Often it’s said that the shaft is the engine of the golf club. Simply put, it’s a crucial piece of equipment – the timing device for the swing. No one understands this better than Fujikura, the most trusted wood shaft brand on the PGA Tour.

Since its inception in 1994, the company has been at the forefront of design and development to produce the world’s best golf shafts, helping golfers of all levels get the best performance from their clubs.

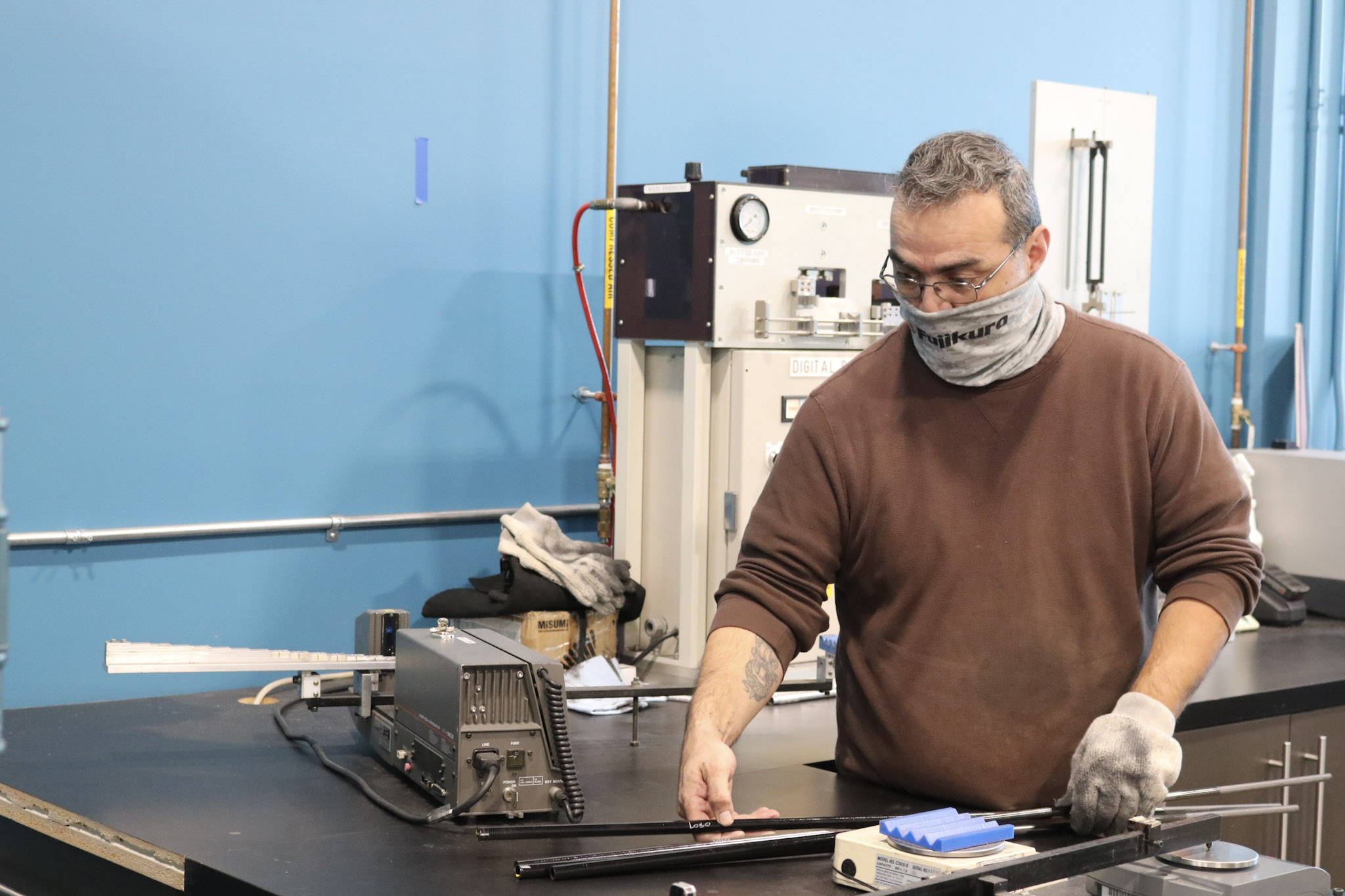

Every Fujikura golf shaft is precisely designed through the use of its Enso 3-D motion capturing system – the first club fitting system that measures information both before and after the ball is hit. As a result, the club and shaft are dynamically measured and recorded throughout the entire swing.

Marshall Thompson, fitting and tour representative, has been with Fujikura for 15 years, during which time he has witnessed many a scientific breakthrough. If we’re nearing the ceiling in clubhead design, the same cannot be said of shafts. We caught up with Thompson to find out more about how Fujikura is setting new standards in shaft design and performance.

Tell us about your role working for Fujikura...

I started out as an intern in the tour department. I remember my interview phase and being asked whether I knew how to fit. I said no, and they asked me whether I knew how to build clubs. I said no. They looked at me and said, “Good, we’re going to teach you the right way!”

I’ve worn a lot of hats at Fuji, from product design and running the fitting studio to being a Tour representative travelling across the globe fitting the world’s best players. We’re a passionate group and I’ve been lucky enough to have the right mentors, such as CEO Dave Schnider, and Pat McCoy and Jon Hovis, who were the tour representatives at the time.

How has the company evolved during your time?

In the late ’90s we had an opportunity to bring after-market shafts, using some very exotic materials, to the consumer market. I remember when we launched our Speeder 757. We went to our charter dealers network and said, “Hey, we’ve got this Triax material, a three- directional weave, it’s very stable, it’s going to lower launch and lower spin.” They almost laughed at us because there was nothing on the market that was that cost at the time.

