In a move that turns thinking around wheel depth conventions on its head, Roval has updated its Rapide Sprint wheelsets to focus on the bike's leading edge.

The new models from Specialized's wheel brand feature a deeper rim depth at the front and a shallower one at the rear, defying conventional wisdom that has for years seen the industry do exactly the opposite.

The Sprint CLX wheels now pair a 63mm wheel up front, with a 58mm out back, while the lightweight CLX III model has a 51mm deep rim combined with a 48mm depth at the rear. The more affordable CL III is a “direct descendent” of the CLX and uses the same rim sizes.

The project was lead up by Lionello Bardina, Specialized and Roval R&D aerodynamics engineer with the deadline of this year's Tour de France. Ready to challenge the status quo, Bardina took what he’d learned from redesigned Specialized’s WorldTour race bike, the Tarmac, most notably that by optimising leading edges you can significantly reduce drag. Roval says the principle was applied to wheels resulting in thousands of shape iterations before Bardina and his team hit on the right combination for both the Sprint CLX and the CLX III.

Perhaps the greatest benefit of Bardina’s “aerodynamic coup” for the Rapdie CLX III wheels was the significant drop in weight compared to the existing CLX II model. By dropping a claimed 215g for a set weight of 1,305g, Roval says it's been able to maintain the aerodynamic properties and stable handling of its predecessor but now deliver faster acceleration thanks to it being so much lighter.

Roval say the feedback from its WorldTour teams "helped inform" the layups, with "each carbon ply type, placement and orientation" designed to improve stiffness, impact resistance and the overall strength of the wheel. Combined it makes the CLX III the all-rounder in the Rapide range.

But it’s not just the differing rim depths that define the new Rapide wheels. It’s also the rim itself. The new design features what Roval calls “uniquely wide bead hooks”. These FlatStop Bead Hooks are said to deliver “best-in-class pinch flat resistance”, with the Rapide CLX III requiring a claimed 39% more force to pinch flat. Roval is so confident in its testing standards and impact targets that it suggested to ASTM, the standards organisation, that its methods become the industry standard.

Said testing took place at Specialized’s HQ in California. Here Bardina and Senior Design Engineer Phillip Somers used the facility's wind tunnel to test various depth combinations as well as focusing how well the wheels performed with different tyres. The pair even used a CT scanner to enable them to get the best mating of rim and tyre.

‘CT’ stands for ‘computed tomography’ and the technology allowed them to scan the mating of different wheel and tire width combinations to show those that offered the best aerodynamic advantages. These were then fed into CFD programming. After thousands of variations Bardina and Somers determined that the best shapes all had one common factor, that the rim width was one millimeter wider than the tyre width, with a 21mm internal rim paired with a 28mm tyre the clear winner.

