Technology never stands still, and that’s just as true in cycling as any other industry. The past 12 months have seen major advancements: seatposts that seem to base their aesthetics on household fans, electronic shifting at its lowest ever price, and bike-fit philosophy that holds aerodynamics above all else.

With 2024 an Olympic year, this year’s track events have given us a glimpse of what might be arriving in years to come with cutting-edge technology being used in competition as national teams work within the confines of the UCI tech regs. What’s ridden on the boards is now a major driver of the top-end tech and design philosophies that appear on road bikes in years to come. Or earlier. Here’s a look at the technology we’re getting excited about and that could hit the shelves in the coming year.

Lower cost electric shifting

Electronic drivetrains are here to stay. They improve both shift speed and shift quality and, increasingly, they are proving to be just as reliable as cable-operated groupsets. That said, they still cost a lot of money, even after years of trickle-down technology.

SRAM’s cheapest AXS groupset, for example, the Rival eTap, comes in at £1,268 – still more than most entry-level road bikes for sale today. Meanwhile Shimano’s 105 Di2 costs £1,730. Inevitably, as time goes on this cost will come down, and we expect that the adoption of electronic shifting may be picked up across lower level groupsets in 2024.

A spokesperson for SRAM told us that they “expect the adoption of electronic shifting to continue to increase across more price points and platforms”.

Alongside the big marques continuing the fight to the bottom, 2023 has also shown the emergence of new brands causing a storm at the lower end of the market. Back in March, you could find L-Twoo’s eRX wireless electronic groupset, complete with hydraulic disc brakes for around $650 on AliExpress.

It might not be the go-to store for those looking to upgrade their bike with premium parts, but showed that electronic shifting at a lower price is attainable – and we think this market disruption is something we might see more of in 2024.

Split seatpins

An Olympic year means an abundance of track bike tech, and the 2023 Track World Championships in Glasgow have already proven this to be true once more. Every piece of equipment used in Paris next year has already been homologated for use in competition and historically track bike tech often finds itself in road cycling pretty quickly.

Look, TOOT, and the most recent Hope x Lotus track bike collaboration all have strange-looking split seatpost designs – not dissimilar to Dyson’s popular Airblade fan – in common. Cycling Weekly’s own columnist and expert Dr Michael Hutchinson thinks they could become a “fairly normal feature” in the cycling world. TOOT Racing’s head of design Romolo Stanco said the ‘double diapason’ seatpost design enhances aerodynamics, stability, and control.

“A more sophisticated aerodynamic flow management can produce greater advantages in high and constant speed disciplines such as TT and team pursuit or where the athlete intends to be exposed to clean air for a long time, for example in a breakaway,” Stanco said.

“In this case our simulations indicated that an acceleration of the air flow under the athlete’s body decreases the aerodynamic pressure and reduces drag considerably.” Similar examples seen on both the Look P24 and the Hope x Lotus track bikes show us that diff erent engineers are on the same page – but will your next road bike have a split seatpost design?

Despite the slightly alien form factor, we think it could catch on. From a materials science point of view, it’s pretty straightforward as the seatpost isn’t a component subject to large oblique forces, unlike the bottom bracket, for example. The gains are likely marginal like most non-position optimisations these days, but for those driven by performance, it’s hard to see a downside.

The obvious Achilles heel is the aesthetics – the design does look slightly strange, but those who favour out-and-out performance over looks will likely welcome the gains. The obvious avenue then would be on time trial bikes, where aerodynamic efficiency generally takes favour over a slight weight penalty, but it might not be long until they hit the road bike market too.

New bars for sprinters

Track cycling is arguably home to the strangest handlebar set-ups in cycling. These peculiar looking designs are in part down to the fact that track cockpits don’t require the fitting of shifters or brakes, but their non-conforming strange aesthetics are also aimed at optimising rider position over simply making aerofoil shaped handlebars – and this is something we think might bleed into the road cycling scene more noticeably next year.

