You have been 3D printing for a while, and your machine starts producing some strange noises out of the blue. What steps do you need to take to fix it? Most of us will conclude that it has become old and must purchase another or look for a professional to fix it. That should not be the solution, as you can solve the issue alone.

3D printer noise is a common issue, and even if you have never encountered it you might experience it one day. It is most common in do-it-yourself FDM 3D printers and cheaper ones; however, even the best 3D printers might experience the same issue. Below, we break down the leading causes of 3D printer noises and how to solve them.

Main Causes of Noise in 3D Printers and How to Solve Them

Below are the main reasons why your 3D printer is noisy and the tips you can follow to rectify the issue.

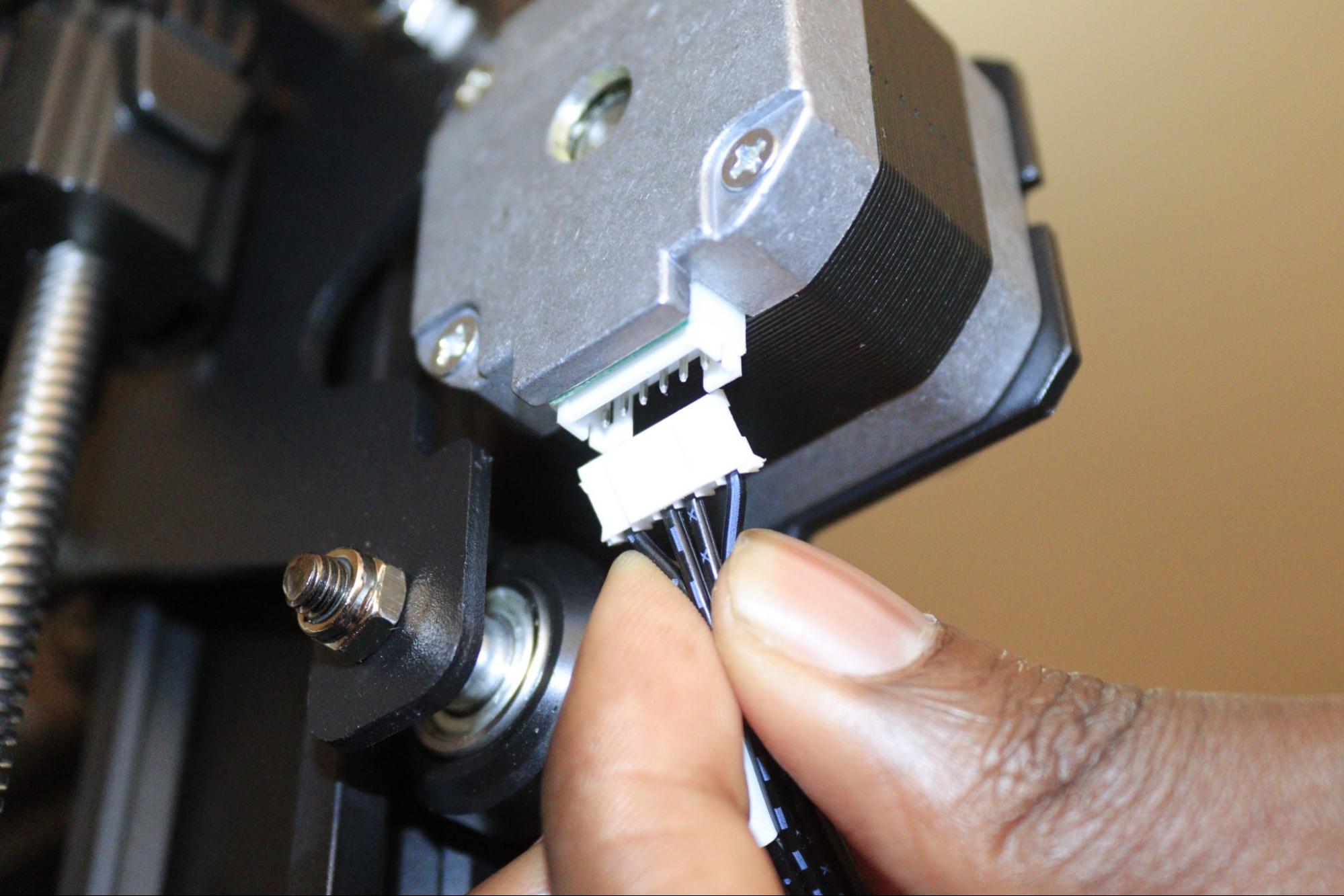

1. Stepper Motors Are Not Set Correctly

The stepper motors settings come in our first position as the leading cause of noise in the 3D printer as it’s responsible for moving the machine around. If the settings are off, the 3D printer can produce noise as it struggles to move the other parts. To address this issue, ensure the wires are connected appropriately and properly calibrate the motors.

In addition, you can also install motor dampers to reduce the noise. The dampers are made of rubber or plastic materials and work by absorbing the vibration of the motors hence reducing the noise.

