he would have no part in the decision as to whether or not Simcoa decided to import more coal.

"They'll have to make commercial decisions about where they source their materials from," he said.

The minister would not acknowledge the implication that using coal as an input of silicon manufacturing was "bad for climate change".

Curtin University sustainability professor Peter Newman said the preferred source of carbon in silicon manufacturing is timber.

"We can grow trees specifically for that process," he said.

"We can't imagine a future with coal anymore, that has finished.

"The processes will require us to grow more trees as well as dig up more silicon and more lithium [because] these are the raw materials of the next economy."