Following our recent lab test to determine which road bike tyres are the fastest, we returned to the Silverstone Sports Engineering Hub to undertake a similar test on a whole host of gravel tyres.

While road bike tyres have a large impact on the ride, on gravel the impact has the potential to be even greater. The tyres are bigger, you need to choose the right tread in order to maintain grip over what can be a wide range of surfaces without it holding you back unduly, and as the speeds are generally lower (resulting in a lessened aerodynamic impact) the rolling resistance has a greater sway on your overall performance.

Aerodynamics has started to play a major part in top end gravel racing, with aero gravel bikes, wheels, and other tech, but getting your tyre setup right can, as we will see, have significant wattage implications.

Unlike road tyres, however, gravel tyres are often sold in various options - primarily confined to width and casing - making direct comparison between two models harder. One brand’s general-purpose casing may be more akin to another brand’s racy option, and you might also be torn between one tyre that only comes in a 40c, and another that only comes in a 45c.

With this in mind, instead of simply spending the day mounting 30 or so of the best gravel tyres from various manufacturers and seeing which was the fastest in the lab we decided to be a little more scientific and have selected a suite of tyres so that we can find the effect of changing the tyre width, the tyre tread, and the tyre casing in isolation.

The tyres on test are from Vittoria, Pirelli, and Panaracer - with no affiliation or bias - and our hope is that armed with the results below you can make a more informed decision when choosing any gravel tyre from any brand.

The absolute wattage differences between the tyres on test will, of course, be specific to the actual tyres on test, but they should give you a very good indication of what’s on the table in terms of performance gains, when making similar changes with other brands and models too.

Other Cyclingnews lab tests

- Lab tested: Which road bike tyres are the fastest?

- Wind tunnel tested: 10 road bike wheelsets

- Wind tunnel tested: 23 road bike helmets

- Wind tunnel tested: 11 superbikes

- Lab tested: 15 bib shorts pressure-mapped

- Wind tunnel tested: Aero wheels vs basic wheels

Before we get into the thick of it, a quick interlude to say that this feature is not sponsored. Cube loaned a bicycle for us to use - a Nuroad C:62 SLT - but had no say in the test setup or results in any way. We paid the normal commercial rate for our test access and bought or borrowed everything used in the test. This content was made possible solely and entirely by our paying subscribers.

The tyres

Initially our inclination was to undertake the gravel test in a similar way to our road bike tyres test, to the point we had already called in a huge suite of 40c-ish gravel tyres, from almost-slick race options through to mud-specific, tractor-like beasts. On reflection, we didn’t feel this would have been overly useful.

First and foremost our inclination is that most people choose a gravel tyre based on the grip level they require. There’s little point finding out that the Hutchinson Caracal Race is faster than a Vittoria Terreno Wet for example, as if you fitted the former in the winter you may go very fast for a short time but could well come to a complete standstill the moment you encounter any muck.

Instead, taking a look at the market as a whole, we aimed to answer three key questions:

- How much faster/slower are wider gravel tyres?

- How much faster/slower are knobbly gravel tyres compared to slick options?

- How much difference does the tyre casing make?

Tyre width

Gravel tyres, like road bike tyres, have become wider over the years. Not so long ago it wasn’t uncommon to see gravel bikes specced with 35c or 38c tyres. The brief flirtation the market had with smaller diameter 650b wheels did allow for much larger tyres, but the general trend is now back to 700c, and even 40c tyres are on the narrow side.

At the very top level of the gravel race scene, we have riders like Dylan Johnson flying the flag for truly enormous tyres, himself running 2.2in mountain bike tyres on his gravel race bike on the insistence that they are faster.

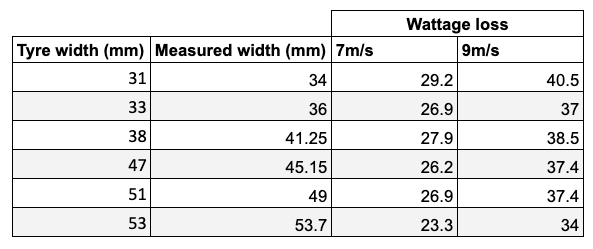

In order to test the impact that changing tyre width has on rolling resistance we needed to find a tyre model that came in the greatest number of widths, while keeping the tread and construction of the tyre the same. The Vittoria Terreno Dry was selected for this test, with a 700c diameter tyre in 31c, 33c, 38c, 47c, 2.0in (50mm), and 2.1in (53mm).