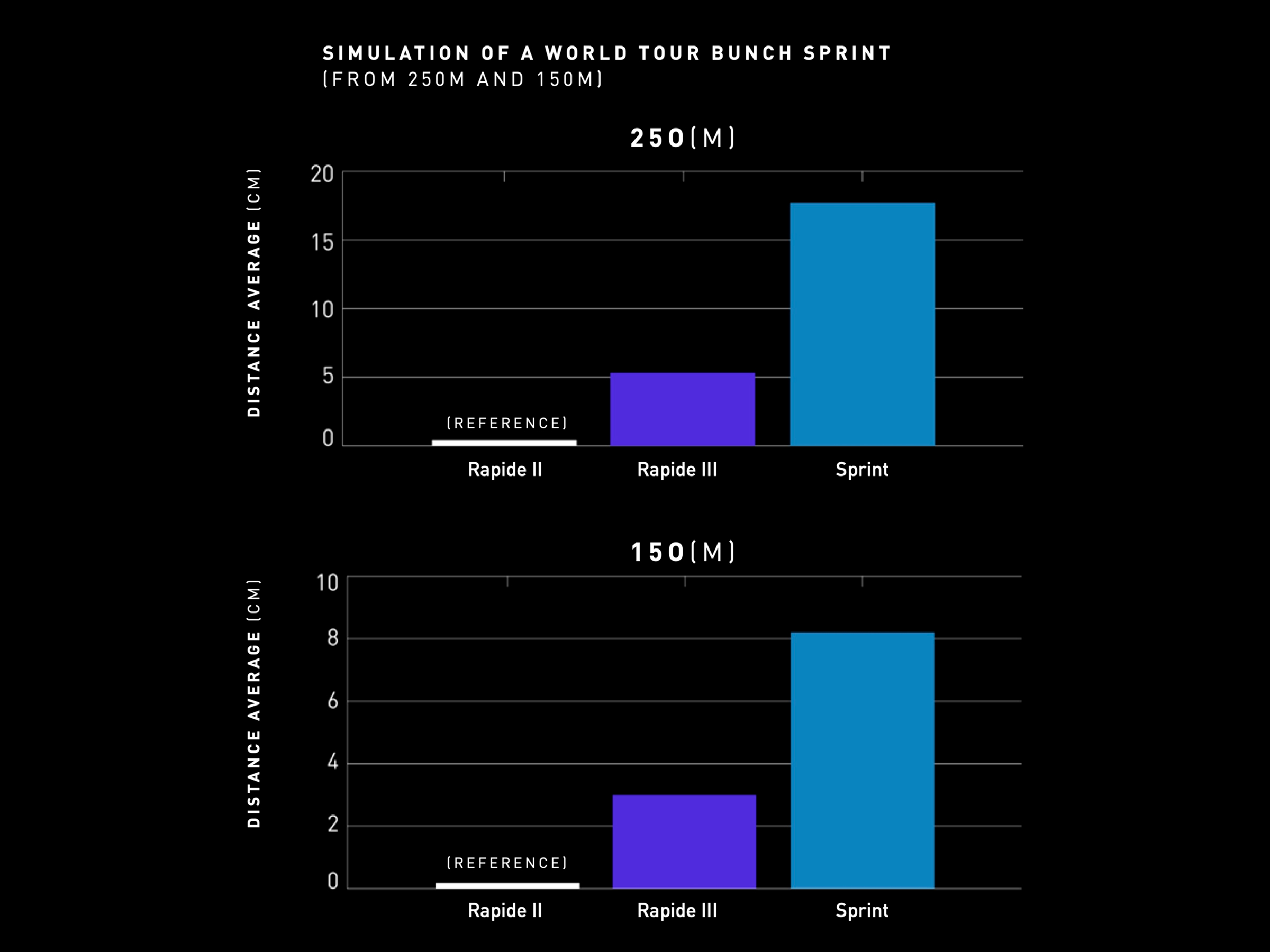

Roval calls the Sprint CLX the “fastest spoked wheels ever made”. To create some hard numbers to support this claim, Marcel Keyser, Roval Staff Engineer in Vehicle Dynamics ran a series of projections using MATLAB technology. He simulated sprints over 150 and 250 metres, starting at 55kph and ran through the three distinct phases: acceleration, when power is typically applied from behind another rider; maximum velocity, when the rider is out in the open and relies more on the aerodynamics of the wheel; and the final phase, when power is beginning to wane and again rely on aerodynamics to keep their power high as they hit the finish line.

The results show that compared to the Rapide II, the Sprint CLX is some 18cm faster over 250 metres and 8cm over 150 metres. When sprints are decided by millimetres, these numbers can make a difference.

