Apple's A17 processor was the first chip to use TSMC's N3 (3nm-class) process technology, and this week, the company expanded its N3 lineup with a family of PC-oriented M3 chips for desktop and laptop computers. Analyst Jay Goldberg from Digits to Dollars believes the company spent as much as $1 billion on M3's design and tape-outs alone.

"We have to assume that [M3-series] tape out costs alone for the three [SoCs] has to be close to $1 billion," Goldberg wrote. "Very few companies can afford this large an undertaking."

Apple's M3 family consists of three fairly complex CPUs for now: the 25-billion-transistor M3 that's aimed at entry-level and mainstream desktops, laptops, and high-end tablets; the 37-billion-transistor M3 Pro for performance-mainstream machines; and the M3 Max that packs 92 billion transistors for high-end laptops and entry-level workstations. Each chip is designed to address different computing needs, from everyday tasks to professional coding, heavy engineering simulations, and video production.

Apple's vanilla M3, which comes with eight general-purpose cores and a new built-in GPU, is as complex as AMD's highly praised Phoenix processor (25 billion vs. 25.4 billion), whereas the M3 Pro and M3 Max are considerably more complex.

In fact, with 92 billion MOSFETs inside, the M3 Max is the most complex single-die processor released to date (though, based on what we know about some of the upcoming AI processors, not for long).

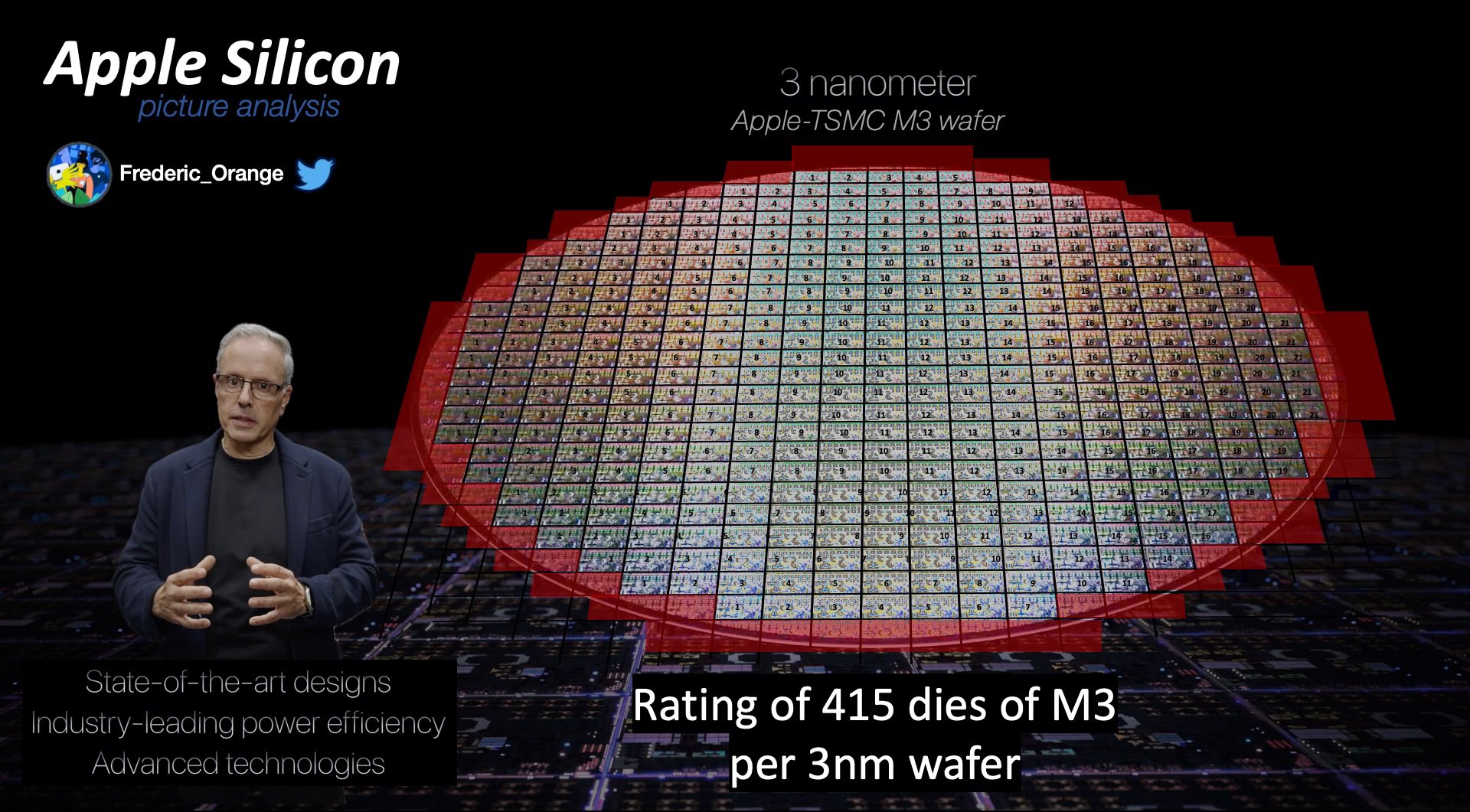

Apple used TSMC's N3 fabrication process to increase the economic efficiency of its M3 family, a risky move because the technology is relatively new -- but it looks like it has paid off. As chip detective @Frederic_Orange pointed out, Apple could presumably fit as many as 415 M3 dies on a single 300-mm wafer, which indicates a die size of around 146 mm^2.

By contrast, AMD's Phoenix (which has a similar complexity) has a die size of 178 mm^2. We can only guess whether Apple's M3 is cheaper to make than AMD's Phoenix based on rumors about TSMC's quotes, but smaller chips are typically easier to yield and produce.

Apple spent $26.251 billion on R&D in 2022, and a significant part of this spending was assigned to chip design. The scale of investment in silicon, in general, and the M3-series SoCs, in particular, indicates that Apple is one of the few companies with the economic capability to undertake such development endeavors.

Developing complex PC-oriented processors requires extended development cycles, often on the order of years, and intense capital investment. When it comes to an all-new platform — such as the Apple M3 family — the cost of development is staggering, particularly in Apple's case since the company tends to develop as much IP internally as possible. With M3, Apple not only uses its own custom general-purpose cores based on an Arm instruction set architecture but also packs an all-new GPU architecture supporting hardware-accelerated ray tracing and mesh shaders, a new AI NPU, and a new multimedia engine.