A cartridge of instant film is really both film and “darkroom” in one – and a recent tour of Polaroid’s only film factory sheds light on how the medium works. In a video recently shared to the brand’s YouTube channel, Polaroid shared a behind-the-scenes look at how the film is made – and in the process shared some insight as to why modern Polaroid film isn’t the same as the historic film crafted decades ago.

Polaroid’s film factory is located in Enschede, Netherlands. The assembly plant is the only remaining place where packs of Polaroid instant film are made. While the company also produces the sheets of negative and positive film material in Germany, the Netherlands factory is the only remaining place where genuine Polaroid film is still created, after the Impossible Project group sought to save the classic film type, eventually becoming part of the Polaroid company itself.

The positive and negative film sheets arrive at the Netherlands factory in bulk sheets. Polaroid explains that each positive sheet has six layers and two coatings while the negative sheet has 12 layers that are each thinner than a strand of hair. The negative sheet needs to be handled in complete darkness once the material is coated, which means the Polaroid factory workers in this part of the plant wear night vision goggles.

But, a Polaroid cartridge is both film and darkroom in one, and the components to the film responsible for developing the image before it is injected from the camera play a key role. In a pack of Polaroid film, a developer paste sits inside of a small pod (that’s one of the reasons why the classic Polaroid frame has a wider white edge on the bottom).

After the image is taken, rollers inside the camera squeeze out this developer paste over the image, applying the chemicals evenly to the image, allowing the image to be developed – and thus no longer light sensitive – as it is spit out of the camera. Those rollers squeezing out the developer paste is also why you don’t actually need to shake a Polaroid picture.

In the video, Polaroid explains that each batch can be slightly different due to factors like weather and humidity. To help keep the film more consistent, the developer paste undergoes quality control testing. The paste is then developed in large batches inside the reactor room, a machine that weighs and mixes the paste, with the largest reactor capable of making about 800L of paste, which is enough to fill 80,000 packs of film. That paste is then filled into the pods that will later be attached to the bottom of each Polaroid frame.

In another part of the factory, an injection molding machine melts plastic granules to make the cassette that holds the pack of film together and keeps the light sensitive materials in darkness until the shutter on the camera is pressed.