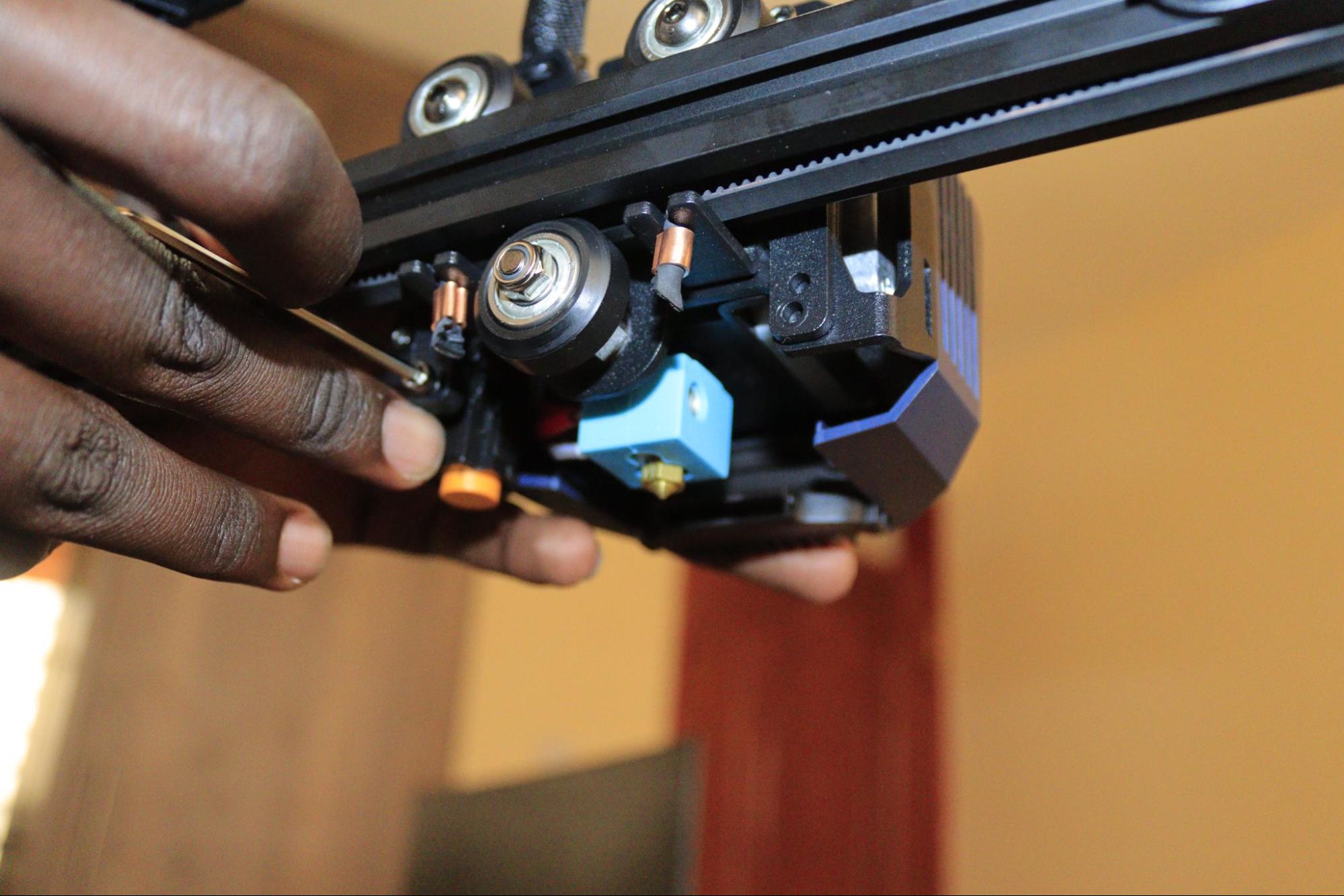

2. Extruder Issues

The extruder contains gears and a drive mechanism responsible for pushing the filament through the nozzle and moving the entire extruder from one end to the other. You might hear noises if any of these parts are not functioning correctly. You need to inspect the filament path to ensure there are no obstructions and also ensure proper alignment and tension of the extruder gears so that the extruder can move smoothly and the filament extrudes without any difficulty.

You should also check on the print head harness and ensure it is not too tight or loose, as this can also affect the movement of the extruder.