We took it to the PGA Tour and within the first year we dominated. That’s when our chartered dealers called us back and said, “Hey, you know what, we’ll take that shaft.” That was the evolution of the Speeder 757, 661. Fast-forward a little bit and we had Rombax, which was very popular, then the Atmos Tour spec line, Pro Tour spec, and now we’re on to Ventus.

What have been the key moments in shaft design?

It’s about getting better materials, and also you get better at designing the product. We’ve pushed ourselves in that regard to create different profiles that change bending stiffness and also torsional stiffness.

When we got our Enso 3-D motion-capture camera system in about 2009, that was kind of an aha moment. We were able to see how a shaft was bending, deflecting and twisting in 3D space. We could really see how shafts could manipulate ball flight and how we could make not only tour players better, but also amateur golfers.

What would you say makes a Fujikura shaft unique?

Well, firstly, I would say the amount of R&D that goes into it. We’re very critical of the testing data that comes through. Data runs the world. We have launch monitors that give us down range data, which is very important to what we do in terms of shaft design.

Then, having this Enso 3-D motion-capture camera system allows us to take different swing speeds, different swing types, different shaft profiles and different materials and analyse how we lay those up. We can see what impact it has for every single swing type and every single golfer on the planet.

We’ve always prided ourselves on being a fitting company, and we make a lot of different profiles that fit a lot of different swing types and swing speeds. That’s one of the reasons why we stand out and why we’ve always done extremely well.

What makes the new Axiom iron shaft such an exciting product?

There is quite a bit of excitement and anticipation about Fujikura Axiom for sure, including from us. We’ve not had this type of buzz around an iron shaft in a very long time, or maybe ever. This is because it features the same full-length VeloCore technology as Ventus but also because they are designed differently to anything we’ve done in the past in our Pro and Vista Pro lines. I’m confident Axiom will really resonate with golfers of all playing levels.

What’s the difference now?

Now, with these new parts, we’re making three different profiles – so you’ve got the longs, the mids and the shorts. What that means is we only have a two-and-a-half inch parallel tip section, which gives a lot more room for design, and also it’s going to keep the weight constant.

Being that constant weight, having a two-and-a-half inch parallel tip section and using VeloCore technology – which was a staple in the Ventus line-up – that’s why it has taken the tour by storm. To dive into the weeds a little bit, it’s how we lay that material up.

You have got material that goes at a zero degree angle that affects your bending stiffness, and then you have material that goes at plus or minus 45 degrees and that affects your twisting stiffness.

Ventus was very good at stabilising the clubhead and not twisting so much, and also promoting a centre-of-face impact location. That’s what you’re going to get now within an iron. I think the consumer is going to see more consistency, more launch, more spin and higher peak heights.

To me, that’s crucial for all players of the game, primarily because you want the ball to come in at a steeper descending angle so it lands softer on the green. I think the consumers are going to love it.

What sort of feedback have you gained from the likes of Rory McIlroy around the Ventus shafts?

There’s a premium on tour and in the consumer market on speed and ball speed. With this focus on hitting it as far as you can, we’ve got a lot of opportunities with a lot of elite players over the last few years, and I think we won most of those battles because of the VeloCore technology.

Once you show a player more speed, it’s hard to turn away from that and that’s what Rory McIlroy gained. He was above 190mph ball speed, which he hadn’t seen before. What you’re also getting is consistency, which comes with the stabilisation of the product and hitting the centre of the face, therefore giving you more ball speed. So what impressed was the overall consistency and also the speed increases for a lot of these players.

When you’re fitting golfers with driver shafts, what are you looking at?

I’ve never taken the stance of pigeonholing somebody into a shaft just based on their swing speed. When I go into the fitting process, I’m always trying to find out what the player wants to do and what type of shot they currently play. Course conditions come into it as well: are the fairways soft? Are they firm and fast? That can potentially change the landing angles.

Everybody feels everything differently, too: how they load the product, how they bend and deflect that product. Sometimes it’s about going outside the box and not saying, “Well, you swing it this fast, you should be a senior flex,” because maybe they need to lower their launch and lower their spin, and they load it extremely hard so they would actually benefit from a lower- launching, stiffer-handle, stiffer-tip product. It’s getting with the fitter, discussing your goals and what you want to achieve and finding ways to go about doing that.

How do you go about balancing distance versus accuracy?

Everybody always says, “I’ll give up a little bit of distance to hit it straighter,” right? But when you give somebody ten to 15 yards, it’s hard to look away because in their head they’re already thinking maybe I’ve got an 8-iron in instead of a 6-iron, so the proximity to the hole will be a little bit closer.

To me, accuracy is the most important, but there are ways to be accurate and there are ways to be more efficient. It’s about getting the right length, and getting the shaft that squares up the most consistently for you and gives you the most consistent club speed, the most consistent ball speed.

Essentially, whatever helps you find the centre of the face most efficiently and is the most repeatable. That’s the goal. And with that you’ll get accuracy and distance.

What are the most common mistakes you see amateurs make when they come for a driver/shaft fitting?

Most golfers do a little research online before they come in; then they kind of control the fitting a little bit! Some golfers have a feeling already of what they think they need. There’s a reason why this person is a club fitter – they have been doing it for a long time. They see a lot of numbers, so let them guide you to be where you need to be.

All we need you to do is hit golf balls and then give us some feedback in terms of feel. Then just trust that this fitter knows the product inside and out. They know what heads potentially do to CG and MOI – it might go a little bit more right, or a little bit more left; it might spin a little lower or launch a little bit higher. Trust the expert.