Asetek — renowned for its AIO cooler pump designs — has announced a new exclusive partnership with 3D metal printing manufacturer Fabric8Labs. The pair have announced a new cold plate design optimized with AI, featuring Electrochemical additive manufacturing, drastically improving the cold plate's quality, scalability, and sustainability (recyclability).

Electrochemical additive manufacturing (ECAM) is a manufacturing technique that involves 3D metal printing at room temperature. The manufacturing process involves a water-based feedstock that contains dissolved metal ions, which enables ECAM 3D printers to build metal structures rapidly while improving the product's quality.

This new 3D printing process purportedly allows for complex, high-resolution structures that significantly improve a product's thermal capabilities through enhanced fluid dynamics. ECAM products can be built at higher fidelity, improving the product's performance over more traditional manufacturing techniques.

Not only does ECAM improve product quality/performance, but it also allows for more flexibility. Metal components 3D printed with ECAM can be printed directly onto temperature-sensitive sub-strights such as PCBs, which can speed up manufacturing and allow for fewer components in a product. In Asetek's case, it can now install circuit boards directly behind the cold plate, which could potentially reduce the size of its AIO pump housings. However, this is just a limited example of what it can do. Other issues could make this use case non-viable, such as the circuit board overheating being so close to the cold plate (which is a heat exchanger in and of itself).

In addition to these improvements, ECAM is purportedly more scalable and offers better recyclability than other metal-based manufacturing processes.

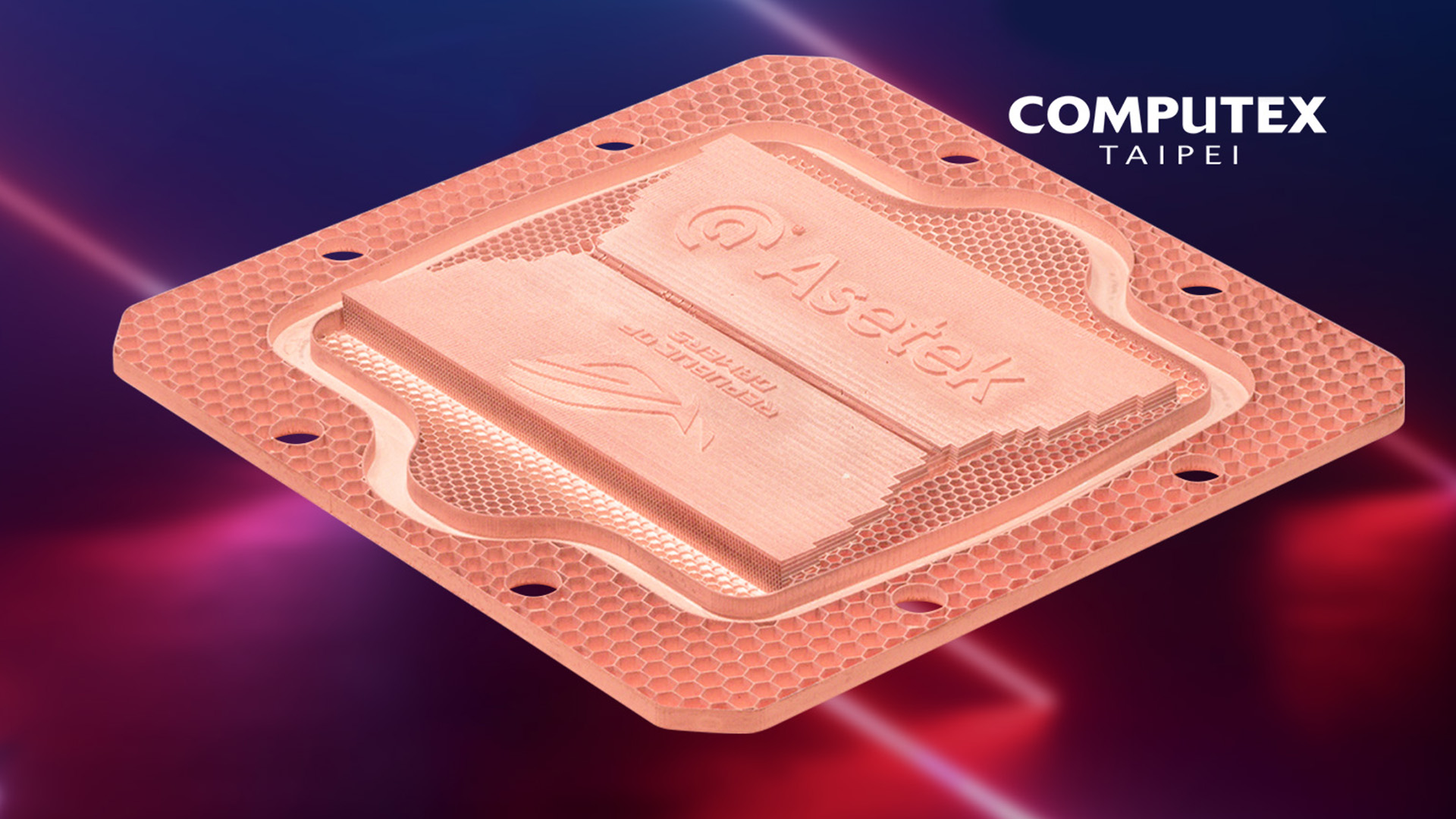

Asetek and Fabric8Labs have announced a new cold plate built on Fabric8Lab's ECAM manufacturing process. The new cold plate reportedly boasts all the advantages the new manufacturing process delivers, including better thermal characteristics, compared to Asetek's outgoing designs, which are built with traditional manufacturing techniques.

Sadly, neither party shared any detailed specifications or performance benchmarks for this new ECAM-built cold plate. However, Asetek announced that its "AI-optimized" ECAM cold plate will be featured at Computex 2024 (happening right now) at the Asus ROG booth. Depending on scheduling, we hope to have one of our people check out the booth to see Asetek's new cold plate in action.