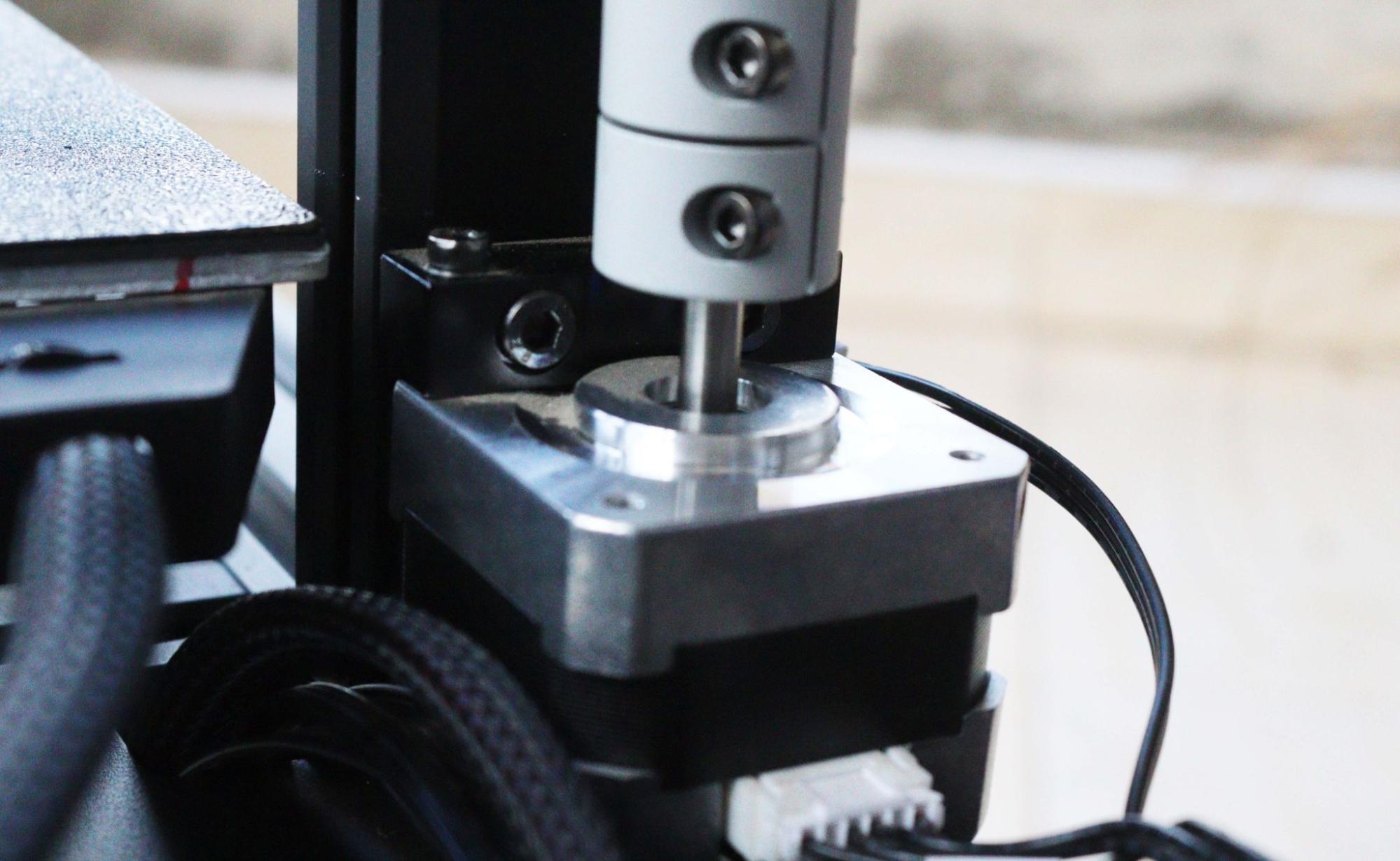

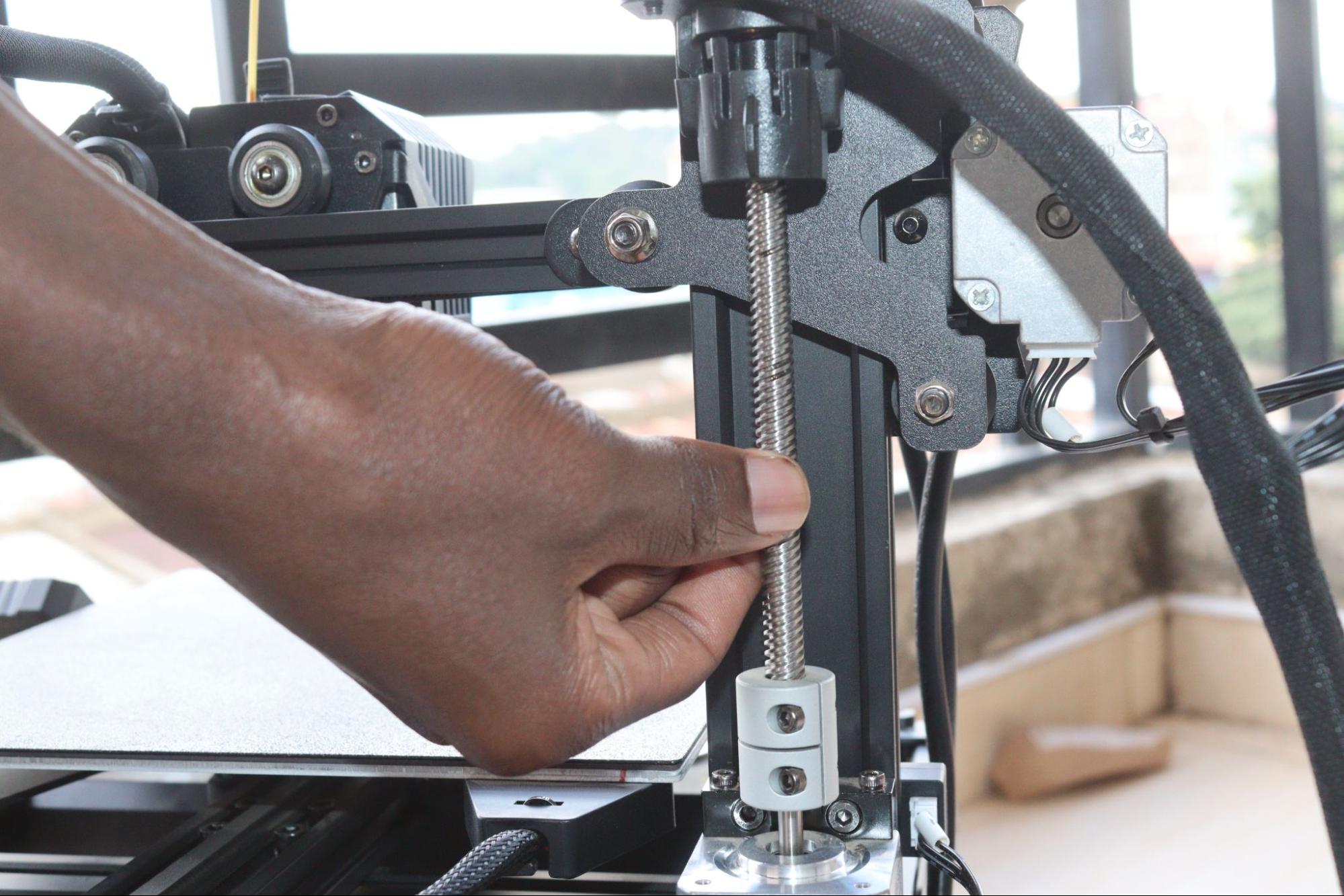

3. Z-Axis Wobble Not Properly Aligned

If the threaded rod is bent, it will cause noise as it moves, and you need to align it so that it moves smoothly. Also, if the coupling of the Z-axis is loose because of continued usage or wear and tear, you must replace them and ensure they are securely fastened.

