Since its beginnings in 1944, US furniture maker Emeco has been a champion of sustainable production. Its first-ever product, the Navy chair, was, and still is, made from 80 per cent recycled aluminium. Over the years, Emeco has expanded its material innovations to include reclaimed wood, recycled PET plastic, and polypropylene (not to mention initiatives such as ‘The next 150-year-old chair'), making its recent foray into upholstery a natural progression.

Emeco 'No Foam KNIT'

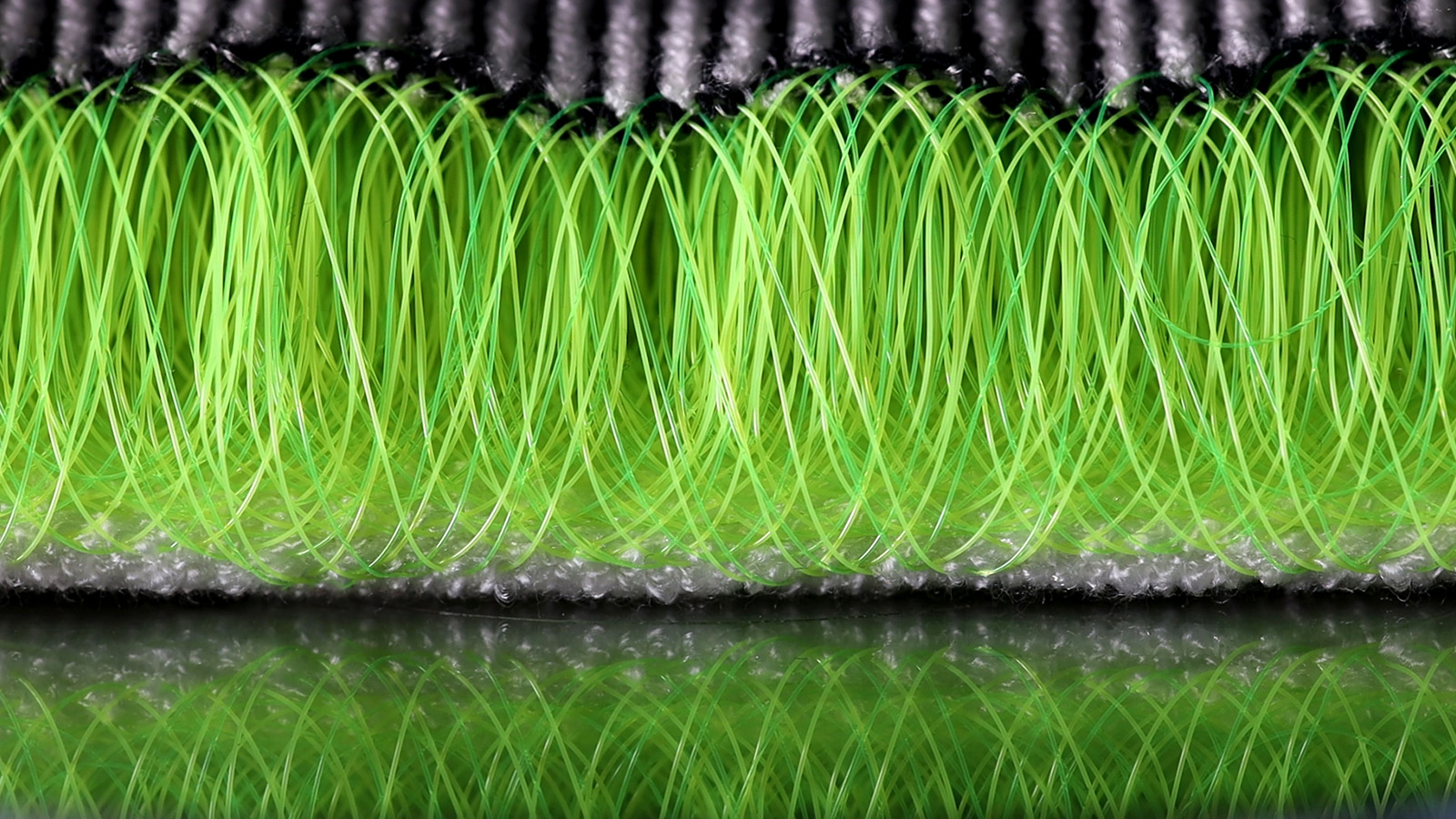

The present picture is bleak. Most upholstery relies on petrochemical-based foam, adhesives, and synthetic textiles that contribute to pollution, waste, and toxic emissions. Recycling is often impossible due to the mix of materials, with most ending up in landfills or incinerated. To address these issues, Emeco partnered with the Self-Assembly Lab at Massachusetts Institute of Technology (MIT) to create No Foam KNIT, a fully recyclable, mono-material upholstery textile.

The project, recently showcased at the brand’s Venice Beach headquarters, Emeco House, uses an innovative 3D-knitting technique where the yarn functions as both skin and foam replacement. This soft cushioning, springy structure eliminates assembly waste by removing traditional cut-and-sew processes, and because it is made entirely from a mono-material textile, it is fully recyclable at the end of its life.

Beyond reducing the environmental footprint of upholstery, the technique opens new and exciting possibilities for manufacturing and design in terms of functionality, customisation and aesthetics – Emeco says it’s exploring how this breakthrough could influence both current products and future developments.

‘Since the 3D-knitting technology enables so many different aesthetic expressions, we see potential for numerous uses and applications,’ says Jaye Buchbinder, the brand’s head of sustainability. ‘Emeco’s North Star has always been to make more with less, and that is exactly what No Foam KNIT does. We are excited about the possibilities of this textile innovation and how it can inspire positive change in the furniture industry and beyond.’