Each size option uses the brand’s ‘Gravel Endurance’ casing, and the central tread is a semi-slick affair, consisting of a series of very closely spaced hexagons with more prominent side knobs.

Tyre tread

In order to assess the impact of tyre tread - that being moving from an essentially slick tyre through intermediate options to a very knobbly option - we tried to find an option that would have the same construction and width, with only the tread changing for as many tread options as possible. Sadly the reality is that tyres designed for soft, muddy, slippery, or really rocky conditions tend to have different constructions than those designed for lovely hardpack and smooth gravel.

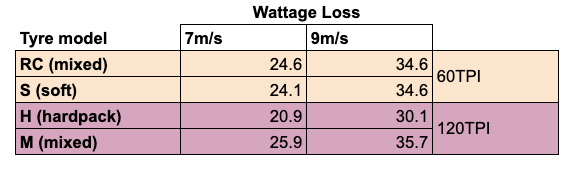

Despite this we settled on the Pirelli Cinturato gravel tyre range. The four options from the range that we tested, those being the ‘H’ (hardpack), the ‘M’ (mixed terrain), the ‘S’ (soft), and the ‘RC’ (an option that’s somewhere between the H and M in terms of tread).

The S and RC options use a more sturdy 60TPI (threads per inch) casing, while the H and M options use a more supple 120TPI carcass, meaning we have two separate studies into what happens when you go from a smoother (the RC and the H) to a more knobbly tyre (the M and the S). While we won’t be able to have a true trend line with four data points, the upside is that we will be able to indicate whether the differences are greater, or roughly the same with different casings.

Tyre casing

Tyre casing pertains to the material construction of the tyre itself, rather than the width or the tread. Manufacturing a tyre is actually a lot more akin to the textiles industry than you might expect. Beneath the rubber tread running from bead to bead is a rubber-impregnated textile casing, ignoring any extra puncture protection strips and the like. How supple this casing is is primarily down to the thread count, or the TPI rating. Racy tyres will often have a 120 TPI casing, while more endurance-focused ones will be 60 TPI or lower. Some cyclocross tyres can be up as high as 340TPI, but there is a corresponding increase in fragility.

Suppler tyres deform more easily over the road or gravel surface, and so have a lower rolling resistance. How much this affects things is what we aimed to find out, and so we needed to find a tyre model that exists in the same width and tread pattern, but with multiple casing options.

Initially, René Herse slicks were selected, as they come in four casing options, but getting hold of them in time proved difficult. Fortunately, the latest Panaracer Gravelking X1 comes in three casing options, a 'Standard', a 'Plus' option that prioritises puncture resistance, and an 'R-Line' option with a more supple casing for the prioritisation of speed.

The tests

Testing took place on the Silverstone Sports Engineering Hub’s pedalling efficiency rig. SSEH has a rolling resistance rig, but in the same way as for our recent road bike tyres lab test, we opted for pedalling efficiency, with an actual rider and a larger drum, to get more real-world applicable data.

The rider (Josh, once again), was atop the bike. The front wheel is mounted in place in a flexible bracket, and the rear wheel rests on a large (2m diameter) drum, with a simulated tarmac surface. Josh rides at two set velocities, and his power input is measured with a set of Body Rocket pedals 100 times per second. The drum then measures the power output at the same frequency, with the difference between the two values being the total system power loss.

There will be drivetrain losses, but they are controlled over the course of the tests as the drivetrain remains the same throughout the day. As such, any differences in power loss between tests are a result of changing the tyre.

Naturally, the power loss is for a single tyre and will be reported as such. Later in this feature, I will double it to account for a pair of tyres. This will be made clear.

The efficiency rig does have a series of surface options, those being a simulated tarmac surface, and two different roughnesses: settes and cobbles. It might have been an easy choice to opt for cobbles as a pseudo-gravel analogy, and there is certainly merit in this decision, however in an effort to more effectively isolate just the behaviours of the tyres we opted for the tarmac surface, on which consistent pedalling technique is more achievable. Gravel riding takes in such a variety of surfaces that we also didn’t think opting for one cobbled surface and extrapolating that for all gravel was the most useful data we could get.

