Research on new methods of fabrication is never-ending, and Caltech researchers have recently made another major discovery. Following Caltech's fabrication method, metallic materials as small as 150 nanometers (comparable to a flu virus and certainly invisible to the naked eye) can be created with three-to-five times the sturdiness of similarly-sized materials.

So, why is 3D printing metal with this method so good? First, let's discuss the downsides of creating materials so small to begin with. At an atomic level, these nano materials actually have a "very, very messy microstructure", with issues that would lead to serious defects in larger metal objects.

But when operating at nanoscale, the rules are a little different. A "perfect," defect-free nano-pillar would inevitably collapse from contact with itself, while one full of "defects" actually enjoys a massive boost to fault tolerance. According to Wenxin Zhang, lead author of the original paper, the existence of interior "pores" allow for faults to be terminated near-immediately instead of weakening the entirety of the structure.

So, what does all this mean? Well, for one, it means physics gets really weird at a nano-scale and the further tech progresses down this road, the more often we'll be finding strange, contradictory rules like this one. But secondly and more importantly, a lot of very useful things can be created this way, including nano-scale sensors, heat exchangers, and more.

And of course, while this technically counts as 3D printing, it's very unlikely that any of the best 3D printers for consumers will be capable of creating nanoscale materials anytime soon, especially not with the specific fabrication process being used at the Caltech labs.

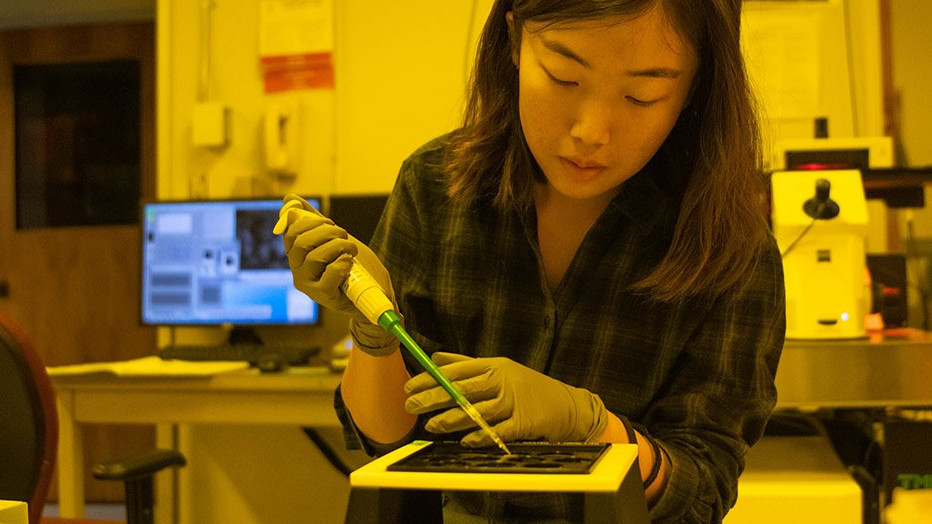

The process is very complicated and involves building a photosensitive mixture that includes a hydrogel polymer, hardening that mixture with a laser, infusing the substance with another solution that has nickel ions, baking it and chemically stripping oxygen atoms out of the parts, among other things. For more details, check out Zhang's paper.