Sprint handlebars, for example, are designed with a long reach, and low drop to put riders in a biomechanically efficient position for sprinting in the drops.

Compare this to handlebars on the road; they are wider, deeper and generally with less reach. Obviously, this is influenced by the longer distances covered on the road, but as various riders in the WorldTour have shown, there are huge gains to be made in position-based aerodynamics.

We expect to see a trend in narrower handlebars with a longer reach – something Pinarello has already experimented with in a prototype Most Talon handlebar for Luke Plapp this year.

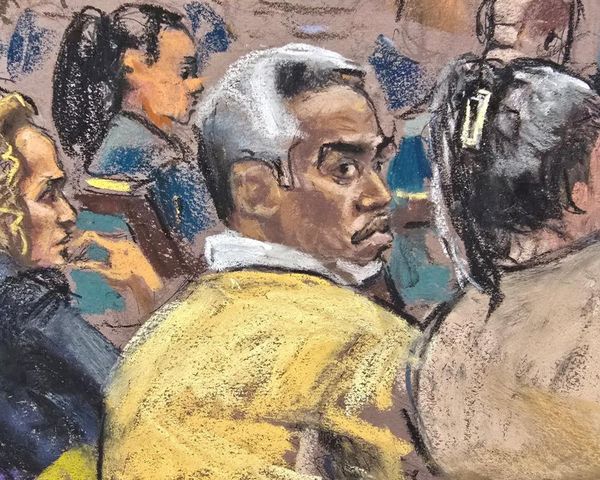

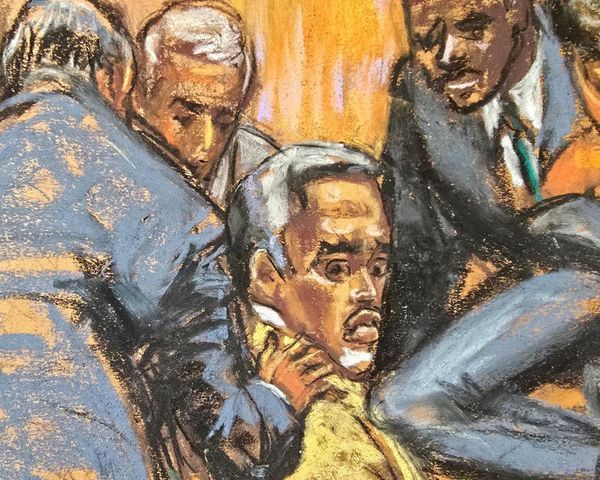

The end of cables

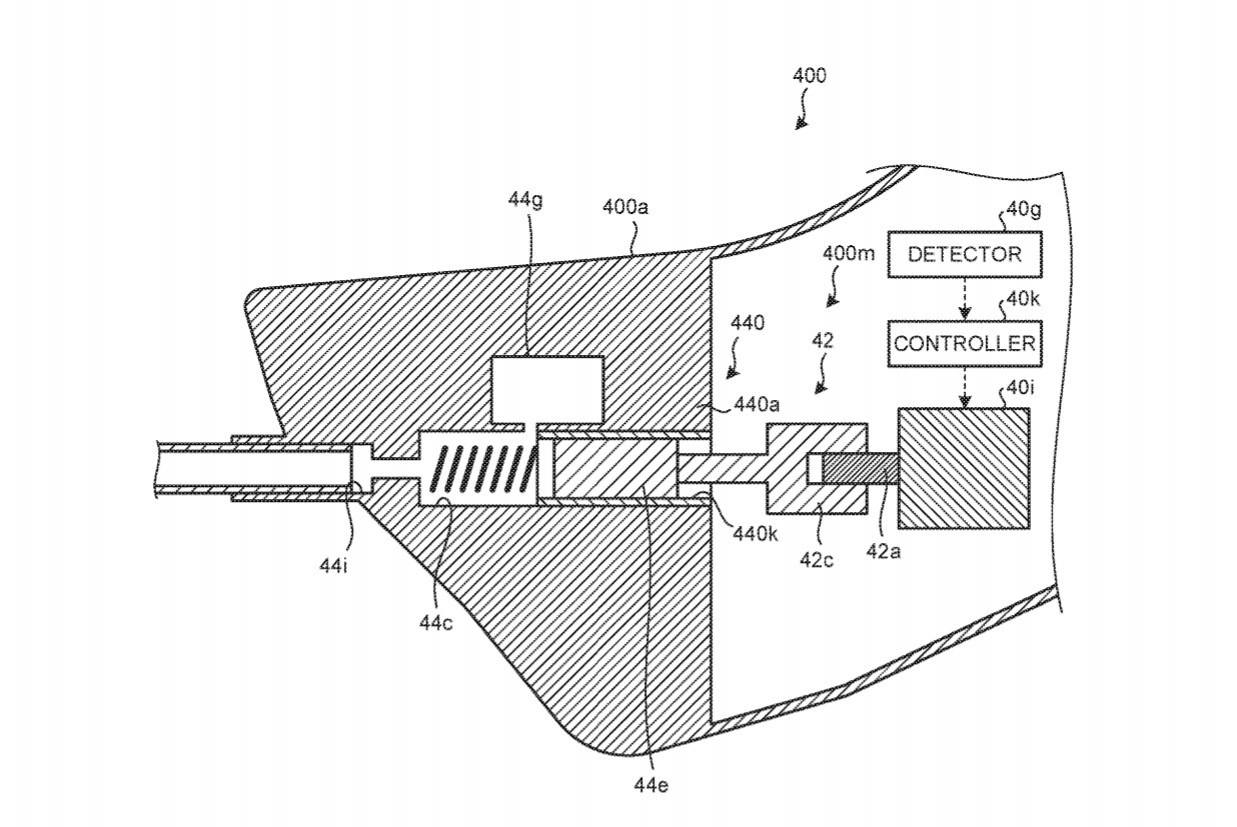

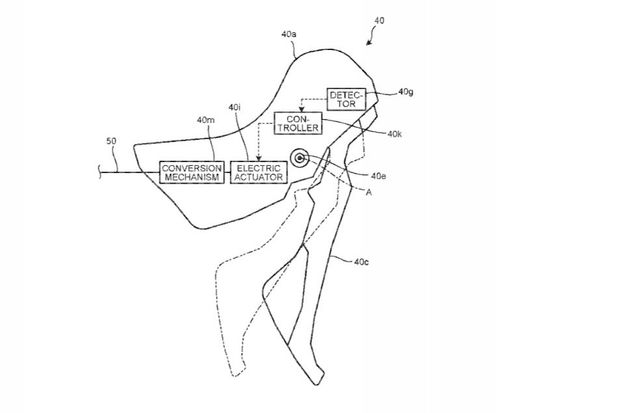

Wireless braking is probably a phrase that would terrify most riders. The thought of putting our safety in the hands of a computer system isn’t something that comes naturally to us, but electronically controlled braking is something Shimano has had its eyes on for more than a year. The Japanese component giant was granted a patent for a control system that logs brake lever movement as an electronic input, forwarding this to a motor, which in turn controls the hydraulic fluid and your brakes.

Shimano’s drawings indicate that its system would still have a reservoir inside the brake lever, and therefore be wired from lever to brake caliper, but the technology does exist to be able to make in-frame hydraulic hoses redundant.

A fully wireless system would have to house a hydraulic reservoir next to the brake caliper, something that has been around for years in the shape of the TRP Hy/Rd disc brakes which use a hybrid cable/hydraulic construction. Wireless communication between brake levers and calipers is certainly possible too, as SRAM has proven for many years now.

Alongside aesthetics, wireless brakes could potentially put an end to internal cable routing, which Phil Leah, managing director of Target Composites, tells us could make forks safer.