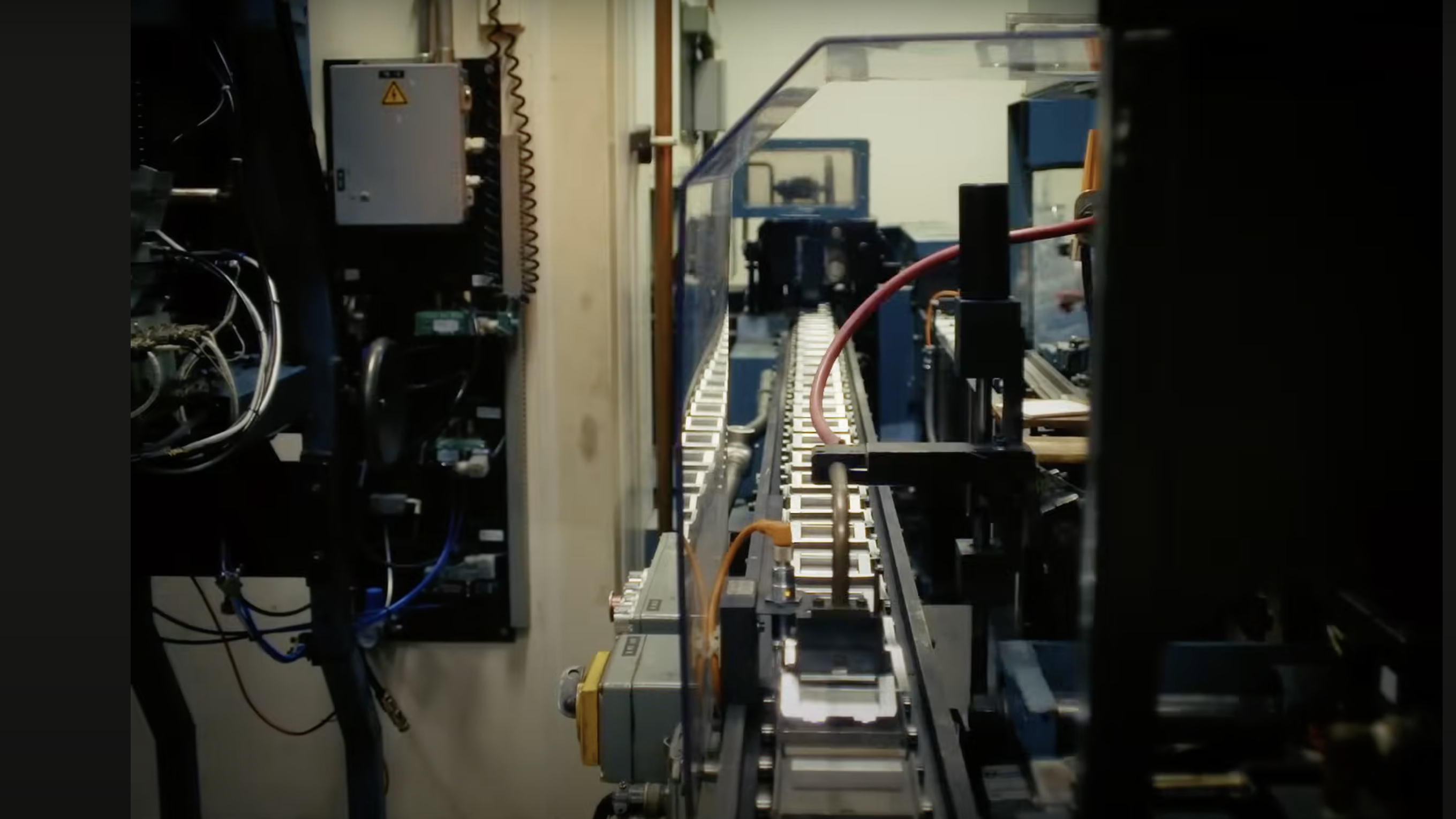

All those different components meet in the assembly room, where eight sheets of film are wrapped with that classic white border, outfitted with a developing pod, and placed inside the light tight cassette with a protective cover. The film packs are then sealed and packaged for shipping.

The Polaroid factory’s colorful history and rescue at the hands of The Impossible Project was the subject of a documentary, but the tour gives photographers insight into what actually goes into making instant film. The entire process uses about 30 machines, many of which are part of the original factory and no longer made, where troubleshooting any issues requires looking at the manual on microfiche.

But, towards the end of the video, Andrew Billen, Senior Vice President of Film Manufacturing, also shares some insight into why modern Polaroid film isn’t quite the same as the film from decades before. Billen explained that the company does still have the "recipe" to make the original formula. But, manufacturing standards have changed, with the old way of making the film and chemicals not as environmentally friendly. The other factor is that some of the chemicals used in classic Polaroid film were custom designed specifically for the instant film.

“The majority of the chemicals in this product are made exclusive for us,” Billen explains in the video. “We’ve got to design chemistry… People expect this product to be, ‘yeah it’s not as good as the old Polaroid.’ Yeah, it isn’t. But we’ll get there. It just takes a lot of time. It’s just never a dull moment. Insanely complex product to make, extremely frustrating but so mega rewarding.”

The behind the scenes look at the Polaroid factory also offers other interesting tidbits – including an employee who has worked there since 1973 and even has a picture of himself on his first day of work which, naturally, was taken with a Polaroid. The video also notes some of the differences between film types, including that some types of film cassettes only need a spring to eject the film while others actually have a battery inside the pack.

You may also like

Browse the best instant film cameras, or learn the difference between Instax vs. Polaroid instant film or the different instant film sizes.