As the manufacturing industry becomes more advanced and fast-paced, Carlos Macias stands out as a leader in blending artificial intelligence (AI) with mechanical engineering.

Drawing on years of experience streamlining production processes, he uses AI to help manufacturers tackle real challenges like predicting equipment issues, improving quality, and running operations more smoothly and efficiently.

“AI isn’t just an upgrade; it’s changing everything,” Macias explains. “It helps us make decisions faster and more accurately while giving us insights we couldn’t even imagine a few years ago.”

Macias is a dynamic engineering professional with over 20 years of experience in manufacturing leadership and process optimization. His exceptional skills lie in leveraging AI and advanced technologies to address complex challenges, streamline operations, and drive sustainable growth.

Transforming Maintenance with AI

One of Macias’s specialities is predictive maintenance, a proactive approach to equipment management that minimizes downtime and maximizes performance. Traditional maintenance strategies often rely on fixed schedules or reactive measures, leading to inefficiencies and unexpected failures.

“Waiting for a machine to break down is like waiting for a disaster to strike,” Macias points out. “Predictive maintenance changes the game by identifying issues before they happen.”

In a recent project, Macias implemented an AI-driven system in a high-volume manufacturing facility. The system used real-time data from sensors embedded in machinery to monitor performance and detect anomalies. By analyzing patterns, it predicted potential failures with over 90% accuracy, allowing the company to address problems before they caused disruptions.

The results were impressive: a 30% downtime reduction and substantial repair cost savings. “With predictive maintenance, we’re not just fixing problems; we’re stopping them before they happen,” Macias explains. “It’s about staying ahead instead of just reacting.”

Gustavo Alberto Gómez, a senior executive in the manufacturing industry, has worked alongside Macias for over 12 years. Their collaboration on innovative engineering projects has given Gustavo a deep appreciation for profound knowledge and leadership.

“Carlos is a visionary professional whose technical in-depth knowledge and innovative thinking have consistently transformed our production processes. His leadership in implementing an AI-driven production scheduling system was a standout achievement, which boosted our operational efficiency and productivity by an incredible 99.8%.

“His ability to drive such impactful results has set new benchmarks for success, and working with him has been both inspiring and rewarding,” Gomez says.

Macias also believes in the power of teaching and mentorship. He dedicated 20 years to managing the commercial and sales department at a leading producer of stamped metal parts for cars and trucks.

During his tenure, he demonstrated a remarkable ability to nurture talent, hiring inexperienced engineers, mentoring and transforming the team into skilled Business Development Engineers: “I believe in investing in people,” Macias reflects. “With the right coaching, anyone can achieve extraordinary results.”

He honed his team's expertize in customer focus, AI applications, negotiation, closing deals, empathy, accounting, and cost management through targeted training. His efforts paid off as his team successfully engaged with major vehicle assembly clients, including General Motors, Hino Motors, and Renault.

“My greatest achievement was seeing these engineers grow into confident professionals who could tackle complex client challenges,” Macias says. His legacy is defined by a commitment to fostering talent and delivering exceptional results in the automotive industry.

