Samsung is one of the world’s leading manufacturers of semi-conductors – the microscopic bits of technology that exist on almost everything aspect of modern life but are so small we hardly know they are there. For a recent campaign, Micro Miracles, which won the much coveted Brand Impact Awards Best of Show: Campaign award, ManvsMachine showcased these incredible pieces of technology by using the same techniques Samsung use to make the semiconductors to create a short film. The result is a groundbreaking spot that tells the story of technological progress through a series of nanoscopic dioramas, capturing incredible detail at one-60th of the width of a human hair.

To find out more about the project, I caught up with Mike Sharpe, executive creative director of ManvsMachine, and Damon van Drimmelen, ManvsMachine’s design lead. For more in this series, where we go behind the scenes on creative projects, see our How we Made page.

How did you decide on the technological innovations you wanted to focus on?

Mike Sharpe: When we first read the script, we assumed that it was going to be done in CG. However, when we spoke with the agency (BMB) it turned out they wanted to do it for REAL and had already been researching whether it was possible. From that moment, we knew we wanted in and even at pitch stage BMB put us in touch with the technical partners that we needed in order to figure out the process – which was quite a crash course in nano-technology! As for the ’technological innovations’ showcased in the film, this was all part of BMB’s script – our job as directors was to work out how we could move from scene to scene in one flowing sequence.

Talk us through the process of creating these tiny models

Damon van Drimmelen: Once we had all agreed on the scenes, we went about creating the models in various ways. For the scenes with people, we cast actors and used photogrammetry to capture their poses and then worked them into 3D models along with any extra elements such as a rock, bean bag or car. Other models, such as the rocket, the solar farm and the satellite, were sourced and then adapted and all of them then had to go through the process of converting the geometry to be 3D printed at such a small scale.