Simplification is often the route to good design

“Internal routing brought with it a lot of new complications,” he states. “Simplification is often the route to good design. There is less to go wrong and you can concentrate on getting things right in as efficient a way as possible. You can defi nitely make simpler designs safer and more lightweight as you don’t have as many variables to contend with.”

Should we trust electronic brakes?

As someone who has a firm belief in proper engineering, I personally think that if the correct due diligence and rigorous design and testing protocol are followed, then I would absolutely ditch my current brakes for wireless stopping power. We heavily rely on electronic systems in the automotive industry and transport sector already – so why not on our bikes too?

The caveat here though is that I think electronic brakes would require a large amount of testing before feeling natural to use; more so than any other technology on our bikes. Formula One drivers complained for at least two years about the unorthodox feel associated with regenerative braking when it was fi rst launched in the hybrid era. I think that similarly, we might be one or two iterations off a truly usable product, which would have seismic cost implications.

New gearing systems

Bicycle gears have been around in cycling in various forms for over 100 years, but since Campagnolo’s Grand Sport derailleur (1949), drivetrain systems have seen little fundamental change in their functionality. The number of sprockets has increased, and cables have been electrified, but the rudimentary parallelogram shifting design has remained almost the same. We think this long-standing design staple could form a real battleground for new tech development in 2024.

In recent years, there have been a number of new systems that aim to either replace or complement existing gearing systems, pulling in innovation from other industries.

Of particular interest is Driven Technologies’ planetary gearbox. First shown off at Eurobike earlier this year, the new Orbit Drive is a bevel-gearbox electric motor system that is completely enclosed. The real trickery though, is the system’s ability to automatically vary the amount of input from the motor and rider for a given speed. This means that for a given speed you can choose how hard you want to pedal, or even set a preferred cadence and vary speed with your power input.

A direct drive between the bottom bracket and rear wheel can also be great news for mechanical reliability if engineered correctly. Driven Technologies claims a 10,000 mile maintenance-free period, which for most of us is at least 12 months of riding.

Automatic shifting is something that Shimano has dabbled with in its e-mountain bike divisions, but it still relies on changing sprockets, as opposed to a continuous gearing variation based on two inputs.

Regenerative braking

We’ve already looked at wireless braking, but there’s more in the world of electronics on bikes. Closed system drivetrains could provide designers with the ability to harness some of the gravitational potential energy and kinetic energy we work so hard for, in the form of regenerative braking. By having a direct link between a motor and rear wheel, a system such as Driven Technologies’ could be engineered to harness energy every time we need to slow down. We asked CTO of Driven Technologies, Jason Smith, about it. “Electric vehicle technology should be brought down to e-bikes, rather than starting with a traditional bicycle and adapting a motor to the existing chain drive,” he said.

To put the numbers into perspective, working with a 70% system efficiency, a 100kg system holds 0.02kWh of gravitational potential energy at the top of a 100m hill. Although harnessing this much energy wouldn’t go as far as to restore any meaningful level of charge to an e-bike battery, it would be enough to charge a powerful bike light twice over, which is well worth having.

It doesn’t just have to be done through drivetrains either, as French entrepreneur Adrien Lelièvre has shown with his Pi-Pop e-bike. His system uses a supercapacitor, which charges the bike when the going is easy. “The system gets charged when the ride is easy and when the bike brakes – thanks to engine braking – the energy is given back when needed,” he said.

A supercapacitor is capable of harvesting and releasing energy very quickly when needed, which allows the Pi-Pop bike to quickly provide a helping hand, for example at the start of a hill, but be deactivated, or even harvest energy, when pedalling along on the flat, or downhill.

The slight hang-up here is that the Pi-Pop bike weighs in at 20kg, which is hardly lightweight, but it is important to remember this system is currently fitted to a town-style e-bike

Adaptive dampers for gravel bikes

Matej Mohorič’s recent victory at the Gravel World Championships in Italy showed us that aerodynamics might just be overrated – on gravel at least – after he won on a new Merida Silex, the brand’s gravel explore bike. And that got us thinking, will SRAM’s suspension technology become mainstream in gravel racing?