Real-Time Quality Control: Raising the Standard

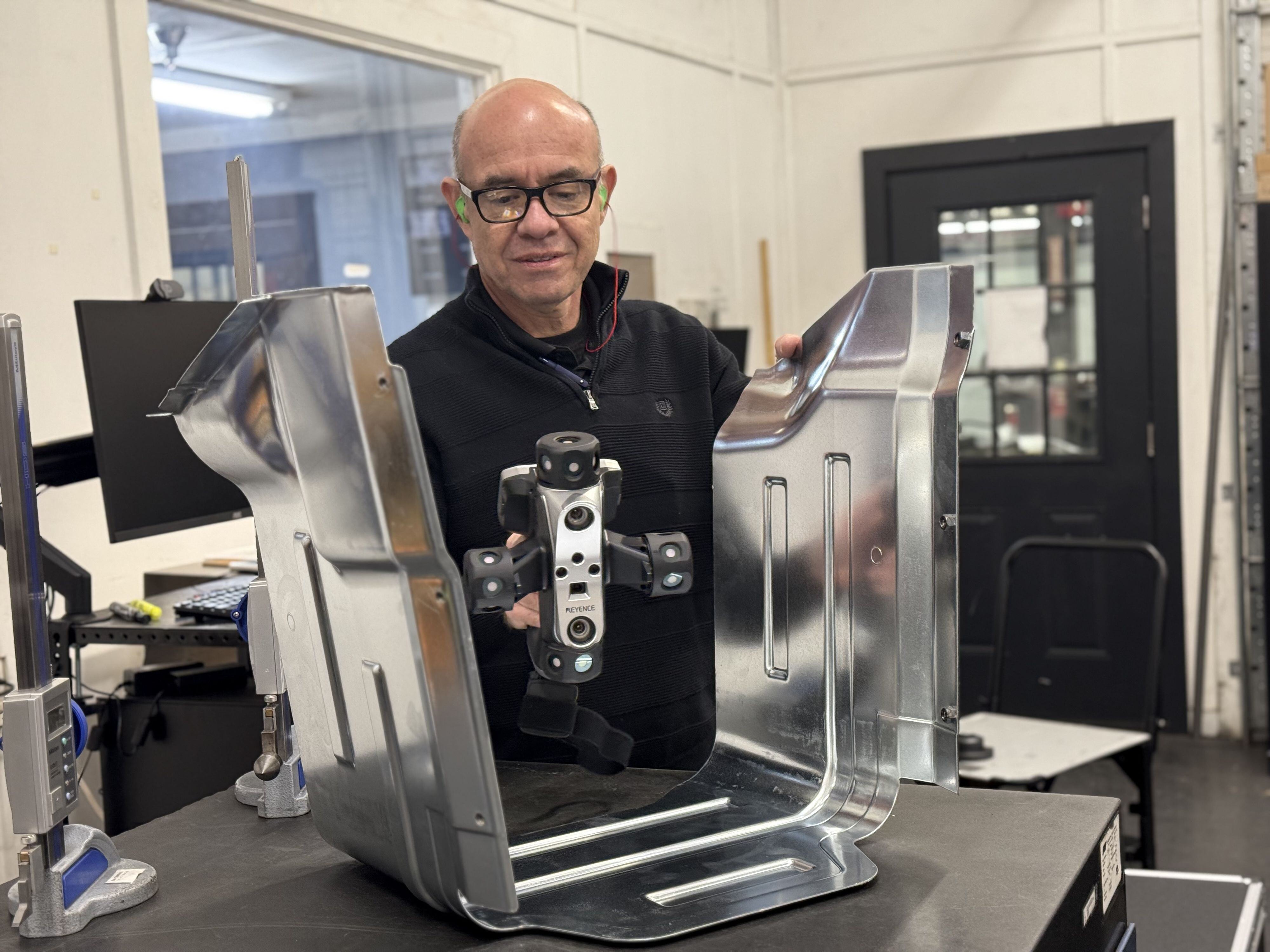

Macias has introduced AI-powered visual inspection systems that analyze products in real-time, identifying defects with unprecedented precision.

“AI doesn’t get tired, it doesn’t miss details, and it can process thousands of items in the time it takes a person to inspect a handful,” he says.

Quality control is another area where Macias has leveraged AI to deliver exceptional results. In traditional manufacturing, quality inspections are often manual, time-consuming, and prone to human error.

“Real-time quality control is about consistency,” Macias emphasizes. “It ensures that every product meets the same high standard, critical in industries where even minor imperfections can have major consequences.”

The Data Revolution in Manufacturing

At the heart of Macias’s work is data. He believes that effective use of data is what truly sets AI apart from traditional approaches. “Manufacturing generates vast amounts of data, but most of it goes unused,” he explains.

“AI turns raw data into actionable insights, helping companies optimize every aspect of their operations.”

Macias’s projects often involve integrating AI into existing manufacturing systems to extract meaningful insights. In one case, he helped a company align its production schedules with real-time demand forecasts, reducing overproduction and minimizing inventory costs.

“Data is the foundation,” he says. “AI thrives on it, and the more accurate and comprehensive the data, the better the results.”

In December 2022, Carlos led the auto parts manufacturing business to significant recognition, securing 2nd place as the best business within the corporation's group.

This achievement was attributed to his leadership in driving the best EBITDA results and sales growth, showcasing his ability to enhance operational efficiency and deliver exceptional financial performance..