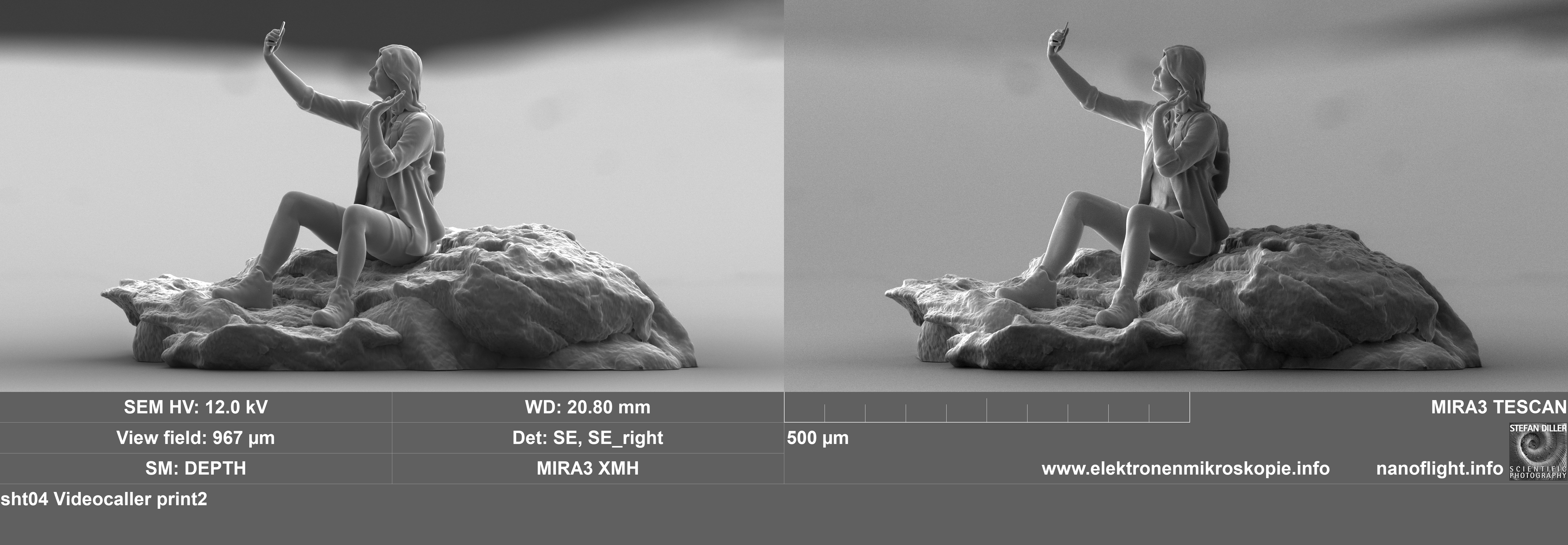

The models then went over to Nanoscribe in Germany, who use a cutting edge 2GL® 3D printing technique, based on Two-Photon Polymerisation, which fires two laser beams into a liquid – where the beams meet the liquid solidifies. This allows them to fabricate 3D models at a nano scope scale – sometimes smaller than the width of a human hair.

It’s a complicated, and expensive process, with a large margin for error. So, we printed four of each model as any micro-particle of dust, or tiny movement during the printing process would completely ruin the model and it’s only when you get the models under the microscope that you know if the printing was successful or not.

How did Stefan Diller help you bring your vision to life?