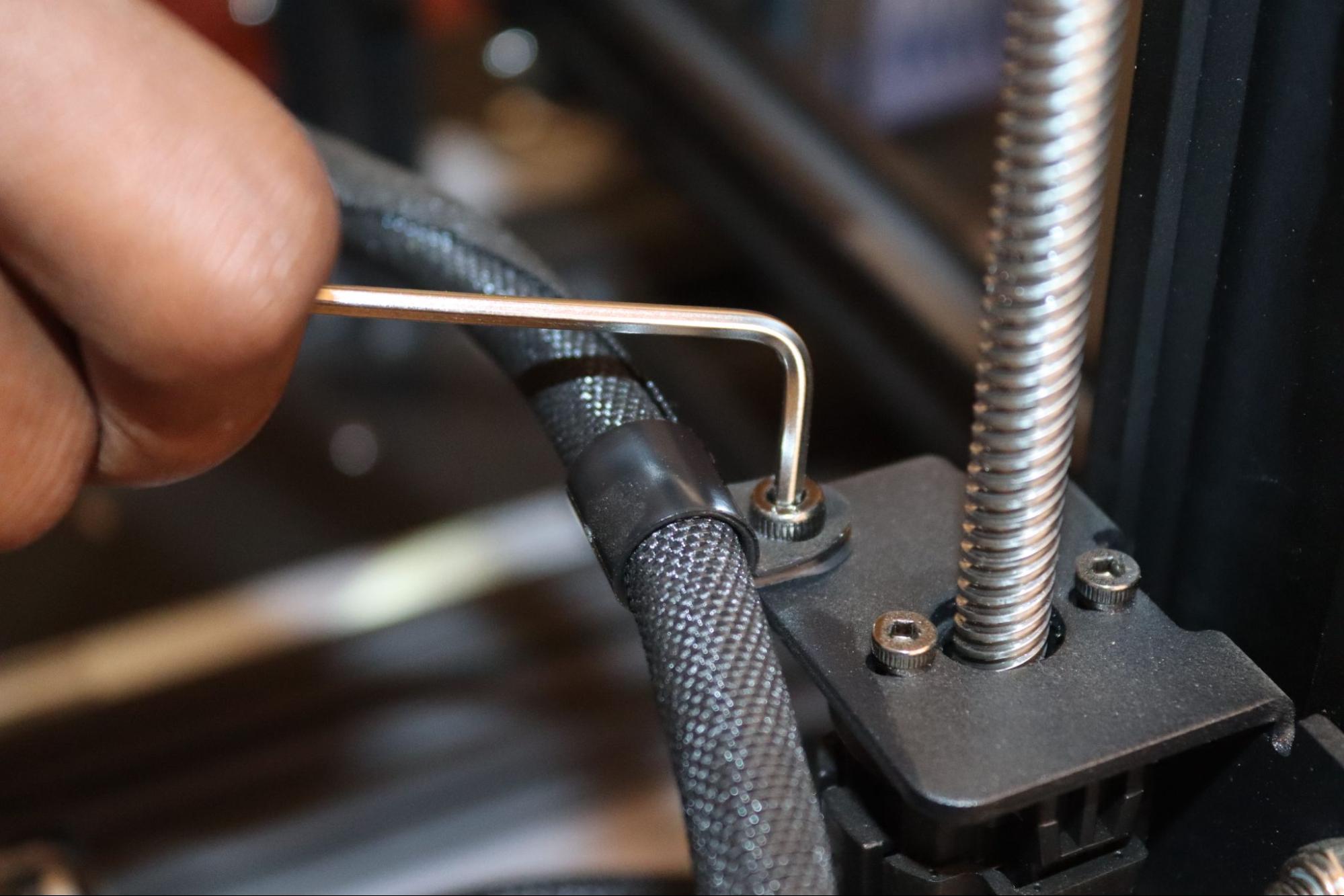

4. Loose Screws and Nuts

Vibrations during printing can cause screws, and nuts to loosen over time, resulting in rattling noises. You need to check your 3D printer and ensure it is well-tightened regularly. As you do so, don’t over-tighten, as it can cause other issues.

5. 3D Printing At a Very High Speed

At high speeds, the 3D printer can generate a lot of vibrations as the stepper motors move and change direction quickly, resulting in noise. This is more prevalent when the motor drivers are not calibrated well. Also, as the extruder moves quickly from one place to another, it can also cause vibrations.

Though printing at high speed is beneficial for reducing printing time, it can also increase vibrations and even compromise the quality of your print. So you need to use the optimum speed for your machine. You can easily adjust the printing speed on your slicer before you start the process.