Moreover, there is a huge portion of the retarding forces on a rider on gravel that comes not from the deformation of the tyre but from the deformation of the gravel surface itself (think how hard riding through sand is compared to, say, a compact hardpack train), and while the cobbles effectively simulate extreme surface roughness and the effects therein on the tyre, it does nothing to simulate the shifting substrate beneath one’s wheels and the dynamic interplay between the two.

On the same day we did a separate study into road tyres across multiple surfaces, the results of which will be published in due course, though suffice it to say there is certainly scope for further study in this area in the world of wider gravel tyres.

Present on the day

- Me - Will Jones - For my part I spent the day outside changing tyres every ten minutes, as well as capturing photos of everything.

- Josh Croxton - The legs needed to pedal the setup consistently.

- Tom Wieckowski - Ex-professional mechanic meticulously recording everything that could be recorded.

- Sam Gupta - Photo duty and video coordination.

- The team of engineers from SSE Hub.

Protocol

Our road tyre tests operated at a two speeds - 9m/s and 11m/s, or 32.4km/h and 39.6km/h - that we deemed a little unrepresentative of gravel riding. As such we conducted our tests at 7m/s and 9m/s, or 25.2km/h and 32.4km/h. A round integer is needed to give Josh something easier to hit, and these speeds represent what could reasonably be called fast amateur speeds and something more akin to race pace.

Each test run was completed twice, so each tyre was run at 7m/s then 9m/s, and then at 7m/s and 9m/s again, and Josh dismounted and remounted the bike between each pair of tests to replicate - and thus control for - any small differences in position that could occur between swapping tyres.

Each run at each speed lasted 60 seconds, after an initial warm-up period, and the data was available in real-time so that if anything looked wildly out of the bounds of expectation we were able to stop, check, and repeat if necessary.

Standardisations

Each tyre on the test was set up tubeless with an identical volume of Muc-Off sealant. Based on our experience we have found that, while it may be insufficient for riding in the real world, 30ml of sealant is sufficient to seal a tyre effectively. There is certainly a case to be made for scaling the volume of sealant with the tyre size, but we opted for our approach to control one more variable, and better isolate the behaviours of the tyres themselves.

Each tyre was set up to a pressure determined using SRAM’s online pressure calculator, inflated using a digital track pump and verified by a standalone tyre pressure gauge. Both the Panaracer tyre casing test cohort and the Pirelli models were all 40c in width, so an identical pressure was used for a great many of the tyres on test.

Given that system weight has an impact on the contact patch, which in turn has an impact on rolling resistance, Josh’s weight was also controlled throughout the day. In simple terms, we weighed him and topped him up with water and food as necessary to maintain the correct system weight. The weight he lost over the short duration of each test in perspiration was deemed to have an utterly negligible impact on the results. Josh's position on the bike's handlebars and saddle was also noted and replicated for each test.

As mentioned above, the velocity of each test was controlled and maintained consistent throughout. Any tests where the velocity varied outside of acceptable limits (+/-0.1m/s) the test could be stopped and repeated, but fortunately, this didn’t occur. As well as controlling for velocity, the test bike was kept in the same gear throughout in order that cadence, drivetrain efficiency, cross-chaining, and pedalling smoothness could also be controlled.

The testing took place in a temperature-controlled room, and the temperature of each tyre was monitored throughout the test. While the tyres were changed outside to avoid mess, they only spent a short duration outside to minimise any cooling, and were given a re-acclimatisation period to warm back up to ambient temperature in the test room prior to being tested.

The bike, a Cube NuRoad C:62 SLT, was consistent throughout the test, with an identical position used for the duration. Each tyre was mounted on an identical rim, a Hunt 40 Carbon Gravel Race with hooked sidewalls and a 25mm internal width. While the weight distribution will not have been exactly 50:50 front:rear, for the purposes of this article we are going to do a simple doubling calculation when discussing a pair of tyres.

The surface, as mentioned previously, was also controlled for. It should be noted that, as with the road tyre test, the use of a drum rather than a perfectly flat surface will lead to slightly higher wattage losses as the contact patch is marginally larger. Opting as we did for the larger 2m diameter drum on the pedalling efficiency rig alleviates this to a great degree versus the smaller diameter rolling resistance drum.