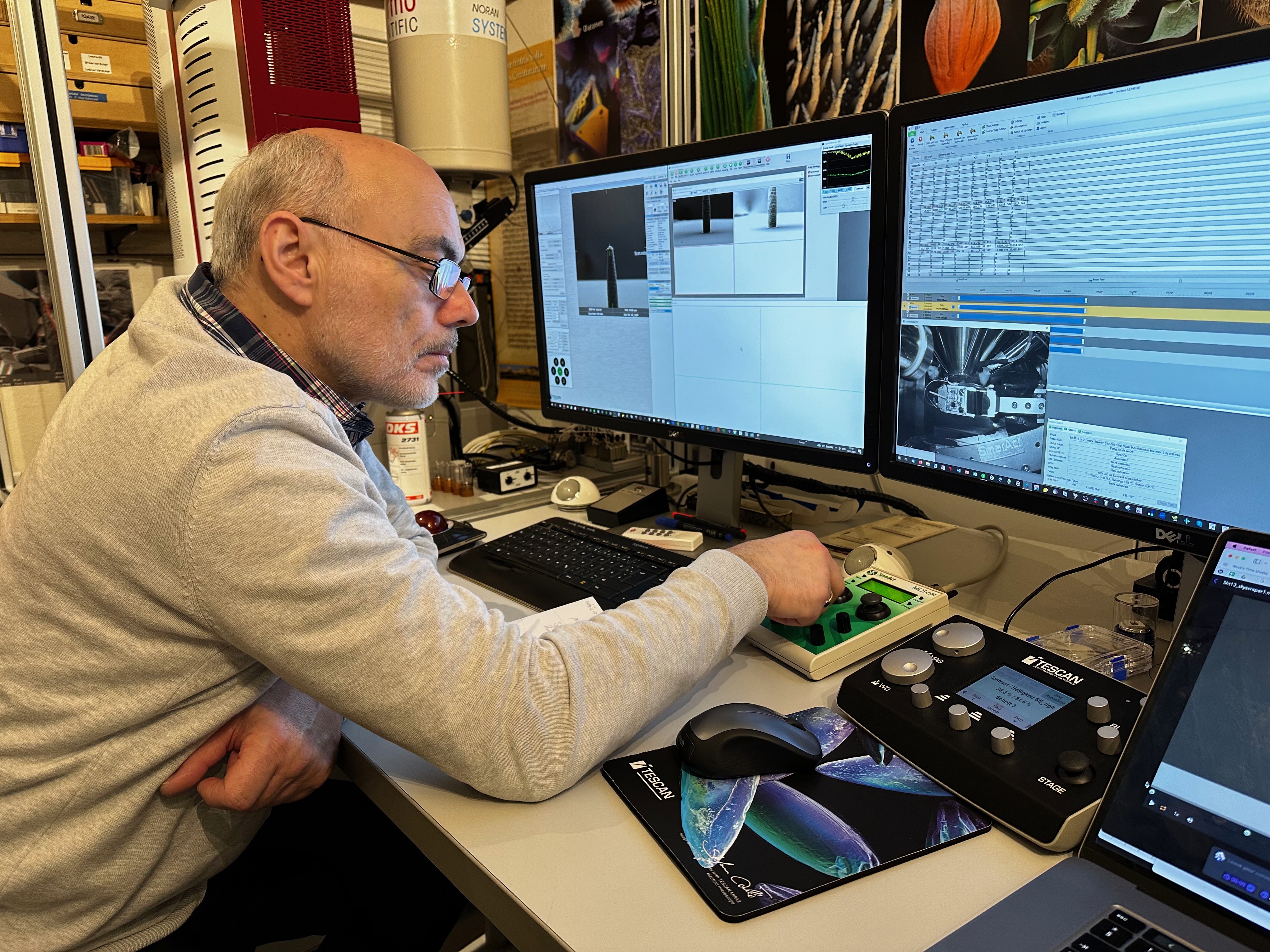

DvD: Stefan was vital. Traditionally, scaling electron microscopes (SEMs) only create still images, but his one-of-a-kind Nanolight® system allowed us to create camera moves around the models. It's a meticulous process, akin to stop motion, and he painstakingly recreated each shot from our animatic over a number of weeks.

What challenges did you come across in this project?

DvD: There were so many challenges operating at such a tiny scale and many obstacles to overcome. The fact that all the models had to be freestanding was a challenge both for printing perspective, as they had to be able to hold their own weight, but they also had to be scanned independently so we needed to be really clever in our storyboarding on how we moved from to another.

However, I think the biggest challenge was the scanning and subsequent editing of the film as this was such a long and protracted process. Stefan had to recreate each individual camera move, which each model, by eye. He would send us low-res previews of each shot and we would put them in our edit and feedback any notes.

The camera moves he created would only work once as there was no way of ever being able to put the models back in the same place again once they had been taken out of the SEM. Therefore, each sequence, with each model, had to be checked and approved in the edit before Stefan could move on. As I say, it was a long and laborious process and I can’t thank Stefan enough for his dedication and patience.

What did you learn from this project?

MS: So much! Obviously there was a lot of technical knowledge to learn, as previously stated, but the main learning for me was patience, collaboration and trust.

Which part of the process did you enjoy most?

MS: In the creative industry, we often say ‘it takes a village’ to make our work, but when you are doing something genuinely ground-breaking and new you really have to band together; to listen to all points of view, to trust the experts, to go on a journey of discovery without knowing the answers, to have the courage to adapt and change ideas and, most importantly, to leave the egos at the door and hunker down together – as a team. There really is no other way and it was HUGELY rewarding to work in such a collaborative way with so many amazing individuals across all aspects of the production.

What’s your favourite part of the finished work?

MS: We used the actual data from the SEM to show the scale in the UI graphics and it still blows my mind when I watch the film just how small the sculptures were. I’m beyond proud that we managed to do it for real and to have made a film in the nanosphere is utterly bonkers!

How do you think this identity helps Samsung stand out?

MS: Samsung is a company that needs to constantly innovate and be at the forefront of technology; films such as this that are truly ground-breaking support that company ethos in an engaging way. The fact that the creative approach is so neatly woven into the product itself is a genius move on the agency’s part and full credit to BMB for having such a brave idea in the first place!

What’s the feedback been like so far?

MS: Generally people can’t believe it was done for real and that’s testament to just how insane it all is! It was a real labour of love and took a long time to make so it’s really gratifying to see it getting so much love and picking up awards.

How does it feel to win the Best of Show (Campaign) at the BIAs?

MS: Such an honour. We knew we had won Gold but to win Best of Show too was an unexpected thrill and I couldn’t be prouder of everyone who worked on the film. Thanks BIA!

To explore more BIA winners see our Brand Impact Awards 2024 results page.