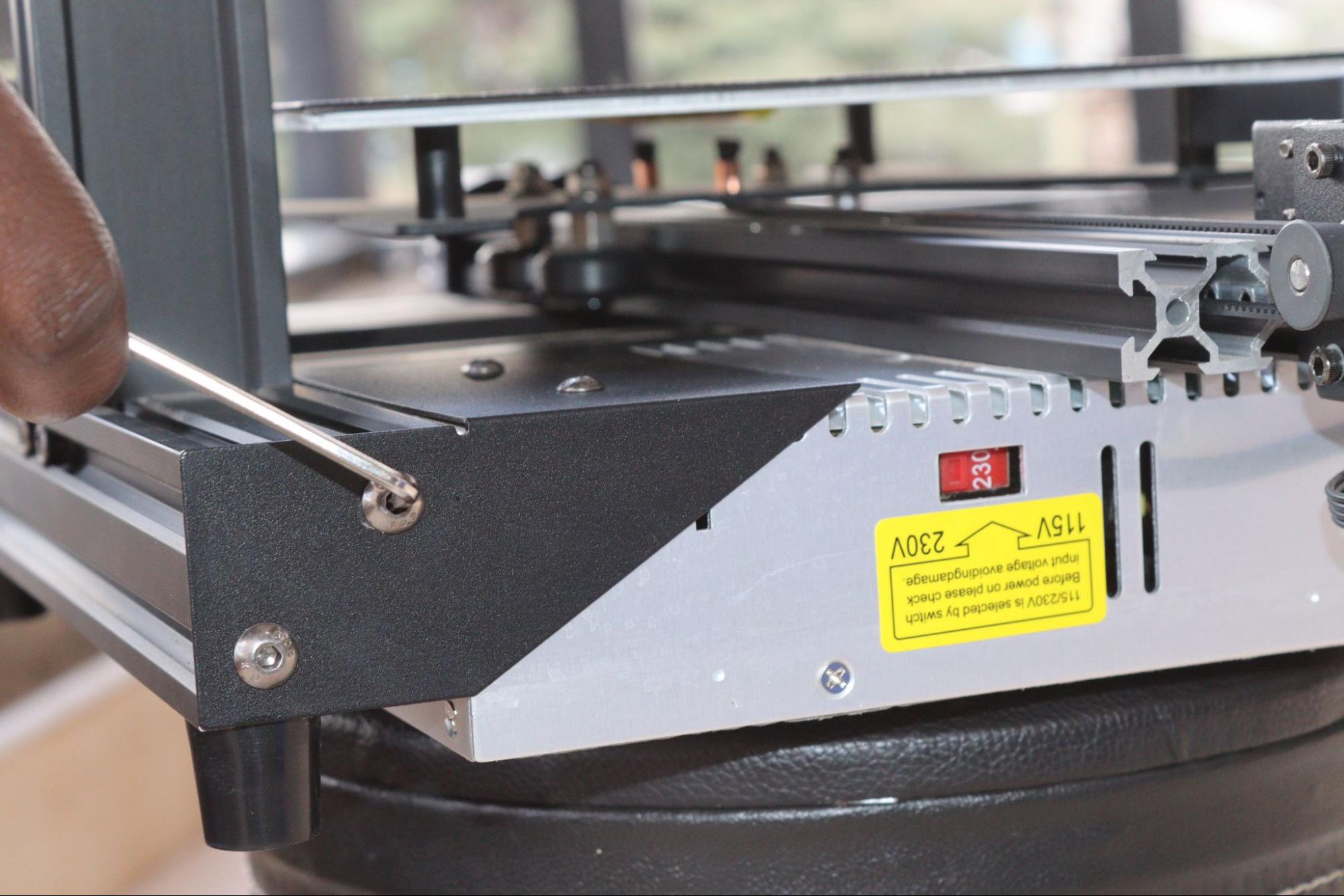

6. Placing the 3D Printer in an Unbalanced Place

If you place your printer on an unstable table or surface, the vibrations in the machine will spread to the surroundings and increase the noise. So you need to ensure that the table on which you place your 3D printer is stable and sturdy so that even if there are vibrations, they are not transmitted.

You should also consider the type of material you use for the table or surface you place your 3D printer. Some, like glass, can amplify the noise levels even further.