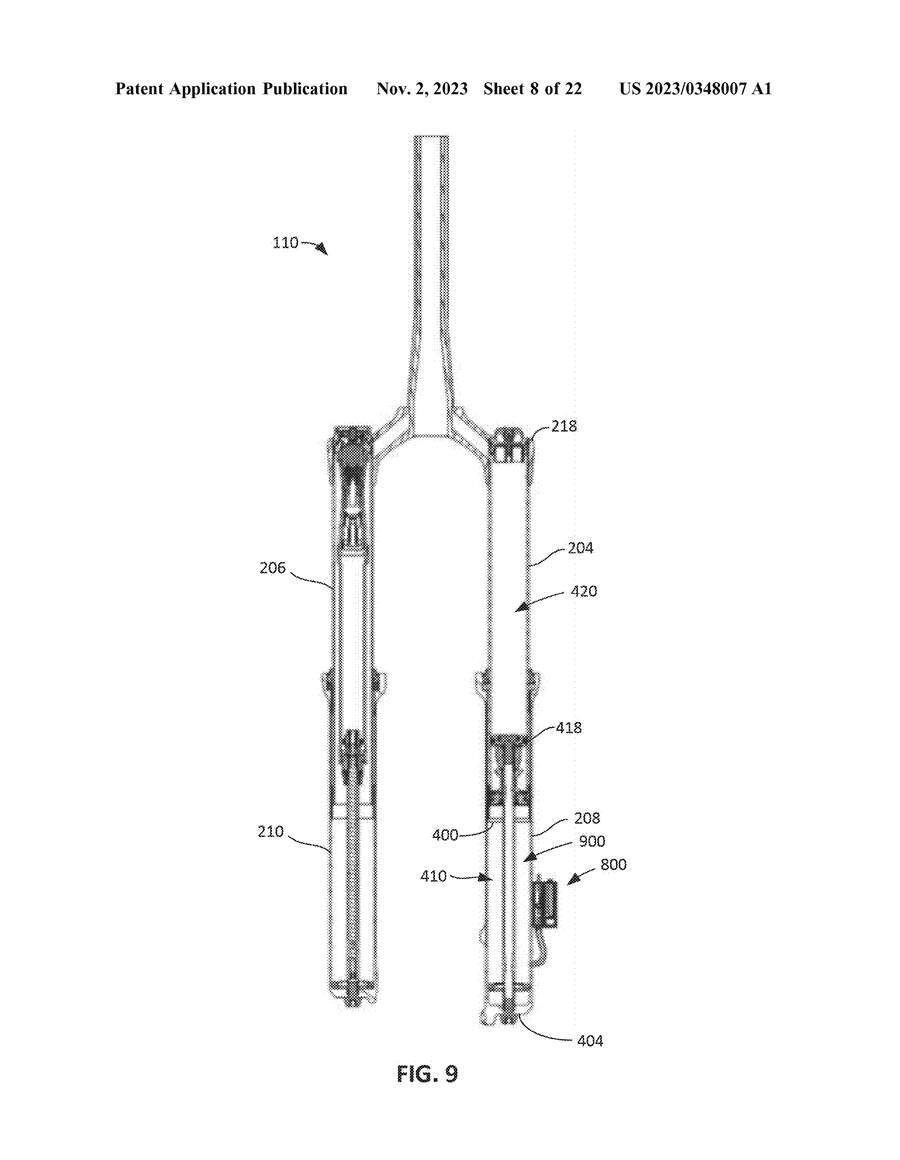

Back in 2016, SRAM released ShockWiz – a suspension sensor capable of analysing your suspension set-up, and communicating data to your smartphone, theoretically enabling you to make smarter suspension set-up decisions for your weight and riding. It’s fair to say that it hasn’t become mainstream, perhaps due to the £379 price tag, but a recent patent published on 2 November indicates that ShockWiz might be about to receive an overhaul.

