The British hill climb racing scene thrives on a passionate, grassroots culture that brings cyclists and fans together to celebrate the raw challenge of ascending steep, relentless gradients.

But while the racing itself can be quite the spectacle, the bikes on which riders tackle the double-digit gradients are also often rather eye-catching. With the events falling under the Cycling Time Trials (CTT) ruling rather than UCI ruling, bikes don't have to meet a minimum weight limit, nor do they have to have drop handlebars, and as a result, the UK hill climbing scene shows off some of the best garage-built bikes in the world.

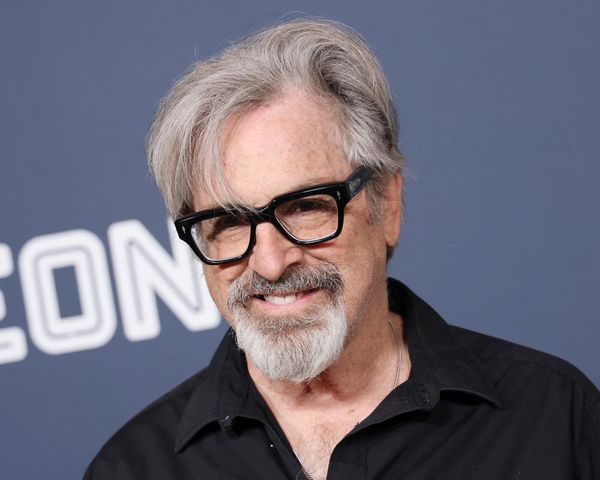

And today we're taking a look at the totally nonstandard bike belonging to hill climb veteran, Andy Nichols of Team Lifting Gear Products. The mismatched wheels, chopped handlebars and a very very short chain might not look like carefully considered performance choices, but there is a meticulous method behind this rather wild-looking bike build.

This single purpose racing machine is almost completely non-standard, but as usual, we'll start with the heart of the bike, the frameset.

Nichols built the bike around the last generation rim brake Orbea Orca frameset, which might be a few years old now, but still manages to help achieve an overall bike weight of 5.70kg.

The groupset is where the game of spot the non-standard components becomes a whole lot easier. Nichols' groupset started off life as a Shimano Ultegra 6800 Di2 groupset, which hit the shelves over a decade ago now. Thanks to some rather extreme modifications though, you'd be forgiven for not recognizing the Shimano engineering.

A carbon fiber mech cage has been added to save weight at the rear, while the front chainring has been switched out for an oval chainring, which Nicholls prefers for his out of the saddle riding style on steep climbs. The chain has also been upgraded (and shortened) to a KMC X11 SL, adding a bit of bling to the bike.

Up front, the shifters too have been well and truly butchered. In a bid to save a precious 30 grams, Nichols has forgone the comfort of the rubber shifter hood covers on his handlebars, instead opting for just a single wrap of electrical tape. It's not the most comfortable, and potentially slippery when wet, but certainly committing to saving every gram possible.

The Bontrager XXX handlebar and stem combination has been chopped too. Nichols prefers to climb on the hoods, making the drops redundant, and therefore considered as excess weight. We estimate this mod saves around 40-60 grams on a lightweight handlebar such as the Bontrager XXX.

As the hill climbing season is so short, riders only tend to get to use their specialist bikes for about 2 months of the year, meaning many build their bikes on a strict budget. Nichols too has made some cost effective purchases on his bike from online retailer AliExpress - not always synonymous with quality...

Nichols described the bike build as an 'Ode to AliExpress', with the saddle, seatpost, and perhaps most worryingly the brake callipers all coming from the online store and costing no more than $20 per item.

Underneath the rather uncomfrotable looking carbon saddle, you'll also find a tiny LED light that has been bonded onto the bike. While CTT doesn't have a minimum weight limit, it does require all riders to use a front and rear bike light in competition, so Nichols found this incredibly lightweight option to abide by the rules.

Now then let's tackle what seems like a rather strange wheel setup for hill climbing. Instead of opting for all out weight saving, Nichols has fitted an 80mm front wheel to his bike to improve aerodynamics. Speaking to Cycling Weekly, Nichols said that following some very 'unscientific testing', he concluded that on certain courses, having a faster front wheel was actually more important than a super light low profile one like the rear wheel.

With the front wheel having a larger impact than the rear wheel, Nichols settled on this balanced approach, completing a totally bespoke build that any true bike fettler can appreciate.