Intel has revised the construction schedule for its Ohio One semiconductor manufacturing site in New Albany, Licking County, delaying its launch to the next decade. The first phase (Mod 1) will now be completed in 2030, with production starting between 2030 and 2031. Mod 2 is set to finish in 2031, with operations launching in 2032. The company is slowing down the facility's construction to align its investments with market conditions. However, Intel stressed that it could accelerate construction if needed.

Intel originally planned to complete the first phase of its Ohio site — once called the Silicon Heartland — in 2025. However, massive investments amid uncertain demand made Intel push the completion of the first module to 2027 or 2028. Now, the company believes it will need its fabs in Ohio only in 2030 and beyond. The delay suggests that it does not expect demand for its production capacity to skyrocket soon, which may be a not-so-positive development. On the other hand, Intel will also not have to invest heavily in its Ohio site now, which is good news for the company's balance sheet as it is struggling to return to profitability. Investments in production equipment are the most significant investments in semiconductor fabrication facilities, so by delaying them, Intel significantly cuts its capital expenditures for the 2025 – 2028 period.

The upcoming campus will cover approximately 1,000 acres (4 square kilometers), accommodate up to eight semiconductor fabrication plants, and foster space for support operations and industry partners. Intel previously estimated that fully developing the site would require an investment of around $100 billion. The first round of investments was set at around $28 billion.

Given the new schedule for the Ohio One (or the Silicon Heartland?) fabs, expect the new facilities to use process technologies that the company will develop after its 14A and 14A-E, currently set for 2026 – 2027 introduction. These nodes will rely on ASML's Twinscan EXE:5200 or more advanced High-NA EUV tools that cost $350 million per unit.

"We are taking a prudent approach to ensure we complete the project in a financially responsible manner that sets up Ohio One for success well into the future," wrote Naga Chandrasekaran, executive vice president, chief global operations officer and general manager of Intel Foundry Manufacturing, in a message to employees. "We will continue construction at a slower pace, while maintaining the flexibility to accelerate work and the start of operations if customer demand warrants, but I want to be upfront and transparent with you all about our current plan."

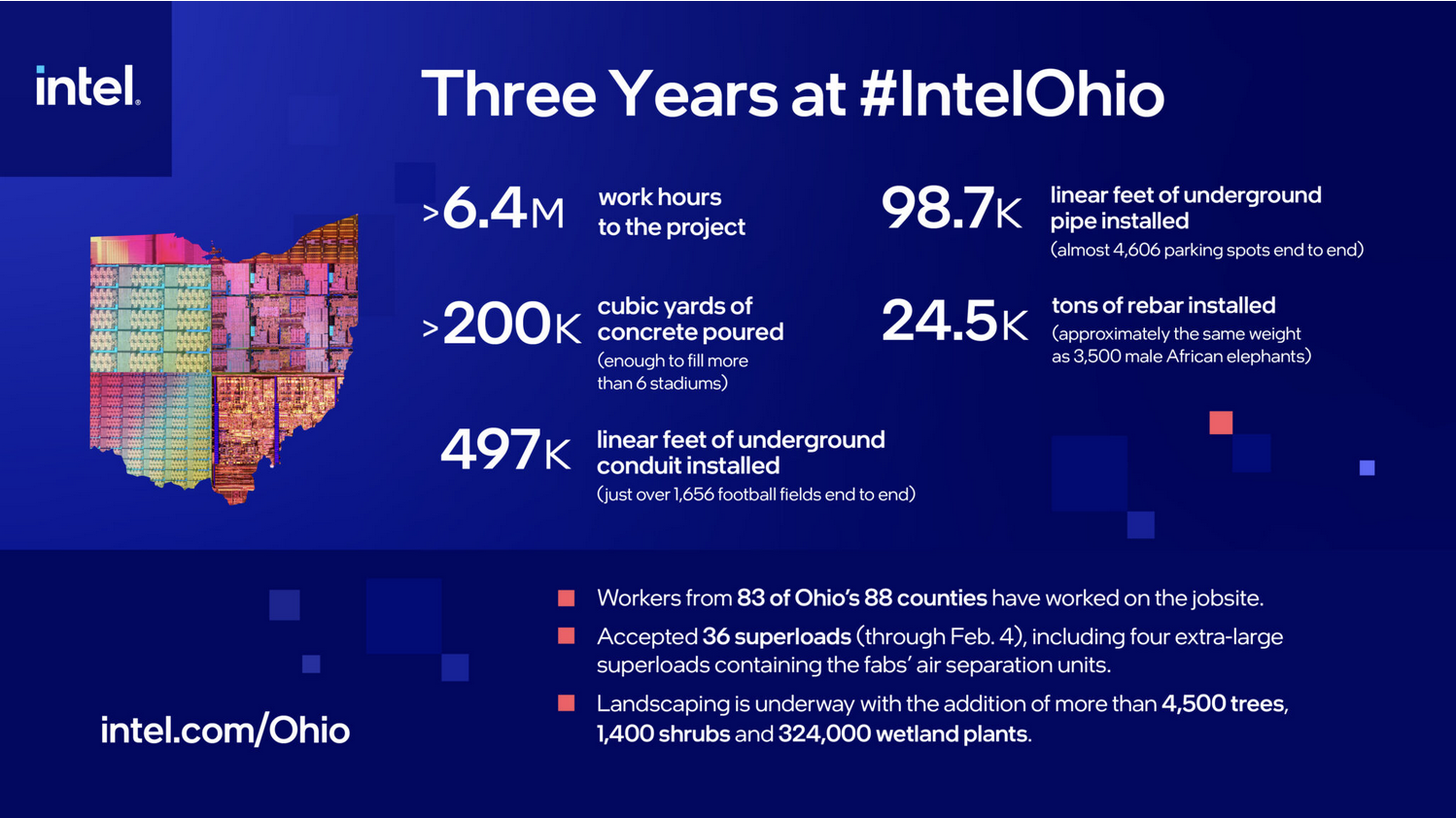

Intel began work at the site in 2022. Since then, construction at the site has advanced significantly. The project recently reached a milestone as the underground foundation was finished, and construction above ground has begun. According to Intel, since the beginning of the construction, the site has accepted 36 superloads (through February 4), including four extra-large superloads containing the fabs' air separation units. More than 6.4 million labor hours have been invested, covering key installations such as underground piping, 200,000+ cubic yards of concrete, and sub-utility trenches (SUTs). Office structures are also taking shape.

One interesting thing about the Ohio fab is that despite the revised timeline, hiring has already begun, with Ohio employees training in Arizona, New Mexico, and Oregon ahead of the local facility's launch. Presumably, Intel is training employees to install production tools and other machinery. Workforce initiatives are set to expand as operational dates approach.