Across the U.S., children and adults are increasingly exposed to harmful chemicals from a source few people are even aware of.

It begins on a street outside a home or school, where a worker in a manhole is repairing a sewer pipe. The contractor inserts a resin-soaked sleeve into the buried pipe, then heats it, transforming the resin into a hard plastic pipe.

This is one of the cheapest, most common pipe repair methods, but it comes with a serious risk: Heating the resin generates harmful fumes that can travel through the sewer lines and into surrounding buildings, sometimes several blocks away.

These chemicals have made hundreds of people ill, forced building evacuations and even led to hospitalizations. Playgrounds, day care centers and schools in several states have been affected, including in Colorado, Connecticut, Massachusetts, Michigan, Pennsylvania, Washington and Wisconsin.

With the 2022 Bipartisan Infrastructure Law now sending hundreds of millions of dollars into communities across the U.S. to fix broken pipes, the number of children and adults at risk of exposure will likely increase.

For more than a decade, my colleagues and I have worked to understand and reduce the risks of this innovative pipe repair technique. In two new studies, in the Journal of Environmental Health and Environmental Science and Technology Letters, we show that workers, and even bystanders, including children, lack adequate protection.

Our research also shows the technology can be used safely if companies take appropriate action.

Fixing aging pipes with harmful chemicals

As U.S. water infrastructure ages, communities nationwide are grappling with thousands of broken sewer pipes in their 1.3 million-mile inventory.

The new law provides US$11 billion for sewer fixes, about one-fifth of the EPA’s estimate of the need.

The least expensive repair method is called cured-in-place pipe, or CIPP. It avoids the need to dig up and replace pipes. Instead, contractors insert a resin-saturated sleeve in the manhole and through the buried pipe. The resin is then “cooked,” typically with steam or hot water, and transformed into a hard plastic.

One challenge is that the resin safety data sheets do not disclose all of the chemicals, and some entirely new ones are created during heating.

Chemical plumes rising from nearby manholes and contractor exhaust pipes are also not just “steam.” These plumes contain highly concentrated chemical mixtures, uncooked resin, particulates and nanoplastics that can harm human health. When we examined the heating process in the lab, we found that as much as 9% of the resin was emitted into the air.

CIPP production is known to discharge about 40 chemicals. Some cause nausea, headaches and eye and nasal irritation. They can also lead to vomiting, breathing difficulties and other effects.

Styrene, the most frequently documented chemical, is acutely toxic, and “reasonably anticipated” to cause cancer, according to the National Research Council. Chemicals other than styrene can be responsible for plume toxicity.

CIPP-associated illnesses in nearby buildings

So far, chemical exposures have been reported in at least 32 states and seven countries. In addition to schools, this process has contaminated homes, restaurants, medical facilities and other businesses. Companies have been cited for exposing their workers to unsafe levels of styrene.

The earliest U.S. incident we know about was in 1993 at an animal shelter in Austin, Texas. Seven people were overcome by fumes and transported to a hospital. In 2001, fumes entered a hospital inn Tampa, Florida, causing employee breathing problems. Since then, hundreds more people are known to have been exposed, and the numbers are likely much higher.

In our experience, exposures are rarely made public. Municipalities have encouraged people affected by the fumes to only contact the CIPP contractor and pipe owner. In some cases, people were told the exposures were always harmless.

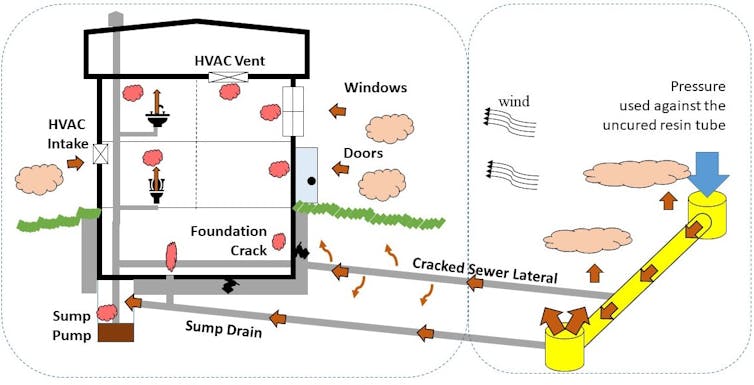

Chemicals can enter buildings through sinks, toilets, foundation cracks, doors, windows and HVAC systems. The chemicals can even enter buildings that have water-filled plumbing traps. Anticipating this risk, bystanders have been told to cover their toilets and close all windows and doors.

Wind can help dilute outdoor chemical levels. However, concentrated plumes can rush through buried pipes into nearby buildings. Bathroom vent fans may sometimes increase the indoor chemical levels. Levels that should prompt firefighters to wear respirators have been found in the buried pipes.

The highest levels have been found during and after the heating process.

Hand-held air testing devices commonly used by some firefighters and contractors do not accurately identify specific chemical levels. An earlier study showed the styrene levels were sometimes wrong by a thousandfold.

How to protect public health

With the wave of infrastructure projects coming, it’s clear that controls are needed to lower the risk that people will be harmed.

Our research points to several actions that residents, companies and health officials can take to keep communities safe.

We advise residents to:

Close all windows and doors, fill plumbing traps with water and leave the building during pipe-curing operations, especially when children are in the building.

Report unusual odors or illnesses to health officials or call 911. Seek medical advice from health officials, not the contractors or pipe owners. Evacuate buildings when fumes enter.

Companies can minimize risks too. They can:

Stop the cooking process when fumes leave the worksite to lessen the spread of contamination and exposures.

Use resins that release less air pollution than standard resins.

Ask federal agencies to evaluate hand-held air testing device use.

Capture and treat air pollution from the process. While this has not yet been done at scale, it is straightforward and would be a fraction of the overall project cost. This waste will be hazardous because of its toxicity.

Public health and environmental agencies should also get engaged. Federal agencies know that the practice poses health risks and can be fatal to workers. California and Florida recognize in safety documentation that bystanders could be harmed. But, so far, few steps have been taken to protect workers’ and bystanders’ health.

Andrew J. Whelton receives funding from the U.S. National Science Foundation. U.S. Environmental Protection Agency, U.S. Federal Highway Administration, and Purdue University. He was named in patent 11486530, which pertains to the technologies for capturing, identifying, analyzing, and addressing emissions that are potentially hazardous to the environment and humans. The invention was developed with support from the U.S. National Science Foundation.

This article was originally published on The Conversation. Read the original article.