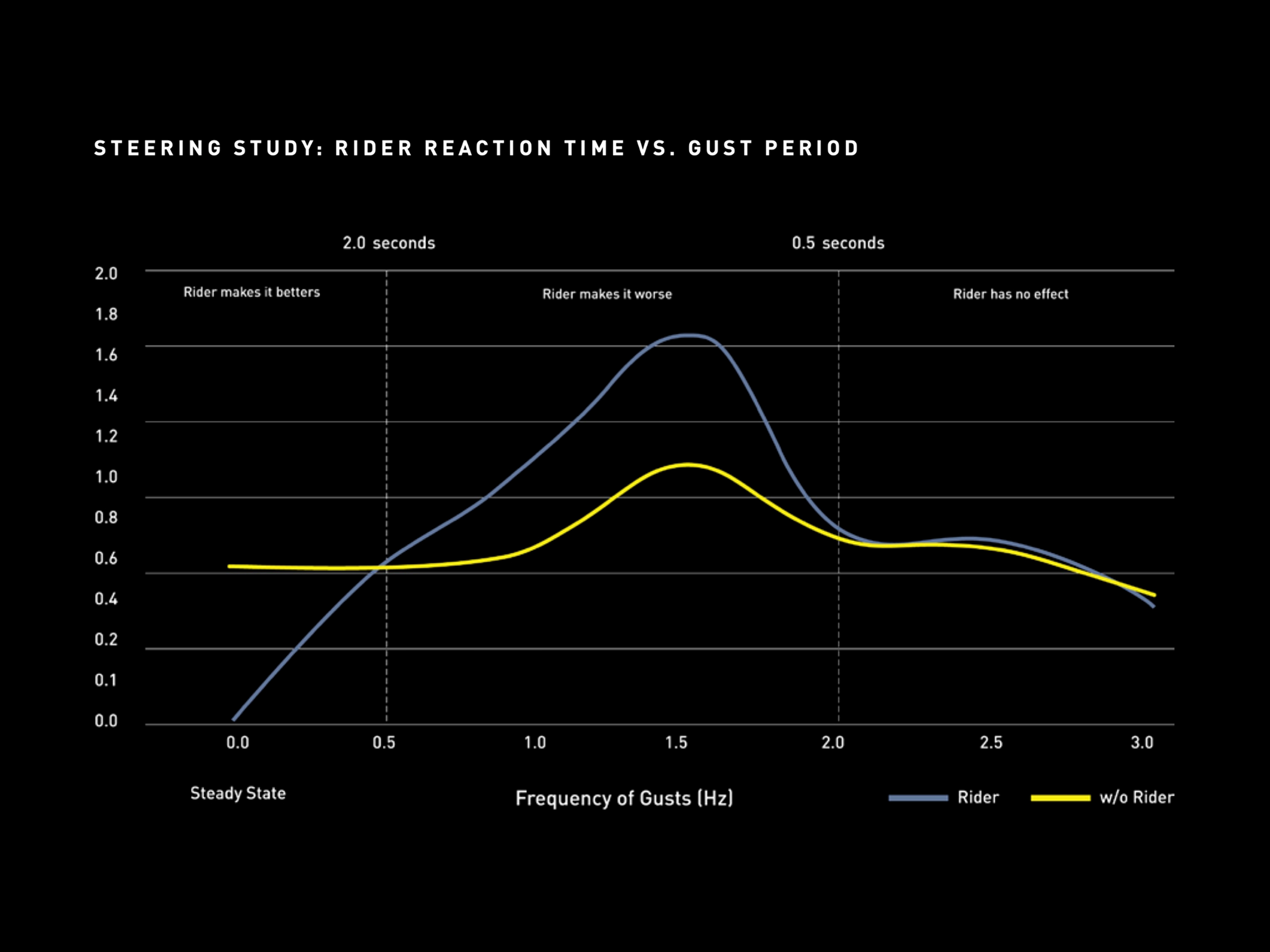

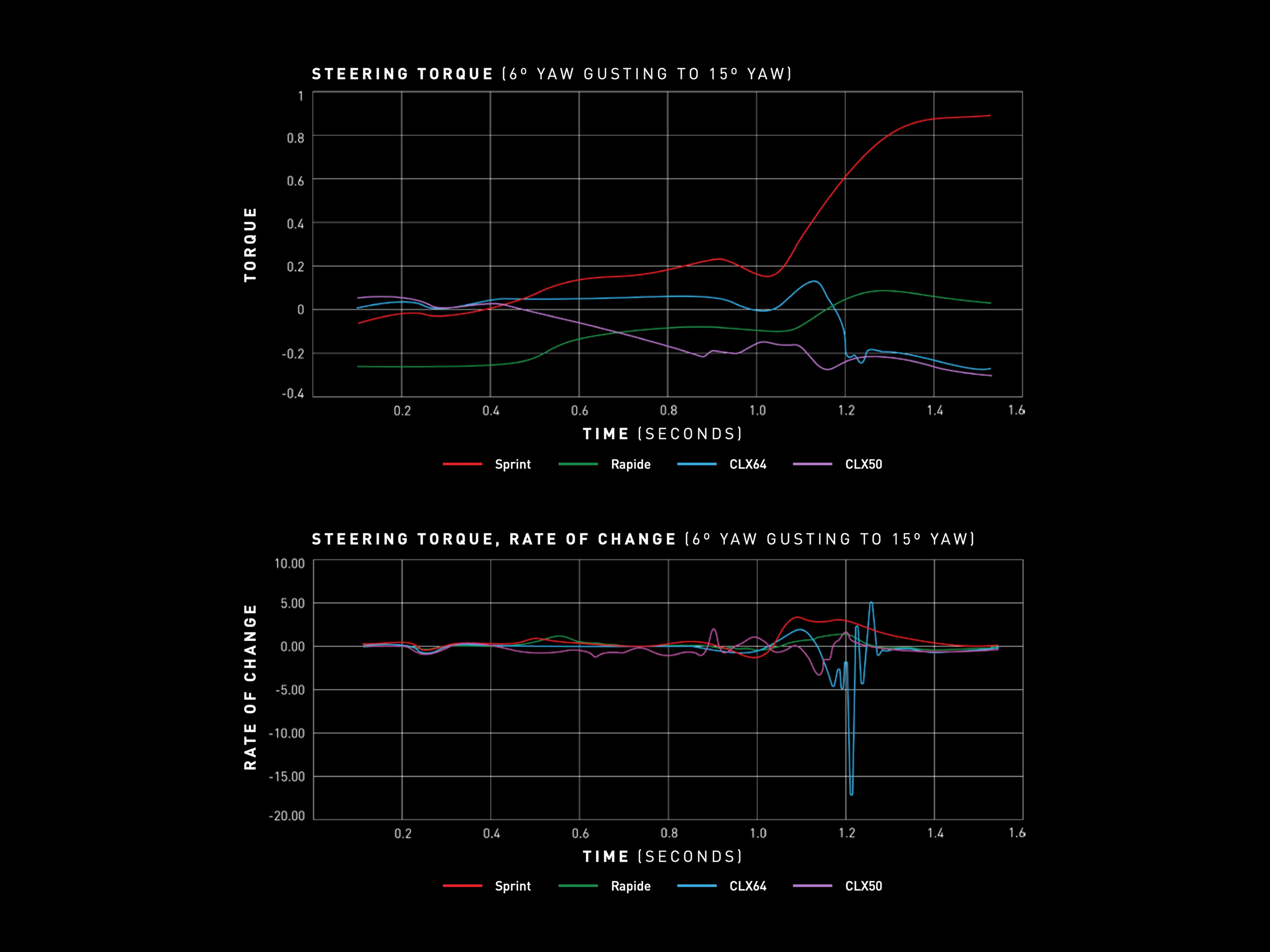

One of the main reasons for keeping wheel rims shallower at the front is manoeuvrability and crosswinds. The deeper the rim, the greater the risk posed by gusts of wind hitting the front wheel from the side. So Roval has sought to optimise the stability in wind gusts that last between 0.5 and two seconds, said to be the window that allows riders to react to the wind. The strength of the winds used in their testing conditions has not been revealed, and this is not something that can be recreated in a windtunnel.

With both wheels designed for different tasks, the Sprint wheels are created to deal with stronger input from the wind. Both models use Continuous Composite Spokes. Designed in conjunction with Arris Composites, each spoke weighs less than 2g, helping to save almost 100g across the wheelset. Roval says the spokes, which feature titanium fittings, are 20% stronger than traditional steel spokes.

We’ve yet to mention the Rapide CL III in more detail. This is because it shares much in common with the CLX III. That means the same rim depths front and rear, which results in a 35g weight saving, as well as the same FlatStop Bead Hooks. What differs is the rest of the build and ultimately the weight.

The aforementioned Roval x Arris spokes are replaced with DT Swiss Competition Race Straight Pull spokes. While the CLX III and Sprint CLX use Roval’s new lighter Low Flange Road hubs, with DT Sinc ceramic bearings and a DT Swiss 36T ratchet, the CL III uses DT 350 hubs with stainless steel bearings. It adds up to a wheelset with a claimed weight of 1,555g.

Naturally there’s a difference in cost too. While the Sprint CLX and CLX III wheels are priced at $1,500 / £1,299 for the front and $2,000 / £1,699 for the rear, the CL III wheels cost $950 / £719 for the front wheel and $1,250 / £829 for the rear.