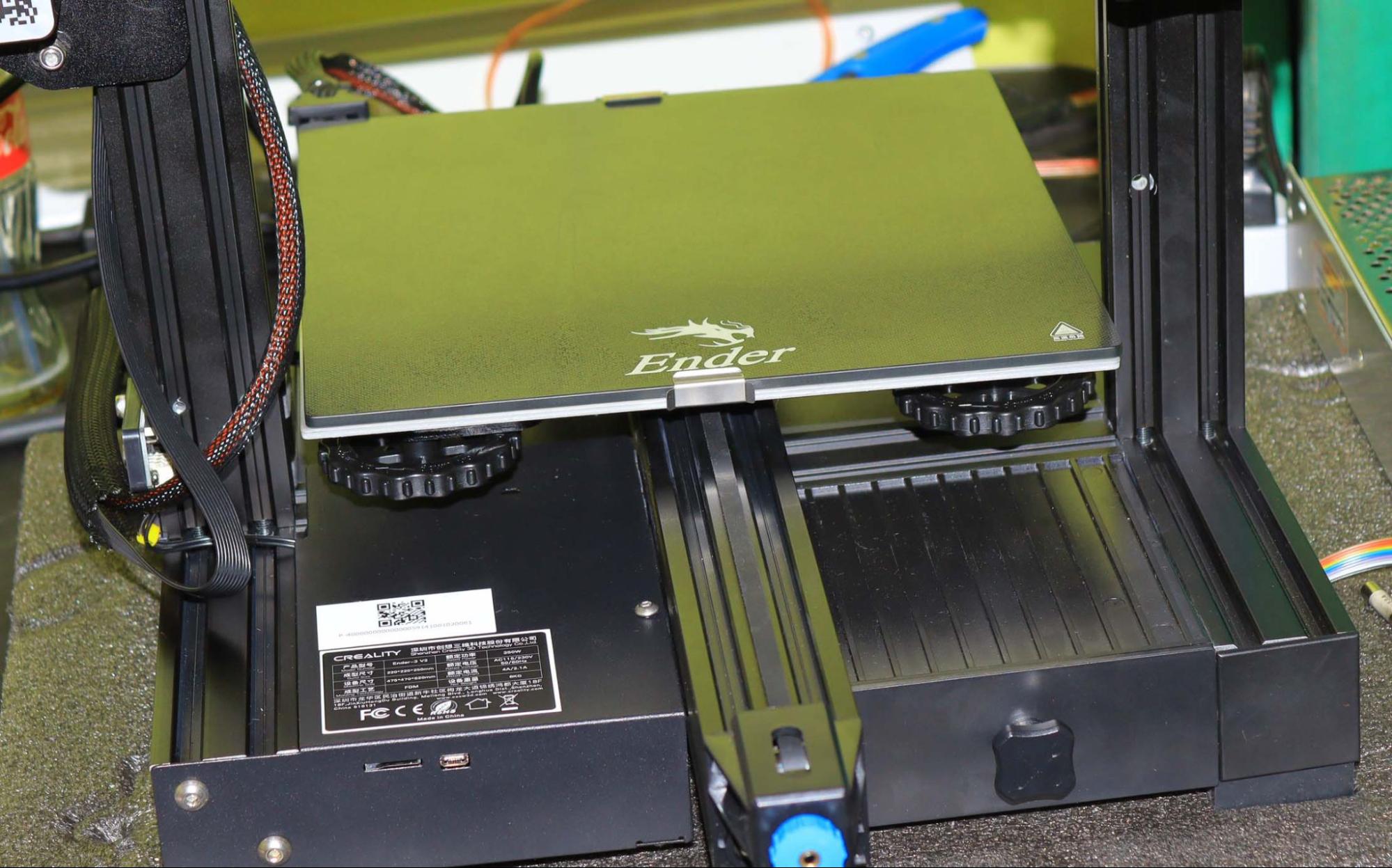

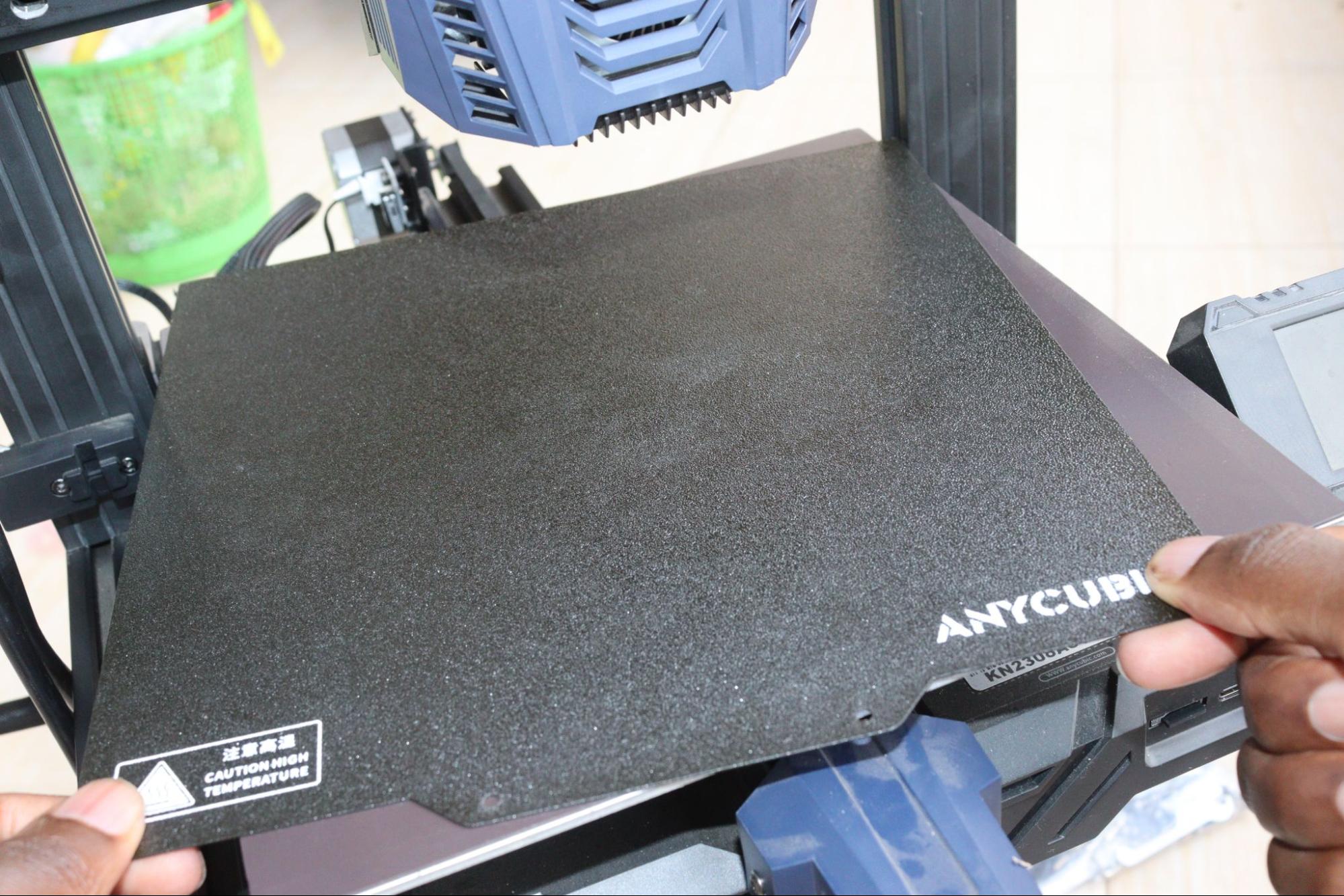

7. Misaligned Build Plate

If the build plate is not balanced or aligned correctly, it will shake when the bed shifts from one side to the other, particularly when it comes into contact with the frame. Moreover, it can cause straining of other components leading to increased friction and noise. In addition to balancing the build plate, you should ensure that you level the print bed appropriately.

8. Fan Noise

If dust, debris, or filament particles accumulate on the fan blades, it can disrupt the smooth airflow and cause the fan to work harder, increasing the noise it produces. So, if you hear abnormal noise from the fan, you should clean and remove any accumulated debris or dust. If the problem persists, you should consider removing and replacing it.

