There’s this weird thing about the entrepreneurial spirit and trying to create jobs from a new idea: It takes intense work and focus but also patience, qualities hard to find in equal measure.

On the Near West Side, within blocks of each other, are examples of two such operations seeing results from its investments of labor, thought and capital. They will be part of an innovation economy taking root in what was Chicago’s old meatpacking and produce district.

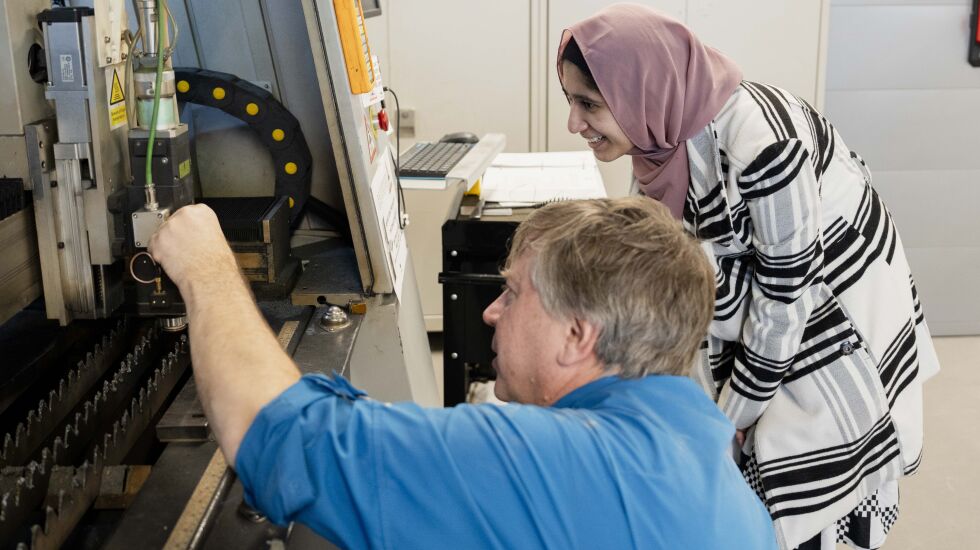

They are mHUB, a nonprofit incubator for young ventures in high-tech manufacturing, and NanoGraf, a private company developing for the U.S. military lithium-ion batteries that are more powerful, lighter and last longer than others. Both have expanded space to allow for more projects, and both expect to add jobs within the next two years.

In mHUB’s case, it will cut the ribbon Tuesday on its new home. It has taken over a nearly century-old building with a clock tower at 240 N. Ashland Ave. and given it a new address to suit its purposes, 1623 W. Fulton St.

The 80,000 square feet will afford mHUB more space for prototyping and testing compared with its former base on Chicago Avenue.

The acquisition and build-out costs total $50 million, said mHUB CEO and co-founder Haven Allen. He said mHUB is adding companies and startups to its active roster of clients and hopes its own workforce — 33 employees — will grow 50% by 2026.

It works in the field of hardtech — research in engineering and software applied to physical products. Examples of companies that launched with mHUB’s help are NuCurrent, working on wireless power sources, and Sabanto, developing equipment to automate farming.

Allen said hardtech is one business segment that hasn’t lacked for venture capital through the pandemic and concerns about a recession and rising costs. He said the more than 500 startups and small businesses mHUB has supported since its beginning in 2017 tend to set up shop in Chicago.

“I think we’re just getting started,” he said.

The organization is close to other tech-oriented office and lab sites planned in Fulton Market by the Chan Zuckerberg Initiative and developers Sterling Bay and Trammell Crow, among others.

Allen said the activity will draw tech-focused employees who crave the city lights.

“People want to be where they can live, work and play,” he said.

When the mHUB project was announced earlier this year, it caused a stir from its level of taxpayer support, including $17.6 million from the city in tax increment financing. A former city planning commissioner called the request “eye-popping,” even though he supported it. The project also got a $15.5 million tax-exempt bond issued by the state.

Allen said mHUB got the backing because of its exemplary record. “Our return on capital has been 2,000 times the public investment,” he said.

NanoGraf dates from 2012 as a Northwestern University startup and later outgrew its incubator space at the Illinois Institute of Technology. On Dec. 1, it opened its new 17,000-square-foot space at 400 N. Noble St.

The company has a $10 million federal contract for its promise to onshore battery technology, meaning to keep it in the U.S. The military has taken notice and gave NanoGraf a $1.65 million contract. Within days of the office opening, NanoGraf announced an $8 million deal with the U.S. Army.

“The military is our beachhead market,” said CEO Francis Wang. He said the continued ramp-up of work should allow the company to double its count of full-time workers to 60 in two years.

Wang said he hopes the proprietary technology, which increases batteries’ energy density by 20%, will find applications in power tools, electric cars, medical devices and other consumer products.

He said the company practices “stepwise growth,” a conservative strategy in the spendthrift world of tech.

“Our strategy has been to go slow and try to become profitable in the near term,” he said. Wang said he foresees that happening within the next 18 months, buoyed by those federal contracts.

In February, NanoGraf said it raised $65 million in Series B, or second round, funding from private investors.

Michael Fassnacht, president and CEO of the economic development group World Business Chicago, has followed mHUB and NanoGraf and likes what he sees. He said manufacturers in the Chicago area can source half their material from within the region, a key advantage.

“The Chicagoland region stands at the forefront of manufacturing diversity and innovation in the United States,” Fassnacht said.

For Wang, the Near West Side is the right spot for growth. He mentioned the investments in Illinois by Gotion, Lion Electric and Rivian, all related to electric vehicles.

“The Rust Belt is becoming the Battery Belt,” he said.

If that’s a new reputation headed Chicago’s way, we’ll take it.