On a similar note, the drum effect will have a slightly greater impact on knobbly tyres, as it effectively pushes the knobs further in than a flat surface would, resulting in greater tyre deformation. This is only really pertinent when discussing the difference a change in tread makes, and will be discussed further in the relevant section later.

Confidence level

Given each tyre was tested at each speed twice, we have a lot of data showing the variability from one test to the next. Taking the average variability for each speed we are left with a 0.64-watt variability for the 0.7m/s velocity, and a 0.65-watt variability at 9m/s.

Given our day was broken into segmented tests that lasted around an hour each, there was no need to perform a start-of-day and end-of-day repeat to track the variance across the day.

Additional notes and disclaimers

As with our road tyres lab test, the aim here isn’t to try and produce an absolute figure for each tyre on test in terms of wattage losses, but instead to create a test that most accurately shows the gains or losses that are on the table when choosing one gravel tyre setup over another. Rolling resistance is just one of a number of factors that go into the ideal tyre setup, including grip, puncture resistance, aerodynamics, weight and comfort, all of which have an impact on overall performance.

Results

Results

In general, our suspicion (based on our own experiences) is that one tends to pick a tyre first based on the tread, then the size, then the casing options. That, then, is the order we will tackle the results.

Results: Changing tread

Our hypothesis is relatively simple, based on the received wisdom that knobbly tyres have a greater rolling resistance than slicker options. To test this we ran two 40c tyres with a 60TPI casing, and then two more 40c tyres with a 120TPI casing. Within each, we had a knobbly version and a slicker version.

In this case, the slicker options are the Pirelli Cinturato Gravel RC (60TPI) and the Pirelli Cinturato Gravel H (120TPI), while the knobbly pair are the Pirelli Cinturato Gravel S (60TPI) and the Pirelli Cinturato Gravel M (120TPI).

The results show a bit of a mixed bag. Starting with the pair of tyres with a 60TPI casing, moving from the RC to the S effectively leads to no tangible change in rolling resistance, even when doubled to a pair of tyres. AT 9m/s the wattage losses are actually identical, and at 7m/s the average wattage losses are only 0.5 watts different, or a single watt over a pair of tyres. I should note that while the Cinturato Gravel S is nominally more knobbly than the RC, the difference in the tread, in this case, is far less stark than the 120TPI casing.

Moving up to the 120TPI pair, we can see a much greater difference in results, of around five watts per tyre at both speeds. At 7m/s the difference is 5 watts, and at 9m/s this increases to 5.6 watts, leading to losses for a pair of tyres of 10 watts or 11.2 watts respectively. The difference in the tread in the case of this pair of tyres is much starker, with the H having a relatively slick centre, and the M having large, well-spaced and tall knobs.

What can we conclude from these results, if anything? It could be argued that for tyres of relatively similar tread design, the rolling resistance will be similar, but there is enough visual difference between the RC and the S to doubt this as a conclusion.

My hypothesis is instead that for stiffer casings - those of 60TPI and even lower - the effect of the casing is going to be the dominant factor controlling the overall rolling resistance. And as such there is little penalty for opting for the more grippy option if you are choosing an endurance-oriented tyre.

Once you move into the realm of more supple tyres - those of 120TPI or more - my conclusion is that here the tyre carcass is having a more balanced impact on the overall rolling resistance figure, and ‘allows’ (for want of a better word) the tread to tangibly impact proceedings.

In short, if you’re choosing stiff, resistant tyres and you're on the fence between two tread types, then just opt for the more grippy option, whereas if you’re choosing a race-cased pair of tyres and you're weighing up your tread options, you should pick your tread more carefully, balancing the performance aspects of grip and cornering against rolling resistance.

This does somewhat have implications for races like Unbound, where our experience in talking to the pros is that they tend to prioritise puncture resistance over supple casing due to the sharp flint gravel. Further study is of course necessary, but it could be that the pros could, in instances like this, be running far more knobbly tyres than we see them doing with little or no detrimental impact and improved grip and traction in cornering and in muddy conditions.