Under his leadership, he successfully implemented AI-powered visual inspection systems, significantly improving quality control by reducing paint line defects by 20% and boosting production capacity.

Jorge Losada Fina, a longtime colleague and industry peer, worked closely with Macias, witnessing firsthand his unparalleled insight and dedication in the auto parts business.

“Carlos is one of the most visionary and results-driven professionals I’ve had the privilege to work with. His ability to strategically position Colombian metal stamping auto parts in the competitive US truck market was remarkable. He secured new business opportunities with American car manufacturers and consistently delivered results that elevated our business to new heights.” Losada says.

Overcoming Resistance to AI Adoption

While the benefits of AI are clear, Macias acknowledges that its adoption in manufacturing isn’t always straightforward. Resistance to change is common, especially in industries steeped in tradition.

“People fear what they don’t understand,” he notes. “There’s a misconception that AI replaces jobs, but it’s here to enhance them. AI is used in quality control, production optimization, inventory management, and scheduling.

“In welding, robots have replaced human labor, but rather than taking jobs, they’re making work more efficient. Robots that once cost $200,000 are now just $30,000, allowing employees to focus on more complex tasks while robots handle the repetitive work.”

Macias has successfully addressed concerns about AI by demonstrating its practical benefits. “Once people see how AI simplifies their work and improves outcomes, the resistance fades,” he says. He also emphasizes that collaboration between engineers, operators, and data scientists is key. “AI is a tool, but people make it work,” Macias explains.

“By involving everyone in the process, we ensure that the technology serves the business's and its workers' needs.”

Building a Sustainable Future

For Macias, the potential of AI extends beyond operational efficiency. He is deeply committed to using AI to promote sustainability in manufacturing.

"Sustainability isn’t just a buzzword; it’s a necessity," he states. "Using AI is essential in every aspect of production, helping us optimize resource use, reduce waste, and minimize our environmental impact. For me, the priority is to create a long-term sustainability strategy because having a strong strategy like this guarantees the company’s success in the future."

In one project, Macias used AI to analyze energy consumption patterns across a company’s facilities. By identifying inefficiencies, his team implemented changes that reduced energy use by 25% and lowered the company’s carbon footprint.

“AI enables us to align business goals with environmental responsibility,” Macias says. “It’s about creating solutions that are good for the planet and good for the bottom line.”

As Head of People and Strategy at IFAB Corporation, Sandra Ochoa collaborated with Carlos on transformative initiatives that leveraged AI to improve operational efficiency and drive innovation. Her experience working with Carlos highlights his exceptional problem-solving skills and technical expertise.

“Carlos’s ability to analyze complex systems and uncover inefficiencies is unparalleled,” Sandra remarks. “His innovative AI solutions not only enhance efficiency but also position manufacturers to compete globally. Carlos’s work fosters growth by integrating cutting-edge technology and upskilling teams, ensuring sustainable success for the future.”

A New Era in Manufacturing

Macias envisions a manufacturing landscape where AI is fully integrated into every process. “The future factories will be smart, connected ecosystems,” he predicts.

“AI will enable real-time decision-making, seamless collaboration, and unprecedented levels of efficiency.”

One area of particular interest for Macias is the potential for AI to drive mass customization: “AI makes it possible to produce personalized products at scale,” he explains.

“This opens up new opportunities for manufacturers to meet the evolving demands of consumers.”

He also sees AI as crucial in workforce development: “AI can handle repetitive tasks, freeing up workers to focus on creativity and problem-solving,” Macias notes. “It’s about elevating the role of people in manufacturing, not diminishing it.”

Known for his innovative approach to problem-solving and commitment to fostering teamwork, Macias has consistently enhanced efficiency and competitiveness for global manufacturers.

With a passion for integrating cutting-edge technology into traditional engineering practices, he has become a leader in implementing AI-driven solutions across diverse industries.

“AI is a tool for progress,” Macias concludes. “It’s not just about improving what we already have; it’s about redefining what’s possible. AI allows us to push boundaries, explore new opportunities, and find innovative solutions to challenges we once thought were unachievable.

Macias continues setting benchmarks in integrating AI within manufacturing, blending technological advancements with strategic insights to create more innovative, sustainable operations. His journey reflects a commitment to excellence, a drive for innovation, and an unwavering dedication to advancing the engineering profession.