While this may not spring to mind as a development for your next road bike, the applications for gravel riding are much further reaching. Many of us would undoubtedly benefit from some suspension on our gravel bike that doesn’t rely on our tyres being 50mm wide, but with suspension set-up being so sensitive to individual riders and terrain, it can be tricky to find the perfect balance. If SRAM does bring this platform to its next generation of gravel XPLR forks, we think that suspension forks in gravel racing could become a whole lot more popular.

Going further still, a system like this got us thinking about whether we might start to see automatic adaptive damper technology in gravel bikes in the coming years. In the automotive industry, they are commonplace, especially among vehicles aimed at multi-surface endeavours. If the technology could be made light enough, a system that goes beyond a simple fork lockout could make far better use of suspension systems, and pose a real benefit both for casual riders and gravel racers alike, even if that is looking to 2024 and beyond.

Progressive geometry

A brief delve into the geometry charts of different gravel bikes will show you that there is a huge variance in bike design. And we suspect 2024 will see more and more progressive framesets within the gravel genre. Mohorič’s and Kasia Newiadoma’s Worlds victories showed us that gravel racing remains popular with the pros and critical race-winning moments are down to more than just raw power.

Currently, there is a real divergence between gravel bikes using geometry that sits closer in line with mountain bikes, and those that are more road-derived. For example the Rondo MYLC, released back in 2022 features a 68° head angle – a number that would look at home on a mountain bike geometry chart. Meanwhile, Ridley’s Kanzo Fast aero gravel bike has a much more serious posture, with a 71.5° head angle.

More aggressive geometry tends to be found only on bikes designed for exploration, but in 2024 that may well change. The Traka gravel race for example, which I competed in back in March, had a number of decisive technical sections, as well as a 90km section of flat fast gravel, meaning the perfect bike for that event was something with the aero characteristics of something like the Ridley Kanzo, based on a much more aggressive geometry for maximising speeds on technical sections. We think bike designers will take note of Mohorič’s victory, and gravel bikes will continue to get more aggressive in line with the change in racing demands that have been so evident this year.

Fitness metrics at your fingertips

In every sport, athlete data is invaluable, and cycling is no exception. Just a decade ago, heart rate monitors and power meters weren’t must-use items in the pro scene, whereas now team staff are monitoring a whole host of live metrics to make tactical decisions and squeeze the best performances out of riders in training and racing.

Recent developments in what metrics we can easily harness have prompted us to wonder – just how much data could you have on your cycling computer in a year’s time?

Blood sugar levels are the latest, giving riders the ability to live monitor their numbers and assist them with fuelling a training session. This monitoring technology – pioneered by Supersapiens – is currently banned in competition, but would a different, less invasive technology, change this?

Afon Technology, based in Monmouthshire, Wales, is working on a needle-free real time glucose monitoring smartwatch that is due to start selling in 2024. They say their watch uses low-power RF/microwave technology to track and record changes in blood glucose levels in real time. It’s possible that the same technology could be incorporated into other smartwatches which would be almost impossible for the UCI to ban.

Could technology ruin bike racing?

In any sport, the use and harvesting of data must be carefully managed to keep both viewer excitement and technological development in equilibrium. I would in fact go as far as to say that there is a direct correlation between the amount of data analysed and the viewing quality of a given sport.

The UCI’s Lugano Charter was the basis on which all its technical regulations are created with the aim of ensuring that bike racing is always about the athlete, and not the bike or the equipment they ride. Ironically the gains made in the time since its release in 1996 have been greater than all those before as they have come in the form of performance measuring, nutrition, aerodynamics and more – and all supported by new tech, from training software to materials development.

It’s unrealistic to think progress can ever be halted in such a tech reliant sport but the UCI will have to significantly up its game if it’s to keep abreast of endless industry developments to ensure they enhance rather than impair the sport.