Results: Changing width

You’ve decided what sort of tread you want, but now you have to decide what width to choose. Received wisdom has for decades been that narrower tyres are faster, due to a smaller contact patch, but just because something feels fast doesn’t actually make it fast. Narrower tyres mean higher pressures and more vibration transferred to the rider, which results in things feeling fast, but is this borne out by the data?

To put this to the test we tested the Vittoria Terreno Dry in 31c, 33c, 38c, 47c, 2.0in (50mm), and 2.1in (53mm). The tyres each had an identical 120TPI casing, and a semi-slick tread, so based on our inferences from the casing study above, we can say that the tread is slick enough and the casing supple enough that we can hopefully isolate just the effect of changing width.

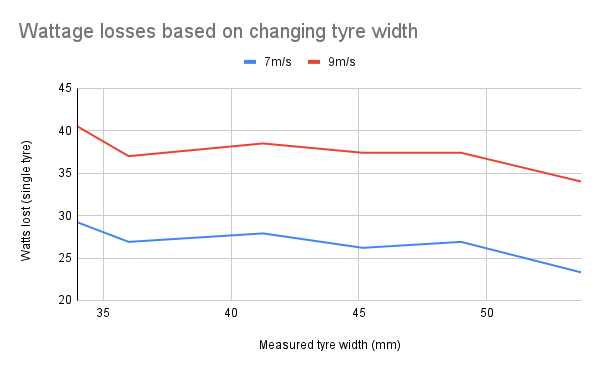

Graphing the results shows that, in general, wider tyres are faster. There are some fluctuations in the trend line, most notably with the 33c (measured 36mm) having a noticeably lower rolling resistance than the 31c and 38c options. I suspect that despite Vittoria marketing them as the same, the construction might be slightly different by dint of its cyclo-cross intentions.

Even if we don’t take the 33c option out, the fastest tyre width at both 7m/s and 9m/s was the giant 2.1” option, with a saving of 5.9 watts per tyre at 7m/s and 6.5 watts per tyre at 9m/s, comparing the 31c to the 2.1”. That’s an 11.8-watt difference for a pair, or 13 watts at 9m/s for two tyres across the whole range.

A 31c tyre is effectively a road width nowadays, and so we suspect there are precisely none of you mulling over whether to choose a 31mm or a 53mm tyre for your gravel bike. Taking a more likely scenario, what do you stand to gain by swapping from the normal 40c width that many gravel bikes come equipped with nowadays (or 38c in this case, as it’s our nearest equivalent) to a 2.1in tyre? At 7m/s you’d save 4.6 watts, or 9.2 watts a pair, and at 9m/s you’d save 4.5 watts, or 9 watts for a pair.

This is very against the received wisdom, but the data doesn’t lie: Wider tyres are faster, and noticeably so. While we didn’t repeat the same test on the cobbles for reasons already outlined, we have data that suggests that when you introduce surface roughness, the differences between tyre widths are greatly exaggerated, so while you may gain 9 watts for a pair on buttery smooth gravel, once things turn bumpy you stand to save an awful lot more.

It should also be noted that this is only taking into account the measurable rolling resistance, and does not account for any increases in aerodynamic drag that may come from the increased frontal area, and likewise it does not account for the increase in system weight. In our more realistic 40c to 2.1in scenario, there is a weight penalty of 68g/2.3oz per tyre, or 136g/4.8oz the pair, not accounting for any increases in sealant volume which will further increase weight.

The impact of system weight on overall performance is going to depend very much on the parcours in question, and as such it isn’t hugely useful for us to create a random hypothetical scenario to illustrate how many watts 136g will cost you.

In aerodynamic terms, while we did not take these setups into the wind tunnel ourselves we are able to draw on the work of others. Dylan Johnson, professional gravel racer and YouTuber, also recently undertook his own tyre testing at the SSE Hub, and while his tests involved different parameters, speeds, and setups to ours, he did also put his own race bike in the wind tunnel with varying tyre sizes. At 36km/h he found a 5.5 watt penalty moving from a 40mm to a 50mm Pirelli Cinturato H, but was also at pains to point out that his tests of the 2.2in (56mm) Continental RaceKing actually tested faster than the 50mm Pirellis, perhaps due to the sidewall texture, at least showing there is more to aerodynamics than simple frontal area calculations.

