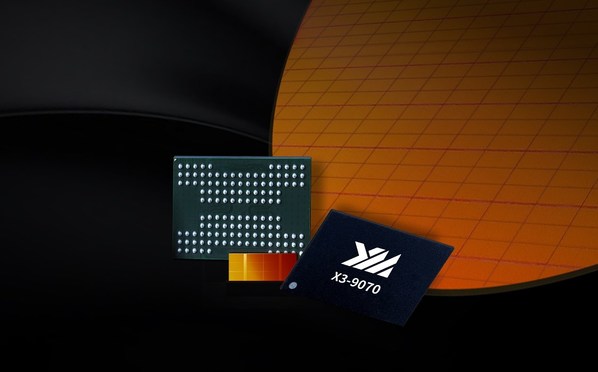

When the U.S. banned the sale of advanced chipmaking tools to Chinese entities in October 2022, China's 3D NAND champ YMTC suffered significantly as it could not get tools it had already paid for. But almost two years later, YMTC is making steady progress in replacing foreign chipmaking tools with domestically developed alternatives, according to Bloomberg which cites TechInsights.

YMTC has turned to domestic suppliers like Advanced Micro-Fabrication Equipment (AMEC), which specializes in etching equipment; Naura Technology, which focuses on deposition and etching tools; and Piotech, another deposition specialist, for chipmaking equipment. While the company continues to rely on foreign suppliers like ASML and Lam Research for key tools, these Chinese companies are increasingly shouldering a larger part of the production flow, according to TechInsights.

In recent years YMTC introduced its Xtacking 3.0 and Xtacking 4.0 architectures with up to 232 active layers and high-speed interfaces, which enabled the 3D NAND maker to stay competitive with global leaders like Micron, Samsung, and SK Hynix. Competitive enough to power some of the world's best SSDs.

Despite this progress, YMTC faces technical hurdles. Its latest NAND chip, produced using Chinese tools, has 70 fewer layers than an earlier version, largely due to lower production yields, according to Bloomberg and TechInsights. The reduced number of layers is attributed to the use of domestic equipment, which resulted in more defects during manufacturing. However, YMTC stated in an email sent to Bloomberg that it was continuously enhancing its product performance, and the variation in the number of layers in its latest devices was unrelated to the production yield of any specific equipment. Still, as soon as the number of defects decreases and yield increases, expect YMTC to increase the number of active layers.

As the U.S. continues to tighten export controls on advanced chips and equipment, China is pushing for self-reliance in this crucial sector. SMIC's and YMTC's progress is the best indicator that these efforts work. SMIC makes competitive Kirin application processors for Huawei's smartphones and is said to be making Ascend 910B processors for AI servers using its 2nd Generation 7nm process technology, whereas YMTC supplies memory to Huawei and a bunch of other customers in China. The company recently even inked a deal to supply 3D NAND memory for an SSD by U.S.-based Patriot, which promises to offer high performance at a low price.

While AMEC, Naura, and Piotech are making steady progress with more sophisticated fab tools, slowly closing the gap with leading U.S. companies like Applied Materials and Lam Research, their advancements are less seen by the general public, largely because neither they nor their clients are interested in showing their progress to the outside world in general and the U.S. in particular.

But while YMTC is adopting more domestic equipment — particularly because Chinese companies are very keen on producing competitive etching and deposition tools — the country's semiconductor industry, in general, continues to rely on foreign tools, such as those from ASML, Applied Materials, KLA, Lam Research, and Tokyo Electron.

In the first half of 2024, China became the top spender on semiconductor-making equipment as Tianxia-based chip producers invested $25 billion in new tools. This surpassed the combined investments of South Korea, Taiwan, and the U.S., highlighting China’s push to localize chip production amid fears of Western trade restrictions. By the end of 2024, China's total spending on semiconductor equipment is projected to reach $50 billion, reflecting confidence in future market demand and the industry's growth.