9. Twisted Filament

If the filament, even if it's one of the best filaments, is twisted, it can create resistance as the extruder pulls it. This can cause the extruder motor to work harder and produce noise. The twisted filament may also rub against the other parts of the machine, generating additional noise. You can untwist it and ensure that it extrudes smoothly. This is a minor issue, but the sound it produces when pulled can be irritating.

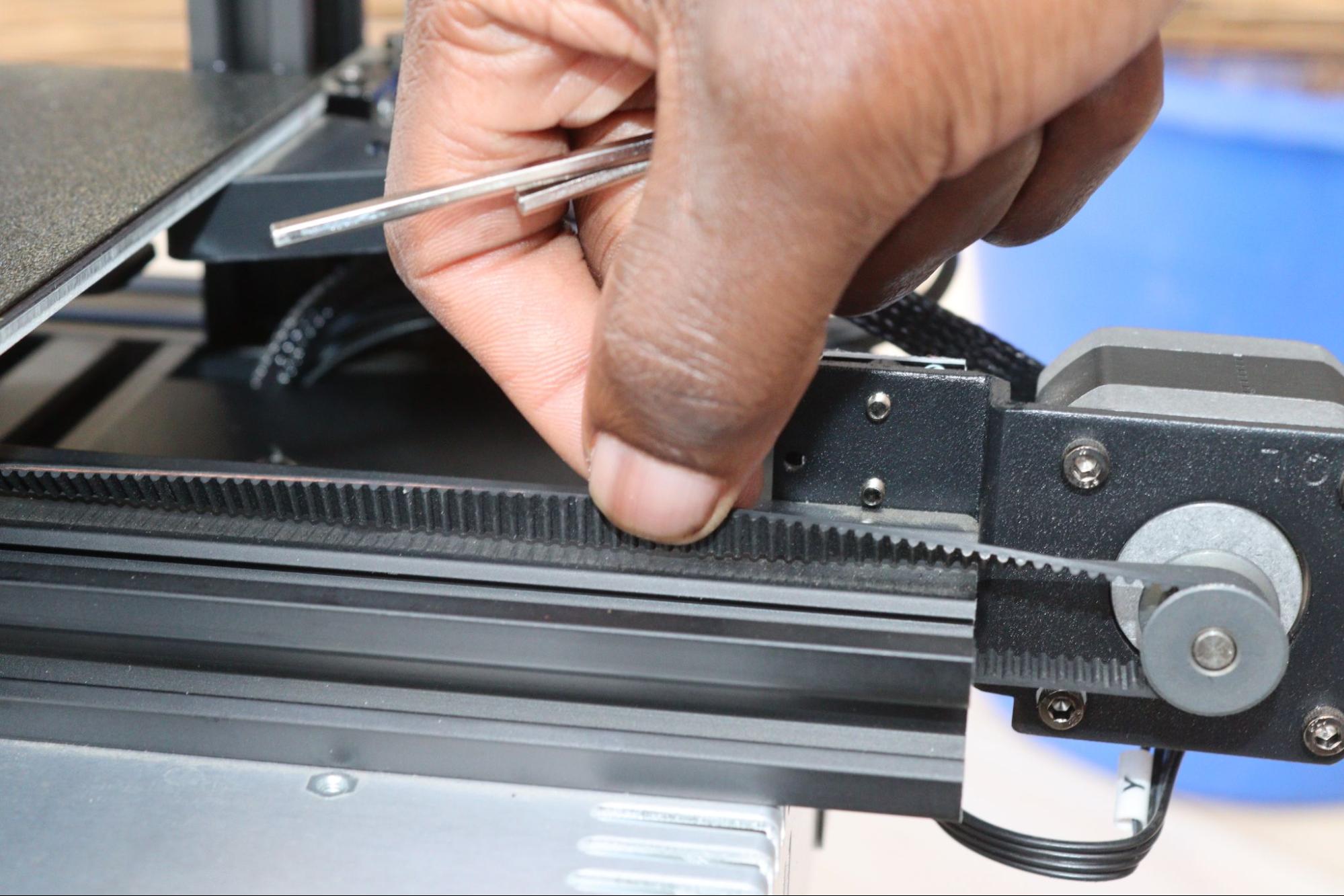

10. Too Tight or Loose Belts

Belts that are either too loose or too tight can result in noise during operation. If the belts are too loose, they may slip or skip over the pulleys, producing clicking or grinding sounds.

Conversely, if they are too tight, they can cause excessive friction and strain, and your machine can start producing strange sounds. You must adjust them and ensure they are not too tight or loose. Moreover, you should also inspect the belts for signs of wear or damage and replace them if necessary.

If your 3D printer is making more noise than usual, it's important to investigate the source of the issue. To do this, you can use these ten steps we have highlighted to troubleshoot the problem. In many cases, it can be as simple as tightening a few screws or replacing a part. If the noise persists, you may need to put a soundproof enclosure around your 3D printer to keep the noise under control or purchase another machine for your peace of mind.

MORE: Best 3D Printers

MORE: Best Budget 3D Printers

MORE: Best Resin 3D Printers