Cumulatively then, accounting for choosing a faster tread and the fastest width, we are currently looking at a total rolling resistance difference of around 20 watts on a smooth surface, and likely more on a rough one, moving from a narrower knobbly tyre to a larger, more slick option.

Results: Changing casing

Casing concerns the construction of the tyre carcass rather than the tread. It’s likely the last thing you’d consider once you’ve settled on a tread pattern and the width. Many brands offer the same tread in the same width, with multiple casing options, often with names like ‘endurance’ or ‘race’ to denote how supple they are.

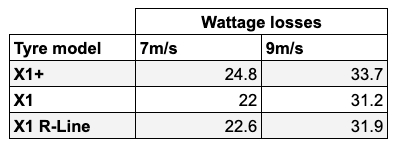

To assess how much impact the tyre casing has on the rolling resistance, we tested a Panaracer GravelKing X1 in three iterations: The standard X1 with a 120TPI casing, the X1+, which features a 120TPI casing but additional ‘TuffTex+’ puncture protection from bead to bead, and the X1 R-Line, which also features a 120TPI casing, but with reduced puncture protection resulting in a much more supple carcass.

I do appreciate that each tyre does nominally have a 120TPI casing, but in the hand it’s clear they are vastly different in terms of stiffness. The X1+ holds its shape and is relatively tricky to mount onto a rim, while the X1 R-Line is beautifully flexible.

The results here are a little inconclusive sadly, but data is data nonetheless. The standard X1 and the X1 R-Line tested very similarly, with the R-Line actually coming out slightly slower. Nevertheless, fitting the standard X1 instead of the X1 R-Line will save you 2.8 watts at 7km/h, or 2.5 watts at 9m/s, or 5.6 watts and 5 watts respectively for a pair.

While the treads are different, we can also draw some conclusions by comparing the two mixed-terrain Pirelli options from the tread study. The 120TPI Cinturato Gravel M actually came out slower at both speeds than the even more knobbly Cinturato Gravel S.

In short, from our dataset, it appears that casing, at least the TPI figure, doesn’t seem to have a predictable outcome on tyre performance. From personal experience, I can say that you can absolutely feel the difference between a super supple tyre and a rigid one, but the problem comes with inconsistent notation.

A 120 TPI casing could be a single ply of 120 threads per inch fabric, but it could equally refer to a double layer of 60TPI, which would result in a stiffer, higher rolling resistance tyre than a single-ply 60TPI option.

In short, in terms of useful consumer advice, it’s not prudent to compare tyre casings based on simple TPI figures. The construction will vary from brand to brand, and as well as the carcass, things like additional puncture protection strips will come into play too. Even within a brand, the construction from model to model may vary to the point that accounting for differences in casing as a performance indicator becomes impossible.

In short, from our studies, you could be looking at something in the region of 5 watts difference in terms of performance if you opt for the more racy pair of tyre options of the same model from the same manufacturer.

This also raises the puncture protection debate. For races like Unbound, where punctures have the potential to be incredibly frequent and race-ruining, losing 5 watts total for a better chance of staying in the race seems like an absolute no-brainer.

Takeaways

What are our learnings then, to help you make the most informed decision when it comes to speccing not just your gravel tyres, but potentially your next gravel bike?

I think first and foremost the key takeaway is that wider gravel tyres are faster, at least in terms of rolling resistance. We don’t yet have the aerodynamic data to contribute to the overall picture, but from what we can see there is a definite benefit to going wider, and it is likely based on other data sources we’ve seen that the benefits are even greater on rough surfaces than they are on smooth ones.

There is going to be an aerodynamic component to this, but again it seems that even for an extreme scenario of a 2.1in tyre, the wattage losses in terms of aerodynamics will be outweighed by the rolling resistance gains versus a 38c tyre even on smooth surfaces at moderately fast speeds.

At more reasonable speeds - below 30km/h, so essentially everything below top-end gravel racing - the gains will be even greater, as the impact of aerodynamics, while still important, will play a lesser role in the overall picture than it does at fast road riding speeds. Essentially, as a rule, you should fit the widest tyres you can, and if you’re buying a new bike then the maximum tyre clearance should be a key consideration. Not only will you be faster in almost all scenarios, but you will be more comfortable, and have better grip too.

When it comes to tread, the differences are likely to depend just as much on the tyre construction as they do the actual tread pattern. When it comes to stiff, puncture-resistant tyres the differences between a knobbly and a relatively smooth gravel tyre appear to be minimal, so you can opt for the more grippy option. With more supple tyres you will see some benefits to choosing a smoother tread, but do please remember, if you cannot corner or put the power down when the moment comes, then any wattage differences will be erased in an instant.

Finally to tyre construction. In my own, and my colleagues’ experiences too, more supple tyres are faster, but you cannot simply use the TPI figure as a direct proxy for the suppleness. Instead, you’ll be better off using the findings here to inform your decision if you are presented with two options for a tyre you want to buy, usually called something like 'race' and 'endurance'. The former could be around 5 watts a pair faster, and will be more comfortable and likely have better grip, but with a corresponding reduction in puncture resistance. Another way to frame it would be ‘is 5 watts worth me risking a race-ending puncture?’

How do gravel tyres compare to other upgrades?

Finally, it’s worth contextualising the impact of optimising your tyre strategy against other gains. We are fortunate in that we’ve tested bikes, wheels, and helmets in the wind tunnel, and we’ve also tested a load of road tyres.

Comparing gravel tyres to road tyres in terms of our data is tricky. Swapping from one of the slowest (but still decidedly very premium) Vittoria Corsa Pro Control to a Continental GP5000S TR would win you over just under 20 watts, but that’s comparing one model of road tyre to another with a totally different construction. There is every chance that comparing two equally sized gravel tyres would result in an even greater wattage difference, and this is a test we may well undertake in the fullness of time for added context.

What we can say is that optimising your gravel tyres, by which I mean choosing the fastest width, tread, and casing, could potentially net you something in the realm of 25 watts at the upper limit.

This is roughly the same as swapping from one of the slowest road tyres we tested to one of the fastest, and about the same as what you’d gain by swapping from a decade-old Trek Emonda ALR with box section alloy rims to a Factor Ostro VAM aero bike at a cost of £10,000/$11,000.

It’s greater in terms of performance gains than, say, swapping from box section wheels to a set of 50-60mm deep rims, which is worth about 7-10 watts even at faster speeds than we tested here.

As per road tyres, but even more so given the increased gains when the surface is rough, the benefits of optimising your tyres are greater the slower you ride. Rolling resistance is linear with speed, while aerodynamics is a square relationship, so at lower speeds, the rolling resistance is going to be a greater proportion of your overall retarding force equation.

Finally, it’s always worth remembering that there’s nothing slower than puncturing. Yes, fitting the most supple tyres you can for off-road riding will probably make you faster, but it’ll all be for nothing if you’re forever having to dig out the Dynaplug or the spare tube. The chances of punctures can be much greater off-road, so please bear this in mind and view the data presented here in the context of a holistic performance outlook.

Thank yous

Firstly thank you to all the brands that provided tyres for this test, with no obligation to the result. Without your trust that we'd do a fair job this wouldn't be possible.

Further thanks also must go to Hunt for the loan of a load of identical wheels, to Cube for sending us a gravel bike with the capability to fit some very large tyres, and to Muc-Off for all we'd need to spend a whole day swapping tyres and setting them up tubeless.

The team at the Silverstone Sports Engineering Hub were ever helpful, patient, and professional, and without their input on protocol and their willingness to power through a full day of testing, we wouldn't have the dataset that we have been able to share with you.

Josh once again put in a huge shift on the bike itself. Frankly, without this metronomic behaviour hour after hour, we wouldn't get nearly as much done.

Sam and Tom, without their help with the tyre setup and measurement we'd also have only got a fraction of the tyres tested.

I'm also going to shout myself out here, because this article is only based on half the data we collected. We have a corresponding road tyre optimisation piece coming shortly, which meant on the day I set up over 30 tyres tubeless, resulting in me having quite sore thumbs, and a fair amount of sealant all over me.

Finally, and most importantly, it must be said that thanks should go out to anyone who has subscribed to Cyclingnews in the recent weeks and months. Without you choosing to spend your hard-earned money on our premium content, we wouldn't be given the free hand we are to create it.

If you subscribe to Cyclingnews, you should sign up for our new subscriber-only newsletter. From exclusive interviews and tech galleries to race analysis and in-depth features, the Musette means you'll never miss out on member-exclusive content. Sign up now.